-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ต.ค. . 13, 2024 22:18 Back to list

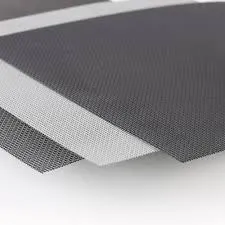

hot dip galvanized wire mesh manufacturers

Understanding Hot-Dip Galvanized Wire Mesh A Comprehensive Overview

Hot-dip galvanized wire mesh has gained prominence in various applications due to its exceptional durability and resistance to corrosion. This type of wire mesh is extensively used in industries ranging from agriculture and construction to security and fencing. Consequently, the demand for hot-dip galvanized wire mesh manufacturers has surged, leading to a need for a deeper understanding of this product and its manufacturing processes.

What is Hot-Dip Galvanizing?

Hot-dip galvanizing is a process in which steel or iron is coated with a layer of zinc to protect it from corrosion. This method involves immersing the metal in molten zinc, forming a strong metallurgical bond that enhances its resistance to environmental factors. The result is a robust wire mesh that can withstand harsh weather conditions, chemicals, and physical abrasions.

Benefits of Hot-Dip Galvanized Wire Mesh

1. Corrosion Resistance The primary advantage of hot-dip galvanized wire mesh is its superior corrosion resistance. The zinc coating protects the steel from rust, which is a significant concern in outdoor applications. This makes it an ideal choice for fencing, agricultural structures, and industrial applications exposed to moisture.

2. Longevity Products that utilize hot-dip galvanized wire mesh have an extended service life. Depending on the environmental conditions, these meshes can last for decades without significant degradation. This longevity translates into cost savings, as consumers do not need to frequently replace fencing or protective structures.

3. Versatility Hot-dip galvanized wire mesh is available in various sizes and types, including welded wire mesh, woven wire mesh, and more. This versatility allows manufacturers to cater to specific needs across multiple industries, whether for construction reinforcements, animal enclosures, or architectural applications.

4. Aesthetic Appeal Besides functionality, hot-dip galvanized wire mesh presents a visually appealing finish, making it suitable for decorative applications. It retains a bright, shiny surface that can enhance the look of structures like fences and garden trellises.

The Manufacturing Process

hot dip galvanized wire mesh manufacturers

The production of hot-dip galvanized wire mesh involves several key steps

1. Wire Preparation The process begins with the preparation of the steel wire, which is cleaned to remove any oils, dirt, or oxidation. This ensures proper adhesion of the zinc coating.

2. Galvanizing The cleaned wire is then immersed in a bath of molten zinc, where the coating is applied. The temperature of the zinc bath typically ranges from 830°F to 860°F (about 450°C to 460°C). The immersion time can vary depending on the desired thickness of the coating.

3. Cooling and Inspection After galvanizing, the wire is cooled, allowing the zinc to solidify and form a strong bond. Manufacturers conduct thorough inspections to ensure that the wire mesh meets quality standards and specifications.

4. Fabrication Once the wire has been coated, it can be fabricated into various types of mesh, including welded or woven forms, depending on the intended application.

Choosing the Right Manufacturer

When sourcing hot-dip galvanized wire mesh, selecting a reliable manufacturer is crucial. Key factors to consider include

- Quality Assurance Ensure that the manufacturer adheres to strict quality control measures and industry standards. - Customization Options Choose a supplier that can provide tailored solutions to meet specific project requirements. - Customer Support A reputable manufacturer should offer excellent customer service, guiding buyers through the selection and ordering process.

Conclusion

Hot-dip galvanized wire mesh is a valuable material that offers numerous benefits across various industries. Its resistance to corrosion, longevity, and versatility make it a top choice for many applications. By understanding the manufacturing process and the advantages of this product, consumers can make informed decisions when selecting a hot-dip galvanized wire mesh supplier. With proper sourcing and application, businesses and individuals alike can leverage the strength and durability of this essential material.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025