-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Ara . 05, 2024 15:26 Back to list

custom hot dip galvanized wire

Custom Hot Dip Galvanized Wire A Comprehensive Overview

In today's industrial landscape, the demand for durable and corrosion-resistant materials continues to rise, and hot dip galvanized wire has emerged as an excellent solution. This specialized wire is treated with a coating of zinc through a process known as hot dip galvanization, which significantly enhances its longevity and resistance to harsh environmental conditions. In this article, we will delve into the properties, applications, and benefits of custom hot dip galvanized wire, highlighting its significance across various industries.

What is Hot Dip Galvanization?

Hot dip galvanization is a process where steel or iron is immersed in a molten bath of zinc at a temperature of approximately 450 degrees Celsius. This forms a metallurgically bonded zinc coating on the surface of the metal, providing a barrier that protects the underlying material from corrosion and rust. Unlike other coating methods, such as electro-galvanization, the hot dip method offers a thicker and more durable layer, ensuring long-lasting protection.

Properties of Custom Hot Dip Galvanized Wire

The properties of custom hot dip galvanized wire make it an outstanding choice for various applications. Primarily, its exceptional corrosion resistance allows it to withstand the effects of moisture, chemicals, and environmental stressors. This is particularly important in outdoor applications where wires are exposed to the elements.

Additionally, hot dip galvanized wires boast high tensile strength, making them ideal for use in demanding applications requiring stability and durability. The zinc coating also provides a level of flexibility, allowing the wire to bend and stretch without breaking, which is crucial in construction and fencing applications.

Applications

Custom hot dip galvanized wire is versatile and widely utilized across numerous industries. Some common applications include

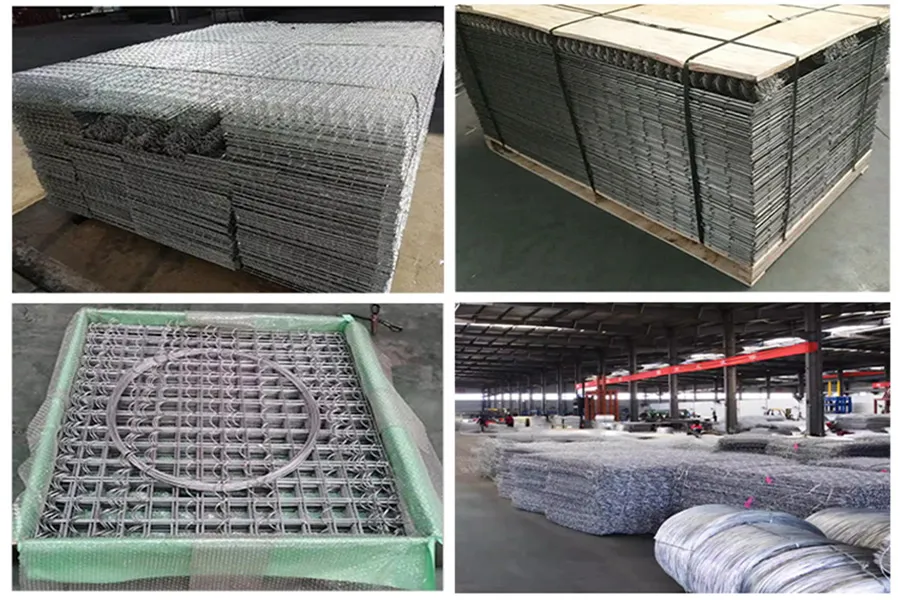

1. Construction In the construction sector, this galvanized wire is extensively used for reinforcing concrete, creating wire mesh, and for binding materials together. Its strength and corrosion resistance make it indispensable for both commercial and residential projects.

custom hot dip galvanized wire

3. Electrical In electrical installations, hot dip galvanized wire is often employed for grounding applications, ensuring effective conductivity while providing protection against corrosion.

4. Manufacturing Various manufacturing processes utilize hot dip galvanized wire for producing high-quality products, ensuring their longevity and performance in the market.

5. Aerospace and Automotive The aerospace and automotive industries increasingly recognize the benefits of using galvanized wire for components that require both strength and resistance to environmental factors.

Benefits of Custom Solutions

The ability to customize hot dip galvanized wire offers significant advantages. Industries can specify wire diameter, tensile strength, and other properties tailored to their specific needs. Custom solutions enable businesses to optimize their operations, improving efficiency and reducing costs over time.

Moreover, such customization ensures that the wire performs optimally in its intended application environment. It allows companies to address specific challenges they face, employing a product that perfectly aligns with their operational requirements.

Conclusion

In conclusion, custom hot dip galvanized wire represents a crucial advancement in materials engineering, providing unparalleled durability, corrosion resistance, and versatility. As industries continue to evolve and face new challenges, the importance of robust and reliable materials like hot dip galvanized wire cannot be overstated. Whether in construction, agriculture, electrical, or manufacturing, the benefits of this specialized wire are vast, making it an essential choice for businesses looking to enhance their product offerings and operational effectiveness. As demand grows, the emphasis on quality and customization will continue to shape the market for hot dip galvanized wire, ensuring its place as a trusted material for the future.

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025