-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Лют . 13, 2025 16:35 Back to list

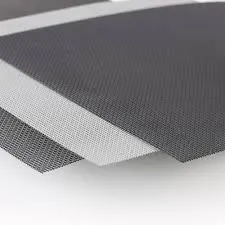

custom hexagonal wire mesh

Custom stainless wire mesh is swiftly becoming a go-to solution across various industries due to its unparalleled versatility and robustness. This meticulously engineered material exhibits an exceptional array of properties that cater to the specific needs of different sectors, from architecture to pharmaceuticals, and even to chemical processing. As a material specialist who has spent years delving into the complex world of wire mesh products, I have witnessed firsthand the transformative impact that custom stainless wire mesh brings.

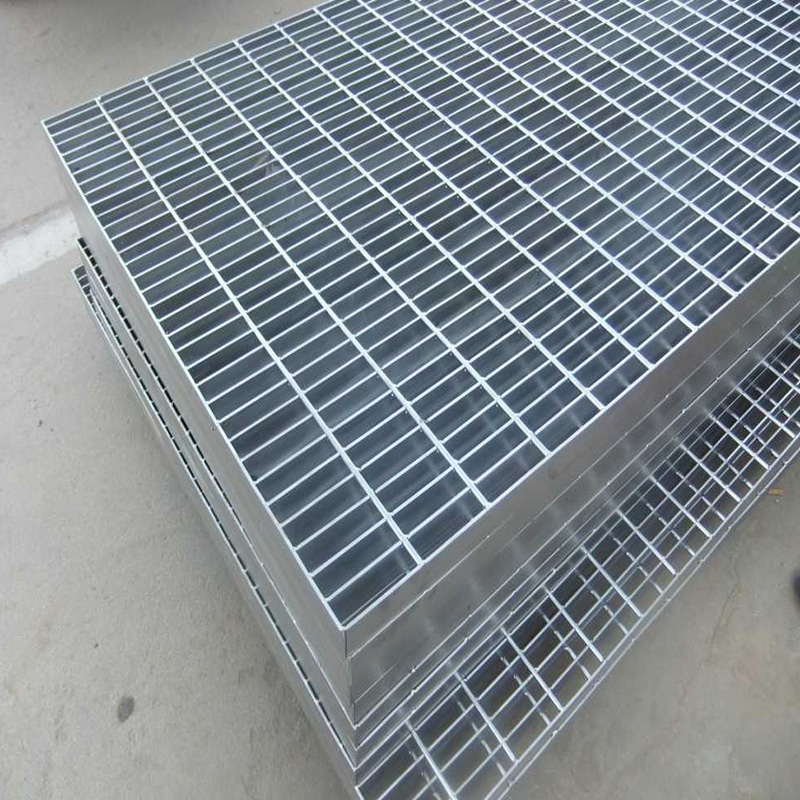

Beyond these professional applications, the authoritativeness of using stainless wire mesh comes through in its ability to contribute to ecological sustainability. Manufacturers can optimize mesh production to minimize wastage and enhance energy efficiency during the manufacturing process. Additionally, the long service life of stainless steel products promotes a shift towards more sustainable materials management, reducing the need for disposable alternatives and aligning with global environmental goals. Trustworthiness in custom stainless wire mesh is exemplified by its proven track record across various critical applications. This trust is rooted in the consistent performance and conformity to international quality standards, which manufacturers adhere to rigorously. By employing advanced technology and quality control measures, specialists deliver products that meet the precise requirements of each project, guaranteeing success and peace of mind for both designers and end-users. These characteristics underscore why custom stainless wire mesh is not merely a product but a strategic choice for industry leaders seeking reliability and innovation. Its ability to be tailored to specification, coupled with innate robustness and environmental benefits, position it as an essential material for today and the future. As industries continue to evolve, the demand for custom solutions that offer economic and performance advantages will only grow, reinforcing stainless wire mesh's status as a material of choice across the globe. In conclusion, leveraging custom stainless wire mesh across diverse industries is a testament to its perpetual relevance and adaptability. Through decades of development and application, this material continues to stand at the forefront of material technology, embodying the perfect balance of durability, flexibility, and environmental consciousness. As a well-regarded authority in the industry, I firmly advocate for the adoption of custom stainless wire mesh to enhance operational efficiency and design elegance — a true testament to modern engineering excellence.

Beyond these professional applications, the authoritativeness of using stainless wire mesh comes through in its ability to contribute to ecological sustainability. Manufacturers can optimize mesh production to minimize wastage and enhance energy efficiency during the manufacturing process. Additionally, the long service life of stainless steel products promotes a shift towards more sustainable materials management, reducing the need for disposable alternatives and aligning with global environmental goals. Trustworthiness in custom stainless wire mesh is exemplified by its proven track record across various critical applications. This trust is rooted in the consistent performance and conformity to international quality standards, which manufacturers adhere to rigorously. By employing advanced technology and quality control measures, specialists deliver products that meet the precise requirements of each project, guaranteeing success and peace of mind for both designers and end-users. These characteristics underscore why custom stainless wire mesh is not merely a product but a strategic choice for industry leaders seeking reliability and innovation. Its ability to be tailored to specification, coupled with innate robustness and environmental benefits, position it as an essential material for today and the future. As industries continue to evolve, the demand for custom solutions that offer economic and performance advantages will only grow, reinforcing stainless wire mesh's status as a material of choice across the globe. In conclusion, leveraging custom stainless wire mesh across diverse industries is a testament to its perpetual relevance and adaptability. Through decades of development and application, this material continues to stand at the forefront of material technology, embodying the perfect balance of durability, flexibility, and environmental consciousness. As a well-regarded authority in the industry, I firmly advocate for the adoption of custom stainless wire mesh to enhance operational efficiency and design elegance — a true testament to modern engineering excellence.

Next:

Latest news

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025