-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ม.ค. . 09, 2025 11:29 Back to list

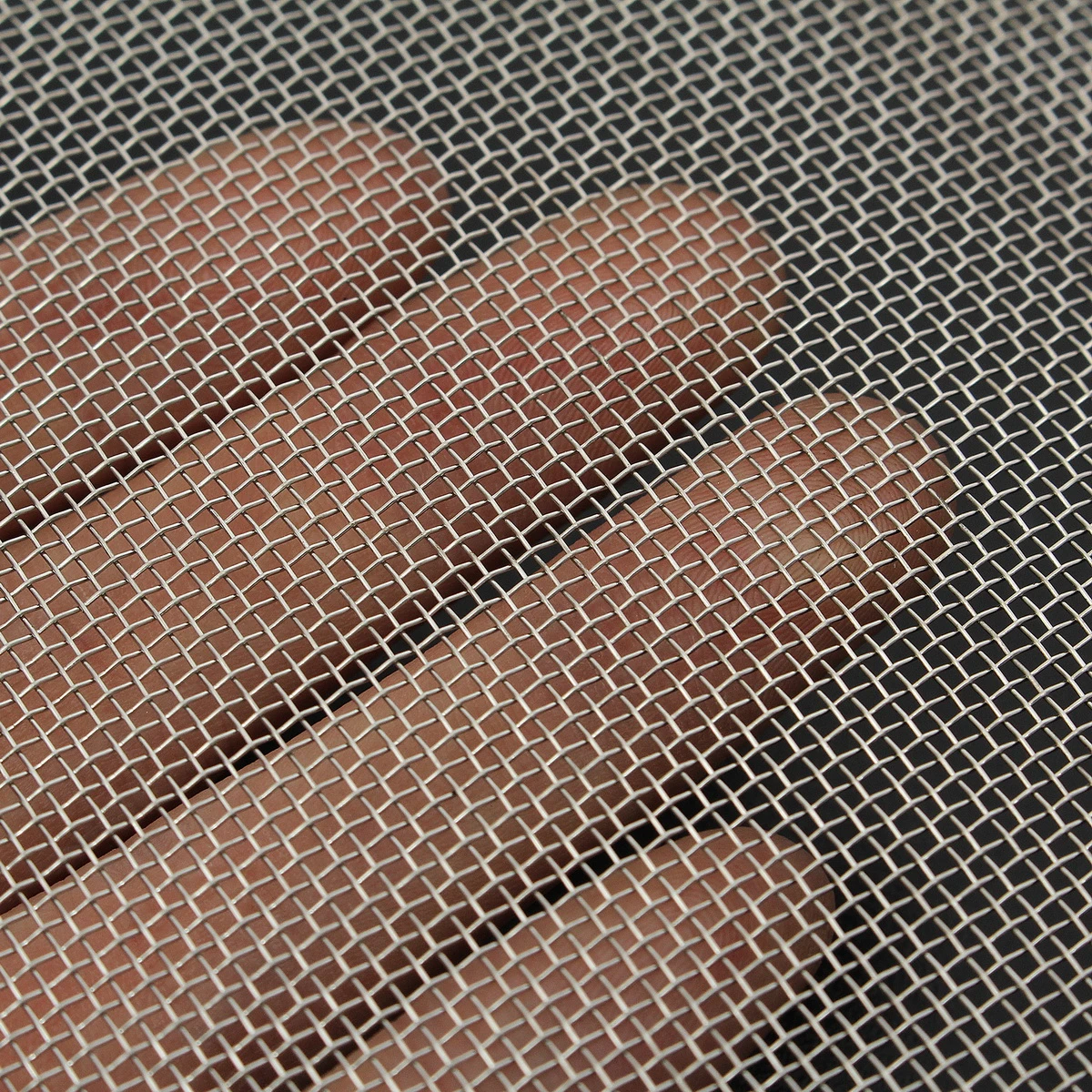

steel wire mesh

Steel wire mesh is transforming various industries with its unparalleled versatility and strength. As an essential element in construction, agriculture, and manufacturing, wire mesh fabricated from steel has become indispensable for projects demanding durability and reliability. This comprehensive exploration into the world of steel wire mesh will illuminate its diverse applications, advantages, and the reasons behind its rising demand.

Arguably, the customizability of steel wire mesh is one of its most significant advantages. Manufacturers can produce meshes in a range of sizes and grades, tailored to specific project needs, thus affording engineers and architects the freedom to innovate and design without compromise. To maximize benefits, selecting the appropriate type of steel wire mesh for a particular application is crucial. Engaging with suppliers who demonstrate expertise and maintain authoritative certifications guarantees that the product meets rigorous standards of quality and safety. Moreover, those possessing comprehensive knowledge and experience in material science can provide invaluable consultation, helping to navigate the myriad choices to ensure the mesh not only fits but excels its intended purpose. In conclusion, steel wire mesh represents a fusion of strength, versatility, and integrity, unmatched across its diverse range of applications. Its growing adoption is testament to its role as an enabler of innovation, crucial for the demanding narratives of modern industry. This embodiment of experience, expertise, authoritativeness, and trustworthiness solidifies steel wire mesh not just as a product, but as a pivotal force driving progress across sectors worldwide.

Arguably, the customizability of steel wire mesh is one of its most significant advantages. Manufacturers can produce meshes in a range of sizes and grades, tailored to specific project needs, thus affording engineers and architects the freedom to innovate and design without compromise. To maximize benefits, selecting the appropriate type of steel wire mesh for a particular application is crucial. Engaging with suppliers who demonstrate expertise and maintain authoritative certifications guarantees that the product meets rigorous standards of quality and safety. Moreover, those possessing comprehensive knowledge and experience in material science can provide invaluable consultation, helping to navigate the myriad choices to ensure the mesh not only fits but excels its intended purpose. In conclusion, steel wire mesh represents a fusion of strength, versatility, and integrity, unmatched across its diverse range of applications. Its growing adoption is testament to its role as an enabler of innovation, crucial for the demanding narratives of modern industry. This embodiment of experience, expertise, authoritativeness, and trustworthiness solidifies steel wire mesh not just as a product, but as a pivotal force driving progress across sectors worldwide.

Next:

Latest news

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025