-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Kas . 22, 2024 22:32 Back to list

fencing wire with pole manufacturer

Fencing Wire with Pole Manufacturer Ensuring Quality and Durability

Fencing is an essential aspect of property management, agriculture, and security. It not only defines boundaries but also provides safety for livestock, crops, and residential areas. As the demand for reliable and durable fencing solutions grows, the role of fencing wire with pole manufacturers becomes increasingly crucial. This article explores the various dimensions of fencing wire and pole manufacturing, emphasizing their importance in quality assurance, material selection, and technological advancements.

Understanding Fencing Wire and Poles

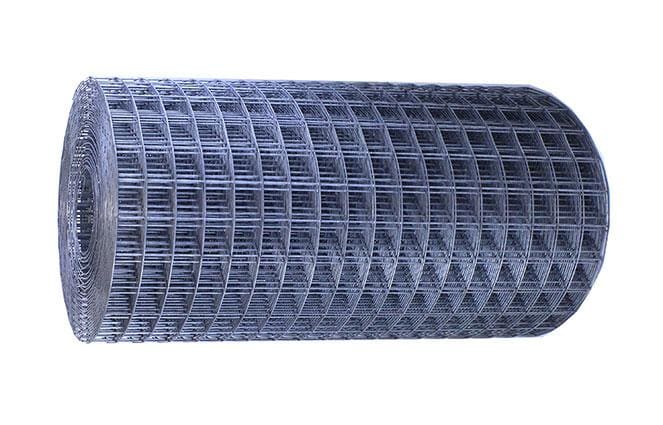

Fencing wire is a key component of any fencing system, providing the structure and strength required to secure a designated area. It comes in various styles and materials, including galvanized wire, barbed wire, and electric fencing options. On the other hand, poles provide the necessary support and height to the fencing system. They can be made from wood, metal, or composite materials, with each offering unique advantages.

The Importance of Quality Manufacturing

When selecting a manufacturer for fencing wire and poles, quality is paramount. Poorly manufactured wire can lead to rusting, snapping, or sagging over time, compromising the entire fencing system. High-quality manufacturers use high-grade materials and adhere to strict manufacturing processes to ensure longevity and resilience.

One of the key indicators of a reliable manufacturer is their commitment to industry standards. A good manufacturer will comply with local and international quality certifications, such as ISO standards, ensuring that their products undergo rigorous testing and evaluation. This commitment to quality not only guarantees durability but also instills confidence in consumers.

Material Selection

fencing wire with pole manufacturer

The choice of materials used in fencing wire and poles is critical. Galvanized steel, for example, is one of the most popular choices for fencing wire due to its resistance to rust and corrosion. This makes it ideal for outdoor use, where exposure to the elements can degrade weaker materials. Furthermore, manufacturers are increasingly exploring advanced materials like high-tensile wire, which offers greater strength with less weight.

When it comes to poles, the selection often depends on the application. Wooden poles are aesthetically pleasing and provide good support for lighter fencing solutions, while metal poles are favored for heavy-duty applications and offer superior durability. Composite materials are also gaining popularity, providing a balance between weight and strength, and are often treated to resist rot and insect infestation.

Technological Advancements in Manufacturing

In today’s market, technological advancements play a pivotal role in the manufacturing of fencing wire and poles. Automated machinery and innovative techniques allow manufacturers to produce more consistent and high-quality products at a lower cost. The use of computer-aided design (CAD) systems enables custom solutions tailored to specific customer needs.

Additionally, advancements in coating technologies, such as powder coating and vinyl coatings, enhance the longevity and appearance of fencing products. These coatings provide extra protection against environmental factors, thereby extending the life of the fencing system.

Conclusion

Selecting the right fencing wire and pole manufacturer is an essential decision that can significantly impact the effectiveness and durability of a fencing system. By prioritizing quality, material selection, and technological innovation, manufacturers are ensuring that their products meet the evolving needs of consumers. As the industry continues to grow, investing in high-quality fencing solutions will not only provide peace of mind but will also stand the test of time, safeguarding properties and livelihoods for years to come.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025