-

+86 15030157877

-

sales@galvanizedmetalmesh.com

ต.ค. . 16, 2024 03:40 Back to list

Wire Mesh Manufacturing Factories for SS 316 and 304 Materials

The World of Stainless Steel Wire Mesh SS 316 and SS 304 Factories

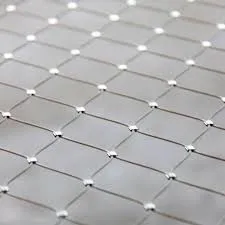

Stainless steel wire mesh is an essential material used across various industries, thanks to its durability, resistance to corrosion, and flexibility in application. Among the many stainless steel grades available, SS 316 and SS 304 are the most popular. These materials are commonly produced in specialized factories that focus on high-quality wire mesh production.

Understanding SS 304 and SS 316

Before delving into the manufacturing process, it’s important to understand the differences between SS 304 and SS 316 stainless steels.

SS 304, also known as 18-8 stainless steel, contains 18% chromium and 8% nickel. This composition makes it highly resistant to oxidation and corrosion, particularly in indoor environments. SS 304 is often used in food processing, kitchen equipment, and some architectural applications due to its excellent weldability and formability.

On the other hand, SS 316 is enriched with an additional 2% molybdenum, which significantly enhances its resistance to saltwater and acidic solutions. This property makes SS 316 the ideal choice for marine environments, chemical processing plants, and any application exposed to harsh conditions. The increased corrosion resistance makes SS 316 wire mesh a preferred option for many industries.

The Manufacturing Process

The production of stainless steel wire mesh involves several essential steps, starting from raw material procurement to the final inspection of the product. Factories that specialize in manufacturing SS 316 and SS 304 wire meshes typically follow these steps

1. Material Sourcing Quality stainless steel billets are sourced from reputable suppliers. The raw materials are assessed for compliance with industry standards to ensure that they provide the desired properties in the final product.

2. Wire Drawing The raw stainless steel billets are then processed through a wire drawing machine. This machine pulls the stainless steel through a series of dies that gradually reduce its diameter, transforming it into wire rods of different gauges.

wire mesh ss 316 304 factories

3. Mesh Weaving Next comes the weaving process. Based on the intended application, different weaving patterns can be employed, such as plain weave, twill weave, or dutch weave. The choice of pattern will affect the strength, filtration capabilities, and appearance of the wire mesh.

4. Finishing and Treatments After weaving, the wire mesh may undergo several finishing processes. These can include cutting to size, surface treatment (such as pickling or passivation), and sometimes additional coatings to enhance durability or specific performance characteristics.

5. Quality Control Rigorous quality control procedures are crucial in wire mesh manufacturing. Each batch is tested against various standards for tensile strength, corrosion resistance, and dimensional accuracy. This ensures that the wire mesh meets the required specifications and can perform effectively in its intended application.

6. Packaging and Distribution Once the mesh has passed quality inspections, it is packaged carefully to prevent damage during transportation. Factories often have a network of distributors to ensure timely delivery to clients worldwide.

The Role of Factories in the Industry

Factories producing SS 304 and SS 316 wire mesh play a crucial role in meeting the diverse demands of various industries. Their capabilities extend beyond mere production; they often provide customized solutions tailored to client specifications. This adaptability is vital in sectors such as construction, filtration, food processing, and marine applications, where specific attributes of wire mesh are required.

Moreover, a focus on sustainability has led many factories to implement eco-friendly practices in their operations. By optimizing production processes and utilizing recyclable materials, these factories contribute to reducing environmental impact while maintaining high standards of quality.

Conclusion

In summary, stainless steel wire mesh, especially SS 304 and SS 316 varieties, is fundamental across multiple sectors, thanks to its strength, durability, and resistance to harsh conditions. The factories that produce these materials are not only manufacturing hubs but also centers of innovation and quality assurance. As industries continue to evolve, the demand for high-quality wire mesh products will likely grow, driving advancements in production techniques and materials science. The world of stainless steel wire mesh is indeed a remarkable and integral part of modern manufacturing and construction.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025