-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Ara . 12, 2024 11:44 Back to list

wire mesh cages factory

The Versatile World of Wire Mesh Cages A Comprehensive Overview of Factories and Their Production

Wire mesh cages serve as essential components across multiple industries, ranging from agriculture to manufacturing. Their versatility comes from being custom-made to suit various applications, ensuring both functionality and durability. This article delves into the intricacies of wire mesh cage factories, their manufacturing processes, and the diverse types of cages produced for different uses.

Understanding Wire Mesh Cages

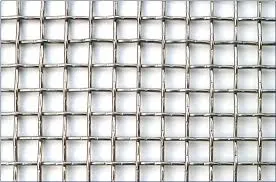

Wire mesh cages are structures made from thin strands of wire woven together to create a grid-like pattern. These cages can take on various forms, depending on their intended use, and can be constructed from materials such as stainless steel, galvanized iron, and coated wire. The demand for wire mesh cages spans several sectors, including farming, pet enclosures, storage solutions, and even industrial applications.

Key Applications of Wire Mesh Cages

1. Agricultural Use In agriculture, wire mesh cages are widely utilized for raising small animals or birds, offering a secure environment while allowing for ventilation and visibility. For instance, poultry farmers often use these cages to house chickens, ensuring their safety while providing ease of access for feeding, cleaning, and monitoring health.

2. Pet Enclosures For pet owners, wire mesh cages provide a safe haven for pets like rabbits, guinea pigs, and other small animals. These cages are designed to prevent escapes while offering plenty of ventilation and space to move around. They can be custom-designed to suit specific pet needs and fit within the available space at home.

3. Storage Solutions In industrial and commercial settings, wire mesh cages are utilized for secure storage. These cages are often employed to hold tools, equipment, or even materials in warehouses, ensuring that items are organized, easily accessible, and protected from theft or damage. The transparent design of the mesh allows for easy inventory checks.

4. Aquaculture Wire mesh cages also play a crucial role in aquaculture, where they are used to raise fish in controlled environments. The design ensures proper water circulation and has become a popular choice for fish farms looking to optimize space and manage their stock efficiently.

wire mesh cages factory

The Manufacturing Process

The production of wire mesh cages typically follows a systematic manufacturing process that includes several key stages

1. Material Selection The choice of material is paramount and is often determined by the intended application. Stainless steel is favored for its corrosion resistance, while galvanized iron is popular for its strength and affordability.

2. Wire Drawing Once the materials are selected, wire drawing begins, where large coils of metal are pulled through a series of dies to create strands of the desired thickness. The gauge of the wire affects the overall strength and durability of the finished product.

3. Weaving In the weaving stage, the drawn wire is interlaced to form the mesh. This can be done through various methods, including welded or woven techniques. The choice of method can affect the flexibility and overall stability of the cage structure.

4. Finishing Touches Post-weaving, the mesh may undergo additional treatments, such as galvanizing or coating, to enhance its protective features and longevity. This ensures that the cage can withstand exposure to the elements, particularly in outdoor settings.

5. Assembly Finally, the individual mesh panels are cut, shaped, and assembled into the final product. This may include adding reinforced edges, doors, or lock mechanisms, depending on customer specifications.

Conclusion

Wire mesh cage factories play a pivotal role in supplying various industries with essential products designed for safety, efficiency, and functionality. As demand continues to grow across different sectors, innovations in materials and manufacturing processes signify a bright future for wire mesh cages. Their adaptability and reliability ensure that they will remain integral to agricultural practices, pet care, storage solutions, and beyond. Understanding the complexities behind the production of wire mesh cages allows consumers to appreciate the craftsmanship and engineering that go into creating these versatile structures.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025