-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Гру . 23, 2024 12:10 Back to list

flat expanded metal mesh factories

Exploring Flat Expanded Metal Mesh Factories Innovations and Applications

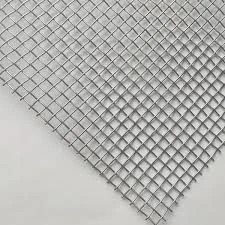

Flat expanded metal mesh is a versatile material widely used across various industries due to its strength, durability, and aesthetic appeal. Manufactured through a specialized process of slitting and stretching metal sheets, this mesh comes in a range of sizes and patterns tailored to specific needs. As the demand for this product grows, several factories worldwide have emerged, each specializing in the production of high-quality flat expanded metal mesh.

The Manufacturing Process

The creation of flat expanded metal mesh begins with selecting the appropriate metal, typically aluminum, steel, or stainless steel, depending on the intended application. The metal sheet is then subjected to a series of slits before being expanded. During the expansion process, the metal is stretched, creating a network of diamond-shaped holes. This unique structure not only enhances the mesh's strength-to-weight ratio but also provides an attractive visual appearance, making it suitable for architectural applications alongside industrial uses.

Factories that focus on flat expanded metal mesh are equipped with advanced machinery capable of handling large volumes of material while ensuring precision in every cut and expansion. Automation plays a significant role in modern manufacturing, with computerized systems that optimize production efficiency and reduce waste. Quality control is paramount, with rigorous testing of final products to ensure they meet industry standards for durability and performance.

Applications Across Industries

Flat expanded metal mesh finds applications in numerous sectors, including construction, automotive, aerospace, and fashion.

1. Construction and Architecture In the construction industry, flat expanded metal mesh is utilized for facades, security screens, and railings. Its lightweight yet sturdy nature allows for innovative architectural designs while ensuring structural integrity. The mesh can be coated or painted to complement building aesthetics, making it a favored choice among architects.

2. Automotive Industry In automotive manufacturing, expanded metal mesh serves as a protective component, often used in grilles, underbody shields, and as reinforcement in various panels. Its ability to withstand impact while providing airflow makes it ideal for vehicle applications.

flat expanded metal mesh factories

3. Aerospace Sector The aerospace industry benefits from flat expanded metal mesh due to its combination of lightness and strength. It is often utilized in aircraft interiors, where weight reduction is critical. Furthermore, expanded metal can be used in structural applications, contributing to aircraft safety.

4. Fashion and Art Beyond industrial applications, flat expanded metal mesh has found its way into the world of fashion and art. Designers have begun to integrate this material into clothing, accessories, and installations, appreciating its unique texture and the interesting interplay of light and shadow it creates.

Sustainability Considerations

As global awareness regarding sustainability increases, many expanded metal mesh factories are adopting eco-friendly practices. The recycling of scrap metal and the use of sustainable materials are becoming standard in manufacturing processes. Factories are also exploring green energy sources to power their operations, further minimizing their environmental footprint.

Moreover, the long lifespan and durability of flat expanded metal mesh contribute to sustainable construction practices, as it reduces the need for frequent replacements. This aligns with contemporary trends towards sustainability in design and construction, appealing to environmentally conscious consumers and businesses alike.

Future Trends

Looking towards the future, the flat expanded metal mesh industry is poised for growth, driven by technological advancements and innovative applications. The integration of smart technologies, such as sensors embedded within the mesh for safety monitoring, is on the horizon. Additionally, customization options are expanding, allowing factories to respond more effectively to specific client needs.

In conclusion, flat expanded metal mesh factories play a crucial role in providing a material that is not only functional but also aesthetically pleasing. The versatility of this product, combined with modern manufacturing techniques and sustainable initiatives, ensures that it will continue to be a vital component in many industries. As demand grows and innovation persists, flat expanded metal mesh will undoubtedly evolve, furthering its applications in manufacturing, construction, design, and beyond.

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

AI SEO Optimizer

NewsJul.20,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025