-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Гру . 16, 2024 09:21 Back to list

High-Quality Custom Metal Wire Mesh Solutions for Industrial Applications

Custom Metal Wire Mesh Versatility and Applications

In today's fast-paced industrial landscape, the demand for specialized materials is growing rapidly. Custom metal wire mesh has emerged as a vital solution across various industries due to its versatility, durability, and aesthetic appeal. This article explores the significance of custom metal wire mesh, its manufacturing processes, and its wide-ranging applications.

Understanding Metal Wire Mesh

Metal wire mesh is composed of interwoven strands of metal wire, creating a grid-like pattern. It can be crafted from various materials, including stainless steel, aluminum, copper, and more. The size of the openings, the wire diameter, and the overall design can be tailored to meet specific requirements, making it an ideal choice for a multitude of projects.

Advantages of Customization

One of the significant advantages of custom metal wire mesh is the ability to tailor it to meet precise specifications. Customization involves defining the mesh's characteristics to optimize its performance for intended applications. Key factors that can be customized include

1. Material Type Different materials offer distinct properties. Stainless steel is known for its corrosion resistance, while aluminum is lightweight and easy to work with.

2. Wire Diameter The thickness of the individual wires can affect the mesh's strength, appearance, and function. Thicker wires provide increased strength, while thinner wires can offer finer filtration.

3. Opening Size The openings in the mesh can be designed to filter specific sizes of particles, making it suitable for applications ranging from filtration to security.

4. Weave Pattern The way the wires are woven together influences the mesh's flexibility and strength. Different weave patterns can enhance the aesthetic appeal and functional properties.

Manufacturing Process

The production of custom metal wire mesh typically involves several stages, including wire drawing, weaving, and finishing.

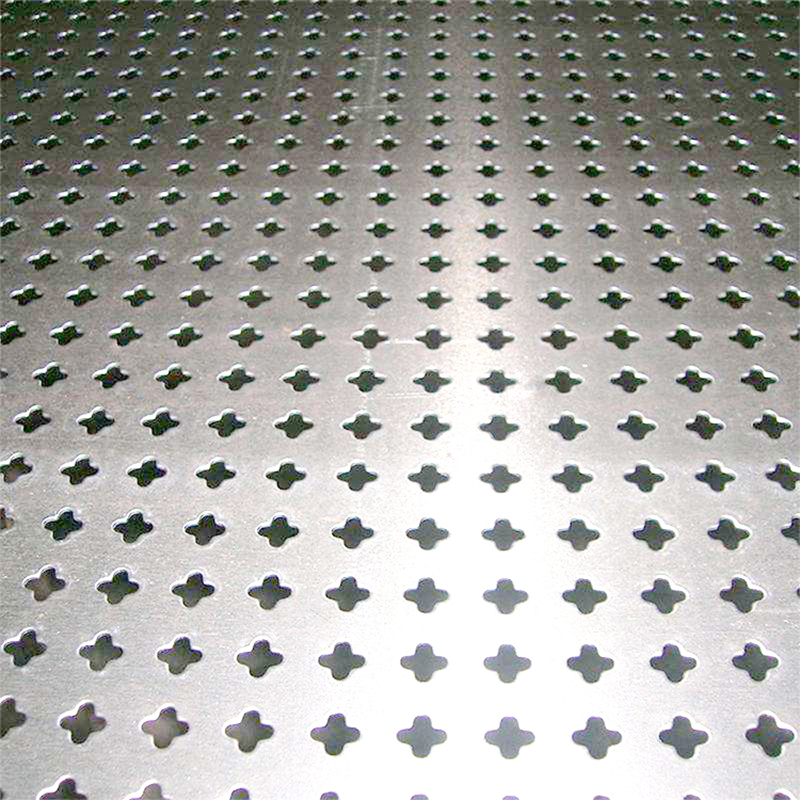

custom metal wire mesh

1. Wire Drawing High-quality metal rods are drawn into wire of specific diameters. This process ensures the wire possesses the necessary tensile strength and flexibility.

2. Weaving The drawn wire is woven together using automated machines or hand-crafted techniques, depending on the required design and specifications. Various weave patterns, such as plain weave, twill weave, and Dutch weave, can be implemented based on the application.

3. Finishing After weaving, the mesh can undergo various finishing processes, such as electroplating, powder coating, or galvanization. These processes enhance the wire mesh's durability and resistance to environmental factors.

Applications of Custom Metal Wire Mesh

The versatility of custom metal wire mesh allows it to serve multiple industries effectively

1. Construction Metal wire mesh is used in concrete reinforcement, fencing, and architectural applications. Its strength and adaptability make it ideal for structural supports and decorative elements.

2. Filtration In the chemical, pharmaceutical, and food industries, custom metal wire mesh provides an efficient means of filtration for liquids and gases, ensuring that contaminants are removed effectively.

3. Automotive In automotive manufacturing, wire mesh is often used in air filtration systems and protective grilles, serving both functional and aesthetic purposes.

4. Security Security applications benefit from wire mesh in the form of fencing, window guards, and barriers, providing safety without significant visibility obstruction.

5. Home Decor Custom metal wire mesh has recently been embraced in interior design, finding its way into light fixtures, room dividers, and artistic installations. Its modern look adds an industrial touch to any space.

Conclusion

Custom metal wire mesh offers an array of benefits that position it as a critical component across various industries. Its adaptability allows for tailored solutions that meet precise specifications, ensuring effectiveness in specialized applications. As industries continue to evolve, the role of custom metal wire mesh is likely to expand, paving the way for innovative designs and functionality that enhance both commercial and personal projects. Whether for industrial, aesthetic, or safety purposes, the value of custom metal wire mesh cannot be overstated—it is a testament to engineering ingenuity and versatility.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025