-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Лют . 08, 2025 05:14 Back to list

custom hexagonal wire mesh

Custom wire mesh products made from SS 316 and SS 304 have become a cornerstone in various industrial applications due to their unparalleled qualities. Whether you're in construction, manufacturing, or design, understanding the distinct characteristics and benefits of these materials can yield optimal results in your projects.

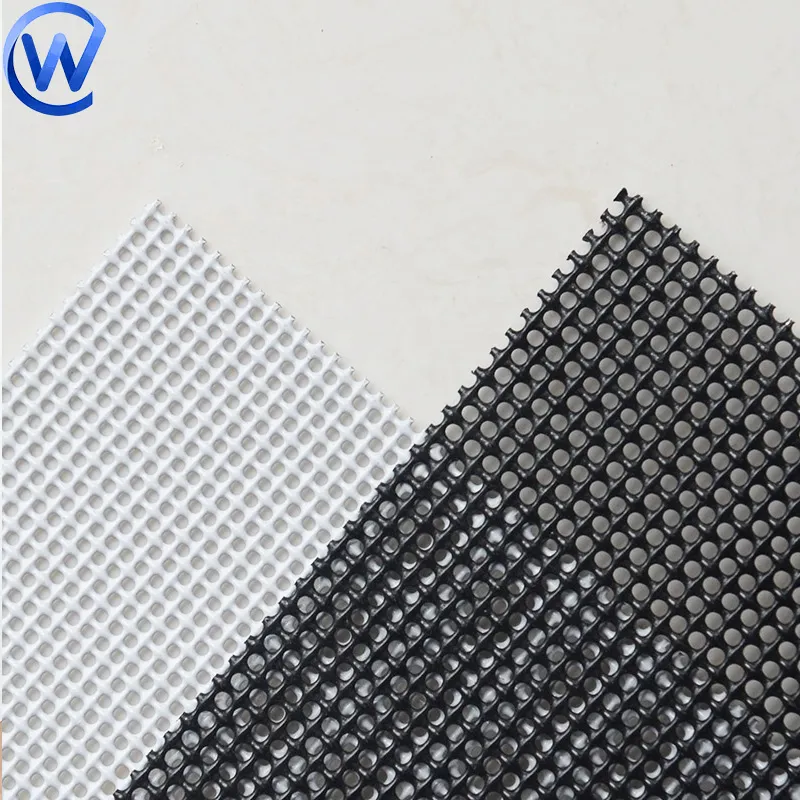

From a product expertise perspective, customization allows clients to select optimal wire diameters, weave patterns, and mesh openings, each parameter contributing to the final product's performance in its intended application. Openings can be adjusted to balance between airflow and security, and weave styles can vary from plain to twill, influencing not only strength but also visual appeal. Such flexibility ensures that each application receives a product that not only meets but exceeds expectations. Furthermore, the production of these custom wire meshes underscores reliability and trustworthiness. Reputable manufacturers adhere to stringent quality control processes, ensuring that each mesh meets specific industry standards and client specifications. This commitment to quality not only guarantees performance but also inspires confidence in end-users who depend on these products to maintain critical operations. Incorporating custom wire mesh ss 316 and 304 into your projects benefits from a profound understanding of their properties and applications. Engaging with seasoned professionals who specialize in these materials can lead to more innovative solutions, enhancing overall productivity and effectiveness. Investing in high-quality stainless steel wire mesh equates to enhanced durability, reduced maintenance, and a lasting impression—factors crucial for any successful project. Consider harnessing the power of custom wire mesh products to bring your project visions to life. Trust in the resilience, adaptability, and professionalism that these materials bring, ensuring that your endeavors are supported by industry-leading solutions designed to withstand the test of time and environment.

From a product expertise perspective, customization allows clients to select optimal wire diameters, weave patterns, and mesh openings, each parameter contributing to the final product's performance in its intended application. Openings can be adjusted to balance between airflow and security, and weave styles can vary from plain to twill, influencing not only strength but also visual appeal. Such flexibility ensures that each application receives a product that not only meets but exceeds expectations. Furthermore, the production of these custom wire meshes underscores reliability and trustworthiness. Reputable manufacturers adhere to stringent quality control processes, ensuring that each mesh meets specific industry standards and client specifications. This commitment to quality not only guarantees performance but also inspires confidence in end-users who depend on these products to maintain critical operations. Incorporating custom wire mesh ss 316 and 304 into your projects benefits from a profound understanding of their properties and applications. Engaging with seasoned professionals who specialize in these materials can lead to more innovative solutions, enhancing overall productivity and effectiveness. Investing in high-quality stainless steel wire mesh equates to enhanced durability, reduced maintenance, and a lasting impression—factors crucial for any successful project. Consider harnessing the power of custom wire mesh products to bring your project visions to life. Trust in the resilience, adaptability, and professionalism that these materials bring, ensuring that your endeavors are supported by industry-leading solutions designed to withstand the test of time and environment.

Next:

Latest news

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025