-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Жов . 16, 2024 14:39 Back to list

galvanized wire mesh fence factories

Understanding Galvanized Wire Mesh Fence Factories

Galvanized wire mesh fences have become increasingly popular in various sectors, including agricultural, industrial, and residential applications. This popularity can be attributed to their durability, corrosion resistance, and versatility. The production of these fences typically takes place in specialized factories that employ sophisticated manufacturing processes. In this article, we will delve into the operations of galvanized wire mesh fence factories, highlighting their significance, manufacturing techniques, and the benefits they offer.

One of the main functions of galvanized wire mesh fences is to provide security and protection. These fences are commonly used to enclose properties, contain livestock, and secure construction sites. Due to their robust nature, they can withstand harsh environmental conditions, including heavy rain, wind, and exposure to chemicals. The galvanization process, which involves coating the wire in zinc, significantly enhances the wire’s resistance to rust and deterioration, ensuring a long lifespan.

In galvanized wire mesh fence factories, the manufacturing process begins with the procurement of high-quality steel wire. The wire is then processed through several stages, including drawing, which reduces the diameter of the wire to the desired size. Once the wire has attained the right thickness, it undergoes galvanization. This is typically achieved using either hot-dip galvanization, where the wire is submerged in molten zinc, or electro-galvanization, which involves applying a zinc coating through an electrochemical process. Both methods provide effective protection against corrosion, but hot-dip galvanization is often favored for its superior durability.

galvanized wire mesh fence factories

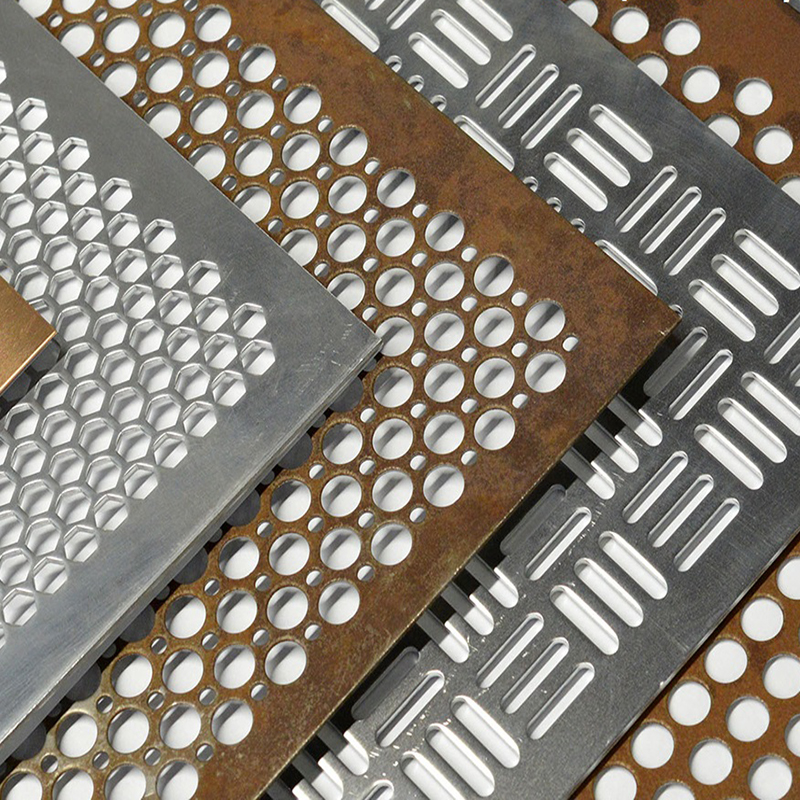

After galvanization, the wire is woven or welded into mesh panels. Welding machines are used to create a sturdy and stable mesh structure, while weaving offers flexibility in design and application. Factories may produce different mesh sizes and patterns, catering to various customer needs. Once the fencing panels are formed, they undergo quality control checks to ensure compliance with industry standards. This quality assurance is critical, as it guarantees that the final product will meet the expected durability and performance criteria.

Additionally, many galvanized wire mesh fence factories focus on sustainable manufacturing practices. This includes recycling excess materials, reducing waste, and minimizing water and energy consumption during production. Some factories are also adopting innovative technologies, such as automated machinery and advanced quality control systems, to enhance efficiency and reduce production costs.

The market for galvanized wire mesh fences is expanding, driven by an increasing demand for quality security solutions across different sectors. As urbanization and industrialization continue to rise, the need for effective fencing solutions remains paramount. This presents a lucrative opportunity for galvanized wire mesh fence factories to grow and innovate.

In conclusion, galvanized wire mesh fence factories play a pivotal role in producing reliable and long-lasting fencing solutions. Through advanced manufacturing processes and stringent quality control measures, these factories ensure that their products not only meet but exceed customer expectations. As the demand for such fences continues to grow, these factories will remain essential to the security and infrastructure of modern society. Their commitment to quality, sustainability, and innovation will shape the future of fencing solutions worldwide.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025