-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Ağu . 17, 2024 19:33 Back to list

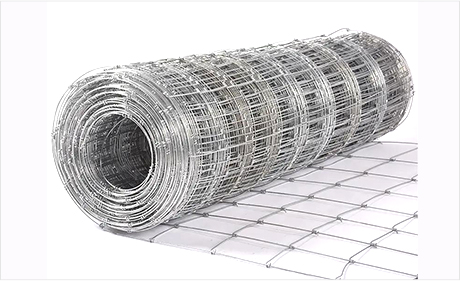

Leading Manufacturers of Crimped Woven Mesh for Industrial Applications and Custom Solutions

Understanding Crimped Woven Mesh Manufacturers

Crimped woven mesh has become an indispensable material in various industries, ranging from construction to agriculture, due to its unique structural properties and versatile applications. This type of mesh is created by interweaving wire strands that have been crimped, giving it enhanced strength and stability. As demand for crimped woven mesh continues to grow, understanding the role of manufacturers in this sector is essential.

What is Crimped Woven Mesh?

Crimped woven mesh is fabricated by weaving wires that have been intentionally crimped to create a textured surface. The crimping process involves bending the wire into a series of waves or undulations, which increases the material's tensile strength and flexibility. This technique also allows manufacturers to create mesh with varying degrees of openness and thickness, tailored to meet specific requirements. The weaving process can produce different patterns, such as square or rectangular meshes, depending on the intended use.

Applications of Crimped Woven Mesh

Crimped woven mesh has a wide range of applications across industries

1. Construction and Architecture It is used as a reinforcement material in concrete, providing additional strength to structures. Additionally, it is often utilized for façade panels, offering both aesthetic appeal and functional benefits.

2. Filtration This mesh is popular in filtration systems, such as those found in water treatment plants and industrial applications. Its varied opening sizes allow for precise filtration, making it suitable for separating different materials or particles.

3. Agriculture In the agricultural sector, crimped woven mesh is used for fencing, animal enclosures, and as protective screens. It helps in managing livestock and preventing wild animals from entering crop fields.

crimped woven mesh manufacturers

Selecting a Reliable Manufacturer

When it comes to sourcing crimped woven mesh, selecting a reliable manufacturer is critical. Here are several factors to consider

- Quality Assurance The manufacturer should adhere to strict quality standards, ensuring that their products are durable and reliable. Look for certifications or compliance with industry standards.

- Customization Options Different applications may require specific mesh sizes, wire gauges, and crimping styles. A good manufacturer should offer customization to meet unique project needs.

- Material Sourcing The quality of raw materials plays a significant role in the performance of crimped woven mesh. Manufacturers that source high-grade materials will produce a superior product.

- Experience and Reputation Established manufacturers with a proven track record are often more reliable than newer companies. Researching customer reviews and testimonials can provide insights into their reputation.

- Customer Support A responsive customer service team is essential for addressing any queries or concerns during the purchasing process. Good communication enhances the overall buying experience.

Conclusion

Crimped woven mesh manufacturers play a vital role in supplying this versatile material for various applications. As industries continue to evolve, the demand for crimped woven mesh is likely to increase, emphasizing the need for manufacturers to innovate and maintain high standards. Understanding the characteristics, applications, and processes involved in sourcing crimped woven mesh can help consumers make informed decisions, ultimately leading to more effective and economical use of this valuable resource. By collaborating with reputable manufacturers, industries can ensure they receive high-quality products that meet their specific needs, fostering sustainable growth in their respective sectors.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025