-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 03, 2024 09:18 Back to list

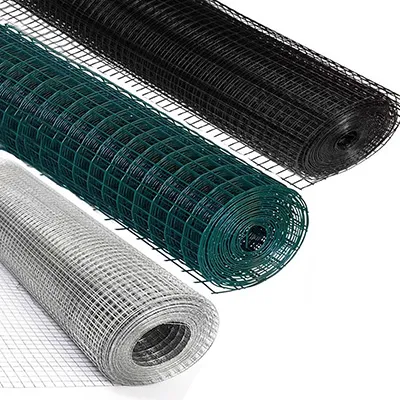

Top Quality Wire Mesh Products from Leading Manufacturer in the Industry

The Versatility of Wire Mesh A Deep Dive into Manufacturing and Applications

Wire mesh is an essential component in various industries, serving multiple purposes due to its versatile nature. As a product manufactured from a variety of materials such as stainless steel, aluminum, and galvanized iron, wire mesh can be found in everything from construction and architecture to agriculture and industrial applications. In this article, we will explore the manufacturing processes involved in producing wire mesh and its wide-ranging applications, showcasing why wire mesh manufacturers play a vital role in multiple sectors.

Understanding Wire Mesh Manufacturing

The manufacturing of wire mesh typically involves several key processes that ensure the product meets specific requirements for strength, durability, and functionality. The first step in manufacturing wire mesh is evaluating the intended use of the final product. This evaluation determines the type of material, wire diameter, and mesh size required.

The materials used are often selected based on the environment in which the wire mesh will be utilized. For example, stainless steel is commonly chosen for marine applications due to its corrosion resistance, while galvanized wire is a more economical option for outdoor use where rusting is a concern.

Once the material selection is made, the production process commences. Wire is drawn into various diameters, and the chosen wire is cut to length before being woven into mesh. There are several weaving techniques, including plain weave, twill weave, and Dutch weave, each producing a distinct mesh pattern suitable for different applications. The weaving process is critical, as it influences the mesh's tensile strength, flexibility, and overall performance.

After weaving, the wire mesh undergoes various finishing processes, such as coating, galvanizing, or anodizing, to enhance durability and resistance to environmental factors. Quality control checks are essential throughout the production process to ensure that every roll of wire mesh meets the specified tolerances.

Applications of Wire Mesh

wire mesh manufacturer

Wire mesh is used in numerous applications across different industries, highlighting its importance. Here are some key areas where wire mesh has proven to be invaluable

1. Construction and Architecture In the construction industry, wire mesh is often utilized as reinforcement in concrete structures, providing increased tensile strength to concrete foundations, walls, and pavements. Its lightweight and resilient nature also make it ideal for architectural designs, including partitions and decorative facades.

2. Industrial Uses Manufacturing sectors utilize wire mesh for screening and filtration processes, ensuring that unwanted particles do not contaminate products. It can be found in various equipment such as sieves, filters, and conveyors, playing a crucial role in maintaining product integrity.

3. Agriculture Farmers often use wire mesh for fencing purposes to protect crops from wildlife. Additionally, it is employed for creating livestock enclosures and animal pens, providing security while allowing for adequate airflow.

4. Home and Garden Wire mesh serves several practical purposes in residential settings, from creating compost bins and plant supports to providing security for gardens. It can also be effectively used in decorative applications, such as trellises and garden screens.

5. Automotive and Aerospace In these industries, wire mesh is utilized in applications ranging from air and fluid filters to protective guards and screens, ensuring functionality while maintaining safety standards.

Conclusion

The importance of wire mesh manufacturers cannot be overstated as they produce essential materials that serve countless industries and applications. The manufacturing process, from material selection to the final product, demonstrates a commitment to quality and dependability, which ultimately enhances the performance of various applications. As industries continue to evolve and innovate, the demand for specialized wire mesh solutions will undoubtedly grow, positioning wire mesh manufacturers at the forefront of industrial development and progress.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025