-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 19, 2024 06:39 Back to list

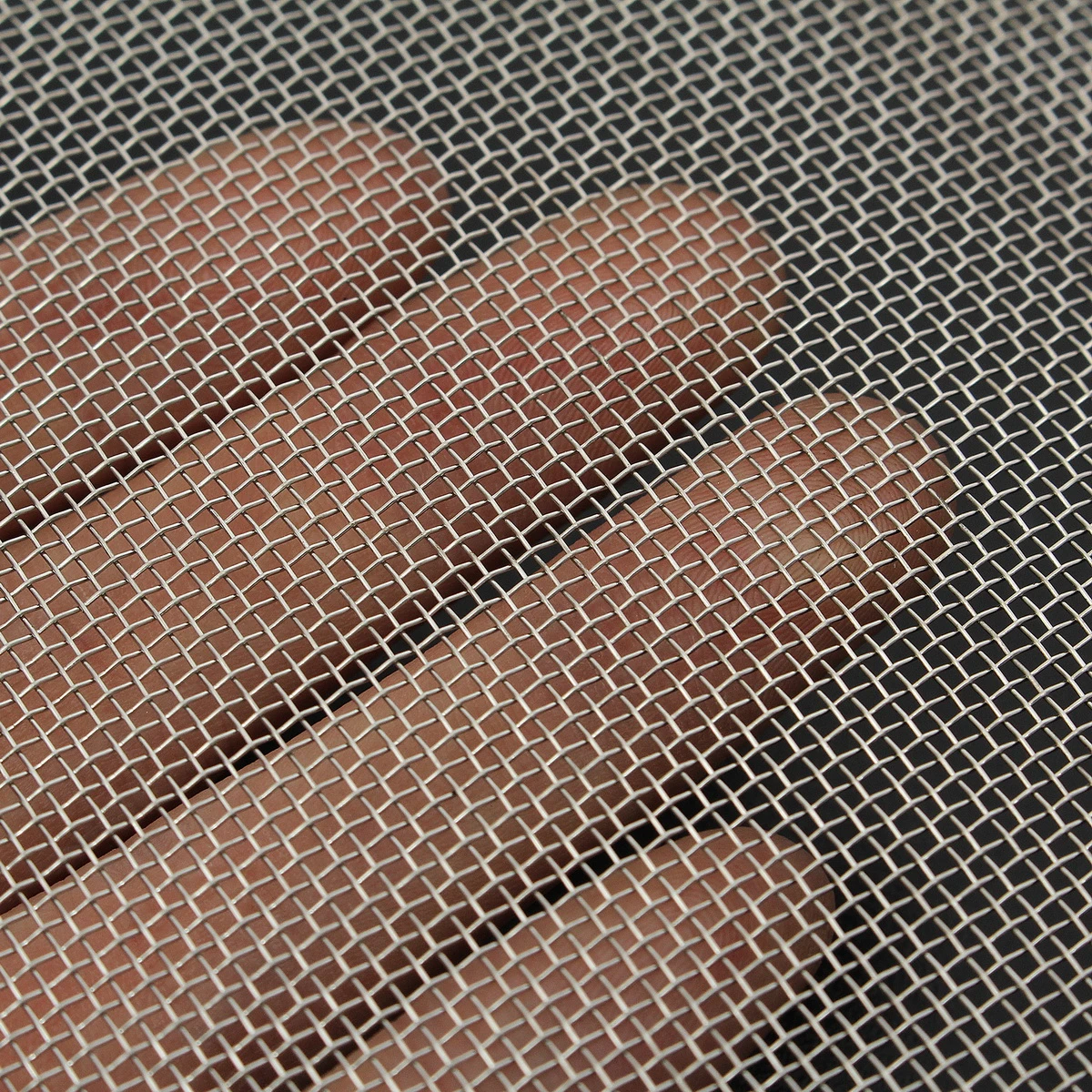

high quality perforated metal mesh sheet

High-Quality Perforated Metal Mesh Sheets An Overview

In various industries, the demand for versatile materials has led to the increasing popularity of perforated metal mesh sheets. These sheets, made from various metals such as steel, aluminum, and brass, feature a series of holes or openings that provide unique functionalities while maintaining a lightweight and durable structure. This article delves into the characteristics, advantages, and applications of high-quality perforated metal mesh sheets.

Understanding Perforated Metal Mesh

Perforated metal mesh sheets are created by punching holes in a preformed sheet of metal, resulting in patterns that can be customized according to specific requirements. The perforations can vary in size, shape, and arrangement, leading to a wide range of aesthetic and functional characteristics. The quality of the perforated sheet is often determined by the precision of the holes, the integrity of the metal used, and the finishing process it undergoes.

Key Characteristics

1. Materials Used High-quality perforated metal mesh sheets are typically made from materials like stainless steel, mild steel, aluminum, and copper. Each material offers distinct benefits, such as corrosion resistance, strength, and weight.

2. Durability One of the prime advantages of using perforated metal is its exceptional durability. The robust nature of the metal means it can withstand harsh environmental conditions, making it suitable for both indoor and outdoor applications.

3. Customizability Manufacturers of perforated metal sheets can customize dimensions, hole sizes, and patterns to meet specific client needs. This level of customization allows for the product to be tailored for various applications, from aesthetic features in architecture to functional uses in industrial settings.

4. Aesthetic Appeal Beyond functionality, perforated metal sheets can serve as striking architectural elements. They are often used in facades, partitions, and decorative installations, providing an aesthetic flair while also allowing natural light and airflow.

Advantages of High-Quality Perforated Metal Mesh

1. Ventilation and Light Transmission The open design of perforated metal sheets facilitates airflow and natural light transmission, making them ideal for applications where ventilation is crucial.

high quality perforated metal mesh sheet

2. Weight Reduction Due to their perforated nature, these sheets are significantly lighter than solid metal sheets while maintaining necessary strength and rigidity. This weight reduction is beneficial for construction and fabrication, where minimizing load is essential.

3. Noise Reduction Perforated metal can help in reducing noise levels in busy environments. The holes in the sheets can absorb sound waves, making them a practical option for acoustical applications.

4. Ease of Maintenance High-quality perforated metal sheets are relatively easy to clean and maintain, especially when coated with protective finishes. This makes them ideal for environments that require regular sanitation, such as food processing and medical facilities.

Applications

The versatility of high-quality perforated metal mesh sheets allows them to be used across various industries, including

- Construction and Architecture Often used for facades, sunshades, and interior design elements, enhancing both functionality and aesthetics. - Manufacturing and Industrial Ideal for filters, sieves, and screens, they serve critical roles in ensuring product quality and operational efficiency.

- Automotive Utilized in vehicle components, including grilles and sound dampening elements, that benefit from both lightweight and sturdy materials.

- Furniture Design Increasingly popular in modern furniture design, perforated sheets are used to create innovative designs in tables, chairs, and decorative screens.

Conclusion

High-quality perforated metal mesh sheets represent a perfect blend of functionality and aesthetic value. Their customizable nature, combined with durability and ease of maintenance, makes them an excellent choice across multiple industries. Whether for construction, manufacturing, or design, investing in quality perforated sheets can significantly enhance the performance and appearance of projects. As industries continue to evolve, the applications of these versatile sheets are likely to expand, making them a staple in modern material usage.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025