-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ก.ย. . 28, 2024 17:26 Back to list

stainless steel crimped wire mesh factories

Understanding Stainless Steel Crimped Wire Mesh Factories

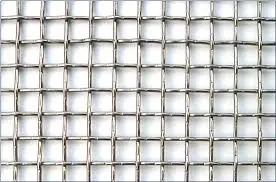

Stainless steel crimped wire mesh is a versatile and durable material widely used in various industrial applications. As industries continue to evolve, the demand for high-quality wire mesh has surged, resulting in the proliferation of factories dedicated to its production. This article explores the importance of stainless steel crimped wire mesh factories and the unique features that set them apart.

What is Stainless Steel Crimped Wire Mesh?

Stainless steel crimped wire mesh is made by weaving stainless steel wires together, resulting in a robust and stable grid structure. The wires are crimped or bent before weaving, which enhances the strength and stability of the mesh. Its resistance to corrosion and high temperatures makes it ideal for use in harsh environments, such as mining, food processing, and architecture.

The Role of Factories in Production

Factories specializing in stainless steel crimped wire mesh play a crucial role in ensuring the quality and consistency of the product. These facilities are equipped with advanced machinery and technology that enable precise wire cutting, crimping, and weaving. Skilled technicians oversee the production process, ensuring that each mesh sheet meets industry standards and customer specifications.

stainless steel crimped wire mesh factories

Quality control is paramount in these factories. They often implement rigorous testing methods to assess the strength, durability, and corrosion resistance of the wire mesh. This attention to detail not only satisfies regulatory requirements but also builds trust with customers who rely on the material for critical applications.

Innovation and Customization

Stainless steel crimped wire mesh factories are not just focused on mass production; they often emphasize innovation and customization. Many factories offer bespoke solutions to meet the specific needs of their clients. This can include different wire diameters, mesh sizes, and crimp patterns, allowing customers to choose a product that best suits their requirements.

Moreover, factories are increasingly adopting sustainable practices. Many now source raw materials responsibly and employ eco-friendly manufacturing processes. This is particularly important in today’s environmentally conscious market, where customers prefer products that align with sustainability principles.

Conclusion

In conclusion, stainless steel crimped wire mesh factories are essential players in the production of one of the most versatile materials in various industries. With their focus on quality, innovation, and customization, these factories not only meet the current demand but also pave the way for future developments in wire mesh technology. As industries expand and diversify, the role of these factories will continue to evolve, ensuring that high-quality stainless steel crimped wire mesh remains at the forefront of industrial applications.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025