-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Лис . 16, 2024 06:17 Back to list

concrete wire mesh roll factory

The Importance of Concrete Wire Mesh Roll in Construction A Look into the Factory Production

Concrete wire mesh rolls are a fundamental component in the construction industry, providing stability and strength to various structures. As urbanization continues to surge, the demand for strong and durable materials has never been higher. Factories producing concrete wire mesh rolls play a critical role in meeting this demand, ensuring that builders have access to high-quality reinforcing solutions that enhance the integrity of concrete structures.

What is Concrete Wire Mesh?

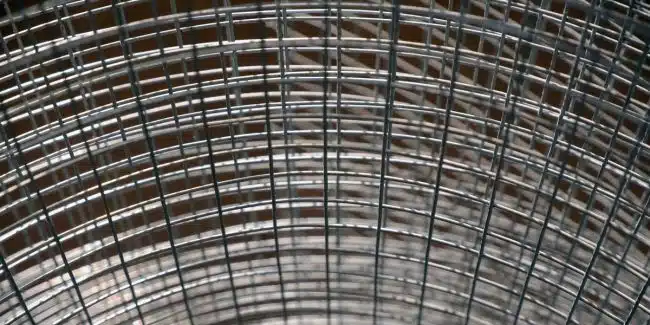

Concrete wire mesh is a grid-like structure made of steel wires that are interwoven to form a robust lattice. This mesh is typically used to reinforce concrete slabs, sidewalks, driveways, and other surfaces requiring an additional layer of strength. By distributing weight and stress evenly, wire mesh helps to minimize the likelihood of cracks and improves the overall durability of concrete installations.

The Manufacturing Process

The production of concrete wire mesh rolls involves several steps to ensure high-quality output. Factories start with the selection of raw materials, primarily high-grade steel wires. The thickness and gauge of these wires can vary based on the specific requirements of the construction project.

1. Wire Preparation The manufacturing process begins with the preparation of steel wires. These wires are drawn to the desired thickness and coated, if necessary, to enhance their corrosion resistance. Galvanization is a common treatment that protects the mesh from rust and extends its lifespan.

2. Mesh Weaving The prepared wires are then woven together to create the mesh. This process typically involves using automated machinery that precisely intersects the wires at equal intervals. The resulting mesh can vary in size and shape – from small, tightly woven patterns for residential projects to larger, looser meshes for industrial applications.

3. Quality Control Once the mesh is manufactured, it undergoes rigorous quality checks. This ensures that the product meets the specifications required for different construction needs. Factors such as tensile strength, dimensions, and corrosion resistance are assessed to ascertain the product's reliability.

concrete wire mesh roll factory

4. Rolling and Packaging After passing quality control, the mesh is rolled into convenient sizes for shipping and storage. Packaging is designed to protect the mesh during transportation, ensuring it arrives at construction sites in prime condition.

Applications of Concrete Wire Mesh

Concrete wire mesh rolls are versatile and can be used across a variety of construction projects. Some common applications include

- Floor Systems Wire mesh is often used in concrete floors, providing essential tensile support to control cracking due to thermal expansion and contraction. - Roads and Bridges It enhances the durability of pavement and is critical in the construction of highways and bridges where heavy loads are substantial. - Retaining Walls In retaining walls, wire mesh helps distribute pressure exerted by soil, ensuring the wall remains stable and serviceable. - Residential Projects Home foundations, driveways, and patios benefit from the added strength provided by wire mesh, minimizing maintenance costs over time.

Future Trends in Concrete Wire Mesh Production

As the construction industry evolves, so does the technology behind concrete wire mesh production. Factories are increasingly adopting automation and artificial intelligence to streamline operations and improve efficiency. Furthermore, with a growing emphasis on sustainability, there is a push toward the use of recycled materials in the production process.

Additionally, as urban areas continue to expand, the development of high-rise buildings requires more robust and innovative reinforcement solutions. This will likely drive research and development in creating advanced wire mesh products that can withstand greater stress.

Conclusion

Concrete wire mesh rolls are an indispensable aspect of modern construction. The factories that produce these vital materials contribute significantly to the quality and safety of infrastructures worldwide. As demands for stronger and more durable construction materials increase, the importance of efficient manufacturing processes and innovative solutions in the production of concrete wire mesh will only grow. It is essential for industry stakeholders to continue investing in technology and sustainable practices to meet these evolving challenges, ensuring that the foundations of our built environment remain solid for generations to come.

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025