-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oca . 09, 2025 11:56 Back to list

Welded Wire Mesh

Welded wire mesh is a versatile and highly reliable material extensively used in construction and industrial applications. Its robustness and flexibility make it an essential component for various projects, ranging from fencing to concrete reinforcement. Drawing from years of experience in construction and materials science, professionals often rely on welded wire mesh for its unmatched durability and adaptability.

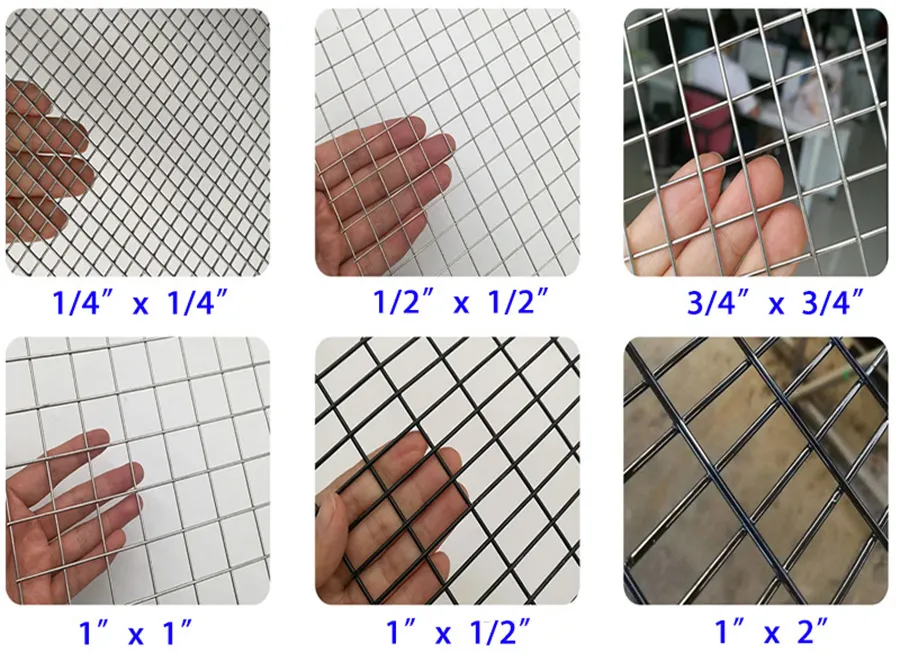

The versatility of welded wire mesh extends to customization options, catering to unique project requirements. Available in various gauges, sizes, and finishes, it allows architects and engineers to select the most suitable configuration to meet specific demands. This adaptability underlines the authoritative nature of welded wire mesh in problem-solving within diverse industrial scenarios. Furthermore, coated meshes are resistant to corrosion, making them particularly valuable for projects exposed to harsh environmental conditions. Trust in welded wire mesh is reinforced by its consistent performance record over the years. Industry leaders recognize its value, often recommending it for projects where safety and reliability are paramount. It’s crucial to ensure that the mesh utilized is sourced from reputable manufacturers that adhere to international quality standards. This practice not only guarantees the product's performance but also aligns with sustainable development goals by selecting materials with lesser environmental footprints and high recyclability. In summary, welded wire mesh stands out as a material of choice for professionals seeking solutions that combine strength, adaptability, and cost-efficiency. Its consistent use across various industries testifies to its trustworthiness and the critical role it plays in modern construction and industrial processes. Emphasizing authentic experiences and proven expertise, welded wire mesh continues to be an authoritative and reliable choice for stakeholders aiming to achieve superior project outcomes.

The versatility of welded wire mesh extends to customization options, catering to unique project requirements. Available in various gauges, sizes, and finishes, it allows architects and engineers to select the most suitable configuration to meet specific demands. This adaptability underlines the authoritative nature of welded wire mesh in problem-solving within diverse industrial scenarios. Furthermore, coated meshes are resistant to corrosion, making them particularly valuable for projects exposed to harsh environmental conditions. Trust in welded wire mesh is reinforced by its consistent performance record over the years. Industry leaders recognize its value, often recommending it for projects where safety and reliability are paramount. It’s crucial to ensure that the mesh utilized is sourced from reputable manufacturers that adhere to international quality standards. This practice not only guarantees the product's performance but also aligns with sustainable development goals by selecting materials with lesser environmental footprints and high recyclability. In summary, welded wire mesh stands out as a material of choice for professionals seeking solutions that combine strength, adaptability, and cost-efficiency. Its consistent use across various industries testifies to its trustworthiness and the critical role it plays in modern construction and industrial processes. Emphasizing authentic experiences and proven expertise, welded wire mesh continues to be an authoritative and reliable choice for stakeholders aiming to achieve superior project outcomes.

Next:

Latest news

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025