-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Гру . 11, 2024 22:01 Back to list

Custom Stainless Steel 316 and 304 Wire Mesh Solutions for Various Applications

Understanding Custom Wire Mesh The Benefits of SS 316 and SS 304

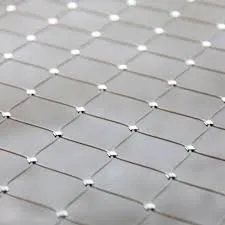

Wire mesh is a versatile material that has a wide array of applications across various industries, from agriculture to construction. When it comes to custom wire mesh, two stainless steel grades stand out for their durability and corrosion resistance SS 316 and SS 304. This article will delve into the characteristics of these materials, explore their differences, and highlight the advantages of utilizing custom wire mesh in various applications.

What is Wire Mesh?

Wire mesh, often referred to as wire cloth or wire screen, consists of intersecting wires that create a grid-like pattern. The wires can be woven together in various styles, producing different mesh sizes and openings. This allows for a broad range of specifications tailored to meet individual project requirements. Custom wire mesh can be produced to specific dimensions, aperture sizes, and wire diameters, making it a favored choice in numerous sectors.

Stainless Steel Grades SS 316 vs

. SS 304Stainless steel is an alloy that includes iron, carbon, and a minimum of 10.5% chromium, providing excellent resistance to corrosion. Among the various grades of stainless steel available, SS 316 and SS 304 are the most commonly used in wire mesh applications.

1. SS 304 Known as the most versatile stainless steel alloy, SS 304 is often used for its resistance to oxidation and corrosion in a variety of environments. It contains a lower nickel content compared to SS 316 and is less resistant to chlorides. Therefore, while it performs well in many settings, it is not as ideal for applications that involve exposure to harsh chemicals or saltwater.

2. SS 316 This grade contains molybdenum, which enhances its resistance to pitting and crevice corrosion, making it particularly suitable for marine environments or applications involving acidic and chloride-rich substances. SS 316 is often the preferred choice in chemical processing, food production, and medical applications due to its superior durability.

Benefits of Custom Wire Mesh

custom wire mesh ss 316 304

1. Tailored Solutions One of the primary advantages of custom wire mesh is the ability to create specific solutions for unique applications. Businesses can specify the dimensions, mesh size, wire gauge, and material grade, ensuring that they receive a product that meets their exact needs.

2. Enhanced Durability Using high-quality materials like SS 316 and SS 304 ensures that the wire mesh is capable of withstanding harsh conditions. This durability translates to longer service life and reduced need for replacement, lowering overall operational costs.

3. Corrosion Resistance Both SS 316 and SS 304 offer excellent corrosion resistance; however, SS 316 offers superior protection in extremely challenging environments. This is especially crucial for industries such as pharmaceuticals and marine applications, where exposure to corrosive substances is common.

4. Versatility Custom wire mesh can be designed for a multitude of purposes, including filtration, fencing, and reinforcement. Its adaptability makes it suitable for applications in agriculture, construction, architecture, and manufacturing, among others.

5. Cost-Effectiveness Investing in custom wire mesh may have a higher upfront cost than standard products, but its durability and tailored design often lead to savings in the long run. Fewer replacements and repairs mean lower costs associated with maintenance and material procurement.

Applications of Custom Wire Mesh

The applications of custom wire mesh are vast. In the construction sector, it is used for concrete reinforcement, whereas in agriculture, it serves as fencing and animal enclosures. In the food and beverage industry, SS 316 wire mesh is utilized for screens and filters due to its hygienic properties. Similarly, it finds applications in water treatment facilities, mining, and even decorative elements in architecture.

Conclusion

Custom wire mesh made from SS 316 and SS 304 offers businesses a range of benefits, including tailored design, enhanced durability, and superior corrosion resistance. As industries continue to evolve, the demand for specialized materials like custom wire mesh will only grow, making it an essential component in ensuring the efficiency and longevity of various operations. Understanding the properties and applications of these materials allows businesses to make informed decisions, thereby optimizing their processes and achieving greater success. Whether for industrial use or specialized applications, investing in high-quality custom wire mesh is a decision that promises reliability and performance.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025