-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Kas . 09, 2024 20:45 Back to list

Understanding the Applications and Benefits of Perforated Sheet Metal in Various Industries

Understanding Perforated Sheet Metal Applications, Benefits, and Design Considerations

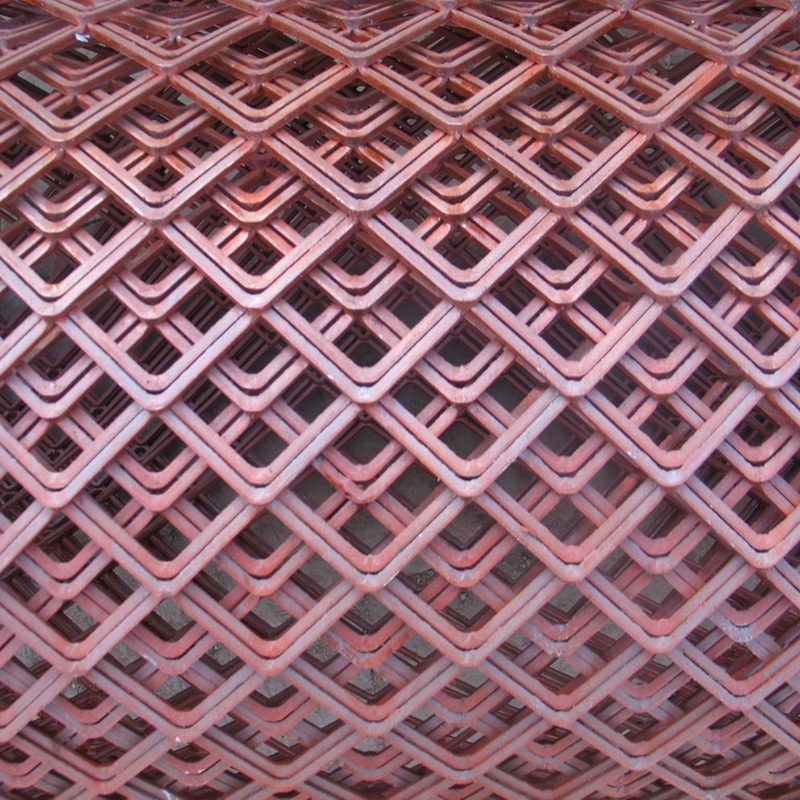

Perforated sheet metal is a versatile material used extensively across various industries due to its unique combination of physical properties and aesthetic appeal. The process involves creating a pattern of holes in sheets of metal, which can range from small pinholes to larger openings depending on the required application. This article will explore the applications, benefits, design considerations, and manufacturing processes associated with perforated sheet metal.

Applications

Perforated sheet metal finds use in multiple sectors, including construction, automotive, aerospace, filtration, and decorative arts. In construction, it is commonly used for facades and ceilings, as it allows for light and sound penetration while maintaining structural integrity. For example, architects favor perforated metals due to their ability to create striking visual impressions while enhancing air circulation and natural lighting in building designs.

In the automotive industry, perforated sheet metal is often used for components that need to be lightweight yet strong. It aids in cooling systems by allowing airflow while also serving as an effective weight-reduction strategy. Aerospace applications similarly benefit from the lightweight nature of perforated metals, contributing to overall fuel efficiency and performance.

The filtration industry utilizes perforated sheet metal for creating filters and separators that ensure the efficient flow of liquids or gases while excluding unwanted materials. By controlling the size and arrangement of the perforations, manufacturers can design products tailored to specific filtration needs.

Furthermore, perforated sheet metal finds its place in the decorative arts, being used for architectural elements, screens, and art installations

. Its ability to create intricate designs while maintaining functionality makes it a favored choice among designers.Benefits

The advantages of using perforated sheet metal are numerous. First and foremost, the lightweight nature of the material allows for easier handling and installation, making it suitable for a wide variety of applications. Additionally, the perforation process can enhance the strength of the metal sheet without significantly increasing its weight.

perforated sheet metal

Another significant benefit is the improved airflow and drainage capabilities provided by the holes. This characteristic can be critical in industries such as construction and automotive, where effective ventilation can prevent overheating and ensure optimal performance.

Moreover, the aesthetic appeal of perforated sheet metal cannot be overlooked. With a variety of hole patterns, sizes, and finishes available, it offers limitless design possibilities. Customization can give a unique touch to both functional and decorative projects, allowing architects and designers to express creativity while adhering to practical requirements.

Design Considerations

When designing with perforated sheet metal, several factors must be taken into account to achieve the desired outcome. The size and pattern of holes are crucial, as they influence the material's strength, weight, and functionality. Larger holes might reduce weight and material costs but could compromise strength, while smaller holes often provide better control over air and liquid flow.

The type of metal is another vital consideration. Common materials include stainless steel, aluminum, and copper, each bringing distinct properties, such as corrosion resistance or malleability. The selection depends largely on the application's environment and requirements.

Additionally, it is essential to consider the thickness of the sheet metal. Thicker sheets tend to be sturdier but can be heavier and less flexible, while thinner sheets allow for greater ease of fabrication but may require careful handling to maintain their structural integrity.

Lastly, factors such as manufacturing processes, lead times, and costs should also be factored into the design phase. Engaging with reputable manufacturers who specialize in perforated metal can provide insights and solutions that align with the project’s needs.

Conclusion

Perforated sheet metal is an invaluable resource in modern applications, balancing functional requirements with aesthetic qualities. Its uses span a vast range of industries, making it a go-to option for engineers, architects, and designers alike. Understanding the benefits, applications, and design considerations is crucial in harnessing the full potential of this remarkable material. Whether for structural elements, decorative features, or functional components, perforated sheet metal continues to shape the future of design and engineering.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025