-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ก.ค. . 15, 2025 14:11 กลับไปที่รายการ

What Are the Key Applications and Advantages of Specialized Wire Mesh Solutions?

In industrial, commercial, and residential settings, wire mesh products play a critical role in safety, security, and functionality. Among the most versatile options are stainless steel welded wire mesh, galvanized welded wire mesh panel, 4x8 wire mesh panel, welded wire mesh panel, and flexible and soft stainless steel wire mesh. Each of these solutions offers unique properties tailored to specific needs, from corrosion resistance to structural adaptability. This exploration delves into their characteristics, uses, and the factors that make them indispensable in various applications.

Exploring the Durability of Stainless Steel Welded Wire Mesh

Stainless steel welded wire mesh is prized for its exceptional resistance to corrosion and harsh environments. Composed of high - grade stainless steel wires joined at each intersection, this mesh maintains its integrity in humid, salty, or chemically aggressive settings. In food processing facilities, stainless steel welded wire mesh is used for conveyor belts or sieving materials, ensuring compliance with hygiene standards and longevity even when exposed to cleaning agents or moisture. In architectural applications, it serves as a decorative screen or security barrier for buildings in coastal areas, where salt air would degrade lesser materials. The mesh’s strength and sleek appearance make it a preferred choice for both functional and aesthetic purposes.

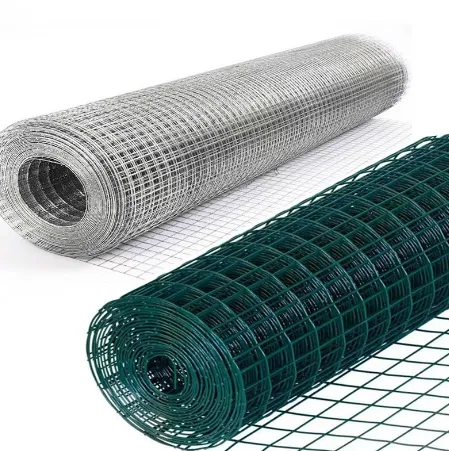

Examining the Protective Qualities of Galvanized Welded Wire Mesh Panel

Galvanized welded wire mesh panel offers a cost - effective solution for applications requiring robust protection. The galvanization process coats the steel wires with a layer of zinc, enhancing resistance to rust and extending the panel’s lifespan. These panels are commonly used in agricultural settings to fence livestock or protect crops from wildlife, as the galvanized coating withstands exposure to outdoor elements. In construction, galvanized welded wire mesh panel serves as formwork for concrete reinforcement or as a safety barrier on job sites, providing structural support while resisting corrosion from moisture or concrete chemicals. Their prefabricated size and rigidity make installation quick and efficient for large - scale projects.

Assessing the Practicality of 4x8 Wire Mesh Panel

The 4x8 wire mesh panel is a standard size that balances versatility with ease of use. This dimension is ideal for applications where uniformity and compatibility are essential, such as fencing, garden enclosures, or industrial 筛分. In residential gardens, a 4x8 wire mesh panel can be installed as a trellis for climbing plants or as a barrier to protect vegetable beds from pests. In warehouses, these panels are used to create storage partitions or security cages for equipment, leveraging their size to cover large areas without complex cutting or fitting. The 4x8 format is also popular in transportation, as it fits standard truck beds for easy delivery, reducing logistics challenges for buyers.

Understanding the Design Flexibility of Welded Wire Mesh Panel

Welded wire mesh panel stands out for its structural stability and customizable design. The welded joints at each intersection provide superior strength compared to woven meshes, making it suitable for load - bearing applications. These panels can be fabricated with varying wire gauges and mesh sizes to meet specific requirements—from fine meshes for insect screens to heavy - duty panels for machinery guards. In industrial settings, welded wire mesh panel is used as a protective covering for ventilation systems or as a safety barrier around conveyor belts, ensuring operator safety while allowing airflow. The ability to cut and shape the panels on - site further enhances their adaptability to unique project needs.

Highlighting the Versatility of Flexible and Soft Stainless Steel Wire Mesh

Flexible and soft stainless steel wire mesh offers a unique combination of malleability and strength. Unlike rigid meshes, this type can be bent, shaped, or wrapped around irregular surfaces without breaking, making it ideal for artistic installations, decorative filters, or applications requiring conformability. In automotive manufacturing, it may serve as a gasket or sealant in engines, adapting to complex geometries while resisting high temperatures and vibrations. In interior design, flexible and soft stainless steel wire mesh is used as a room divider or ceiling feature, its soft texture adding a modern, industrial aesthetic to spaces. The flexibility does not compromise durability, as the stainless steel material still provides excellent resistance to wear and corrosion.

FAQ: Key Insights into Specialized Wire Mesh Solutions

How to Select the Right Material for a Wire Mesh Project?

Choosing between stainless steel welded wire mesh, galvanized welded wire mesh panel, or other options depends on the environment and requirements. For high - corrosion settings like coastal areas or chemical plants, stainless steel welded wire mesh is optimal. For budget - conscious outdoor applications, galvanized welded wire mesh panel offers reliable protection at a lower cost. Consider factors like moisture exposure, load - bearing needs, and aesthetic goals to determine the best material.

What Maintenance Is Required for Galvanized Welded Wire Mesh Panels?

Galvanized panels require minimal maintenance due to their protective zinc coating. Periodically inspect for scratches or chips in the coating, especially in high - abrasion areas, and touch up with a zinc - rich paint to prevent rust. Clean the panels with a mild detergent and water to remove debris, avoiding harsh chemicals that could damage the galvanized layer. Regular checks ensure the panels maintain their corrosion resistance over time.

Can 4x8 Wire Mesh Panels Be Customized for Non - Standard Sizes?

While 4x8 wire mesh panel is a common size, most manufacturers offer customization services. Panels can be cut to smaller dimensions or joined together to create larger barriers. For unique projects, specify the required length, width, wire gauge, and mesh size to ensure the panel fits perfectly. Customization is particularly useful for irregularly shaped areas or specialized industrial applications.

Where Is Flexible and Soft Stainless Steel Wire Mesh Best Used?

Flexible and soft stainless steel wire mesh excels in applications requiring adaptability, such as wrapping around curved surfaces, creating decorative sculptures, or serving as a filter in irregularly shaped containers. It is also suitable for environments where a balance of flexibility and corrosion resistance is needed, like marine applications or food processing equipment that requires frequent bending or adjustment.

What Factors Influence the Cost of Welded Wire Mesh Panels?

Costs for welded wire mesh panel depend on material (stainless steel is more expensive than galvanized steel), wire gauge (thicker wires increase cost), mesh density (finer meshes require more material), and panel size. Customizations, such as special coatings or non - standard dimensions, can also affect pricing. Comparing quotes from suppliers and defining project requirements clearly helps in optimizing costs without compromising quality.

-

Stainless Steel Wire Mesh | 304/316, Factory Direct Prices

ข่าวNov.17,2025

-

Stainless Steel Wire Mesh – Durable, Rust-Resistant, Exact

ข่าวNov.17,2025

-

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

ข่าวNov.17,2025

-

Security Window Screen Mesh | Stainless Steel, Anti-Theft

ข่าวNov.17,2025

-

Anti Bird Spikes Exporter – Durable Humane OEM Wholesale

ข่าวNov.17,2025

-

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

ข่าวNov.11,2025