-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Eki . 10, 2024 21:21 Back to list

square wire panel 4x4 factories

Exploring Square Wire Panel 4x4 Factories A Comprehensive Overview

In today's fast-paced industrial world, the demand for high-quality materials is ever-increasing. One such material that has garnered significant attention is the square wire panel, particularly the 4x4 variant. These panels are versatile and are used in various applications, from agricultural to construction and even in decorative elements. As industries evolve, so do the factories that manufacture these essential components. Understanding the square wire panel 4x4 factories helps us appreciate their contribution to the economy and the innovation driving this sector.

What is a Square Wire Panel?

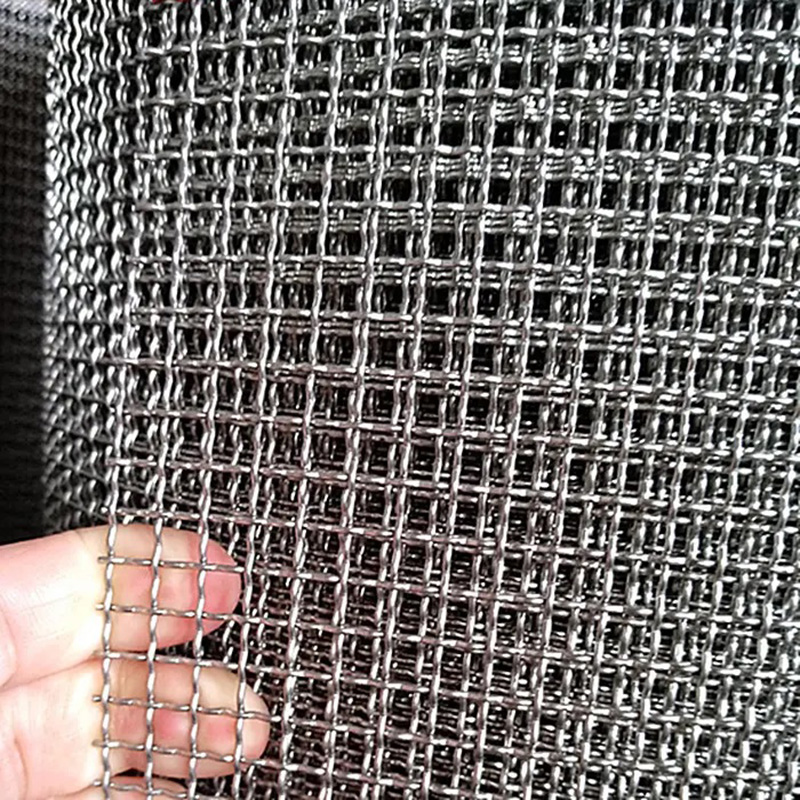

A square wire panel typically consists of a grid of wires arranged in a square formation. The 4x4 designation refers to the dimensions of the panel, which has four inches between the wires both horizontally and vertically. This specific panel size is favored for its balance of structural integrity and flexibility. It allows for excellent visibility while providing secure containment, making it ideal for various purposes such as fencing, animal enclosures, and construction support.

The Manufacturing Process

The manufacturing process of square wire panels involves several steps, starting from raw material selection to final product testing. Factories specializing in 4x4 square wire panels often source high-quality steel wires, which are then processed in a controlled environment.

1. Wire Production First, raw steel rods are drawn into thin wires using a series of dies. The diameter of these wires can vary depending on the final application.

2. Welding After the wires are produced, they are cut to the desired length. The next step involves welding the wires into a grid formation. Automated welding machines are often used to ensure precision and consistency across panels.

4. Quality Control Before packaging, the panels are subjected to stringent quality control processes. This includes checking for weld integrity, dimensional accuracy, and surface finish. Factories often employ advanced technology to conduct these tests, ensuring that only the highest-quality products reach the market.

square wire panel 4x4 factories

Types of Square Wire Panels

Square wire panels come in various types, tailored to specific applications. Here are some of the most common

- Galvanized Steel Panels These panels are coated with zinc, offering superior resistance to corrosion. They are ideal for outdoor use, particularly in fencing for farms and gardens.

- Welded Wire Panels Characterized by their strong and stable structure, these panels are commonly used in construction for safety barriers and reinforcement.

- Decorative Panels Made in a variety of designs and finishes, these panels are used in landscaping and architectural applications. They provide both functionality and aesthetic appeal.

Market Demand and Trends

The demand for square wire panels, especially the 4x4 variety, has been on the rise due to several factors. Urbanization and the need for secure fencing solutions in residential and commercial properties have driven this growth. Additionally, with the agricultural sector constantly evolving, farmers seek reliable fencing and containment solutions for livestock and crops.

Sustainability is another important trend impacting square wire panel manufacturing. Many factories are adopting eco-friendly practices, such as recycling scrap materials and reducing energy consumption during production. Consumers are becoming increasingly aware of the environmental footprint of their purchases, leading to a preference for products that align with sustainable practices.

Conclusion

The square wire panel 4x4 factories play a crucial role in various industries, providing essential products that cater to a wide range of applications. Through advanced manufacturing processes and a commitment to quality, these factories continue to innovate, ensuring they meet the evolving needs of their customers. As industries pursue sustainability and efficiency, the future of square wire panels looks promising, contributing not only to economic growth but also to environmental stewardship. Understanding the dynamics of these factories gives us insight into the backbone of industrial supply chains that keep our world connected and secure.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025