-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ต.ค. . 22, 2024 02:31 Back to list

square wire mesh factories

Understanding Square Wire Mesh Factories A Comprehensive Overview

Square wire mesh, often referred to as square mesh or grid mesh, is a versatile product utilized in various industries for numerous applications. It is typically constructed from metal wires that are welded or woven together to form a grid pattern. This article delves into the significance of square wire mesh factories, shedding light on their operations, products, and the various applications of square wire mesh.

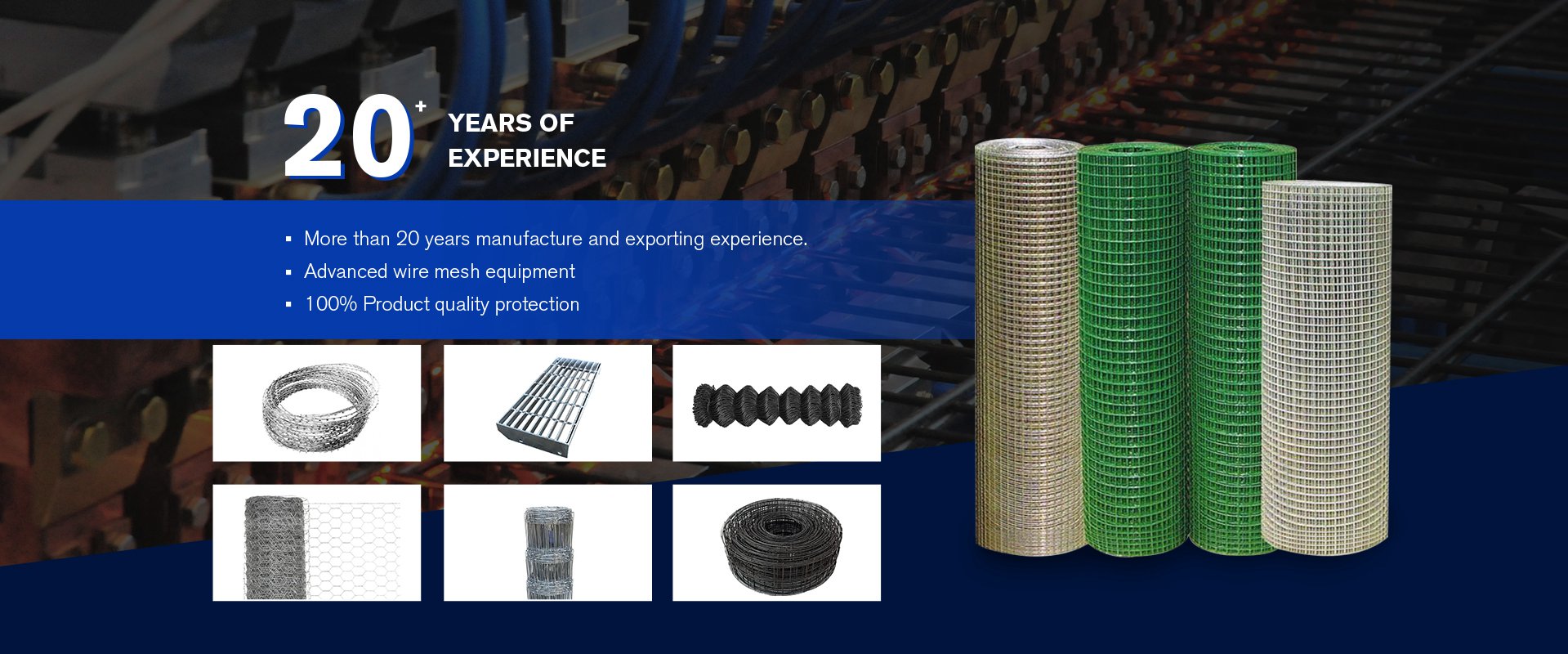

Square wire mesh factories specialize in the production of wire mesh products that feature uniform square openings. These factories source high-quality raw materials, such as stainless steel, galvanized iron, or PVC-coated wires, ensuring the final product is durable and resistance to environmental factors. The manufacturing process generally involves wire drawing, weaving, and welding, depending on the type of mesh being produced. Advanced technologies and automated machinery are often employed to enhance efficiency, ensuring consistent quality across batches.

The applications of square wire mesh are extensive. One of the primary uses is in construction and engineering, where it acts as reinforcement for concrete structures. The mesh provides stability and support, helping to prevent cracking and increasing the overall strength of the concrete. Additionally, it is commonly used in fencing, providing secure barriers for commercial and residential properties.

square wire mesh factories

In agriculture, square wire mesh serves several purposes, including animal containment, crop protection, and greenhouse construction. Farmers utilize this mesh to create fences that safeguard livestock and crops from predators or harsh weather conditions. In landscaping, square wire mesh is also used to create decorative fences or trellises for climbing plants.

Furthermore, square wire mesh is essential in various industrial applications. Filtration systems, for instance, often incorporate this mesh to filter particles from liquids or gases. Its uniform openings allow for the efficient separation of materials, making it critical in industries such as food processing, wastewater treatment, and chemical production.

The demand for square wire mesh continues to rise, driven by its versatility and functional attributes. Manufacturers are constantly innovating, producing meshes with varying thicknesses, coatings, and designs to cater to specific industry requirements. This adaptability makes square wire mesh an essential material in modern manufacturing and construction.

In conclusion, square wire mesh factories play a vital role in supplying a product that is integral to numerous sectors, from construction and agriculture to filtration and industrial applications. As industries evolve and demand for high-quality materials increases, these factories are expected to innovate and expand their offerings, ensuring that square wire mesh remains a reliable choice for various applications worldwide. The ongoing improvements in manufacturing technologies will further enhance the quality and efficiency of square wire mesh production, solidifying its importance in contemporary material use.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025