-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Kas . 30, 2024 21:31 Back to list

black brick welded mesh factories

The Robust World of Black Brick Welded Mesh Factories

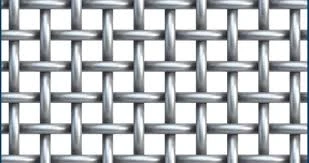

In the realm of construction and industrial applications, black brick welded mesh has emerged as a pivotal material due to its strength, versatility, and cost-effectiveness. As urbanization accelerates and infrastructure projects gain momentum, the significance of specialized manufacturing facilities, particularly black brick welded mesh factories, cannot be overstated. This article delves into the workings, advantages, and industry implications of black brick welded mesh factories.

Understanding Black Brick Welded Mesh

Black brick welded mesh is characterized by its distinctive appearance, a combination of black wire and square or rectangular openings. This mesh is typically made from high-quality black annealed wire, ensuring excellent resistance to corrosion and enhancing the durability of constructions. It is widely used in various applications, from reinforcement in concrete structures to fencing and partitioning.

The manufacturing process of black brick welded mesh involves the precise welding of intersecting wires using advanced machinery, ensuring a robust final product. This method offers multiple benefits, including enhanced strength and uniformity, which are crucial in maintaining structural integrity in construction projects.

The Manufacturing Process

The journey of creating black brick welded mesh begins with the selection of raw materials. High-quality steel wire is chosen for its tensile strength and durability. In the factories, the manufacturing process typically follows these steps

1. Wire Drawing The raw steel is drawn into wires of specific diameters, depending on the design requirements.

2. Welding The wires are then arranged in a grid pattern and welded together at intersections. This is the most critical phase, as it determines the mesh's strength and resistance to tearing.

3. Coating After welding, the meshes may undergo additional treatment, such as galvanization or coating, to enhance their resistance to rust and other environmental factors.

These processes highlight the technological advancements in welded mesh production, ensuring high-quality outputs that meet industry standards.

black brick welded mesh factories

Advantages of Black Brick Welded Mesh

The use of black brick welded mesh in construction offers several advantages

- Strength and Durability The welded nature of the mesh provides excellent tensile strength, making it suitable for reinforcing concrete and masonry.

- Cost-Effective Compared to alternative solutions, black brick welded mesh is often more affordable while delivering comparable performance.

- Versatility This mesh can be used in a variety of applications, from industrial construction to agricultural fencing, showcasing its adaptability.

- Ease of Installation Contractors favor black brick welded mesh due to its lightweight nature and straightforward installation process, significantly reducing labor time and costs.

Industry Implications

The growth of black brick welded mesh factories reflects a broader trend towards modernization and efficiency in manufacturing. As the demand for construction materials rises, these factories are becoming more automated and integrated, reducing production times and enhancing quality control.

Furthermore, the emphasis on sustainability is changing the landscape of welded mesh production. Many factories are adopting eco-friendly practices, utilizing recycled materials and minimizing waste during manufacturing. This shift not only meets regulatory requirements but also appeals to environmentally conscious consumers and builders.

Conclusion

As cities expand and infrastructure needs evolve, the role of black brick welded mesh factories becomes increasingly vital. These factories are instrumental in providing strong, durable, and cost-effective materials essential for modern construction. With ongoing technological advancements and a growing focus on sustainability, the future of black brick welded mesh production looks promising. The industry is poised to play a significant role in shaping the landscapes of our cities, ensuring safety, strength, and aesthetic appeal in construction projects worldwide.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025