-

+86 15030157877

-

sales@galvanizedmetalmesh.com

พ.ย. . 22, 2024 14:19 Back to list

square mesh factory

The Rise of Square Mesh Factory Innovations and Applications

In today’s manufacturing landscape, a square mesh factory stands out as a pivotal player in the production of high-quality lattice materials. Square mesh, known for its strength and versatility, is utilized across various industries, including construction, agriculture, and manufacturing. This article explores the significance of square mesh factories, their innovative processes, and the wide-ranging applications of square mesh products.

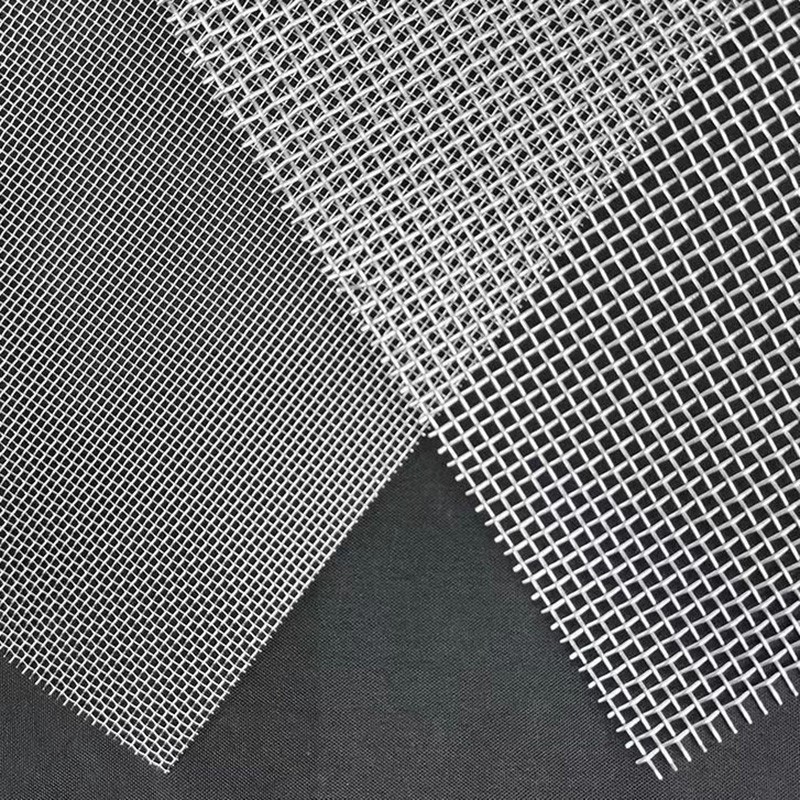

Square mesh is characterized by its grid-like structure, created from materials such as stainless steel, aluminum, or plastic. The uniformity of square openings provides excellent stability and makes it ideal for applications requiring ventilation, filtration, or security. The manufacturing process involves weaving or welding together wires to form a robust mesh that can withstand considerable stress and strain. The precision and quality of production are crucial, necessitating advanced technology and skilled labor.

One of the key innovations in square mesh factories is the adoption of automated machinery and computer-aided design (CAD) software. These technologies enable manufacturers to create customized mesh solutions tailored to specific client needs. For instance, construction companies may require high tensile strength mesh for scaffolding, while agricultural enterprises look for fine mesh to protect crops from pests. By leveraging automation, factories can enhance production efficiency, reduce waste, and maintain consistent quality, ultimately leading to cost savings.

Moreover, environmental sustainability has become a focal point for modern square mesh factories. Many manufacturers are adopting eco-friendly practices, such as sourcing recycled materials and optimizing energy consumption during production. By prioritizing sustainable practices, square mesh factories contribute to the circular economy, ensuring that resources are used responsibly and waste is minimized.

square mesh factory

The applications of square mesh are diverse and increasing. In the construction industry, square mesh is commonly used in reinforced concrete to improve durability and structural integrity. It is also employed in guardrails, fencing, and safety barriers, providing security and protection in both urban and rural settings. In agriculture, square mesh serves as a protective barrier against wildlife, helping farmers safeguard their crops while allowing air and sunlight to penetrate.

In the realm of filtration and separation, square mesh is invaluable. It is utilized in water treatment facilities, aiding in the removal of debris and contaminants. Additionally, it plays a crucial role in various manufacturing processes, where it is used to sift materials or separate particles based on size.

As the demand for high-quality square mesh products continues to grow, square mesh factories are poised for further expansion and innovation. The integration of smart technology, such as IoT and artificial intelligence, promises to enhance operational capabilities and optimize production processes. This technological evolution will not only improve quality control but also facilitate real-time monitoring, allowing factories to respond swiftly to market demands.

In conclusion, square mesh factories represent a vital segment of the manufacturing industry, driven by innovation and adaptability. Their ability to produce versatile, durable, and sustainable mesh products ensures they remain crucial to various sectors, contributing to safety, efficiency, and environmental stewardship. As technology advances and industries evolve, the role of the square mesh factory will undoubtedly expand, paving the way for new opportunities and applications in the future.

-

Custom Square Wire Mesh - High Quality, Wholesale Supply

NewsAug.15,2025

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025