-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Лис . 22, 2024 08:22 Back to list

heavy duty wire mesh screens factory

Heavy Duty Wire Mesh Screens A Comprehensive Overview of Their Manufacturing and Applications

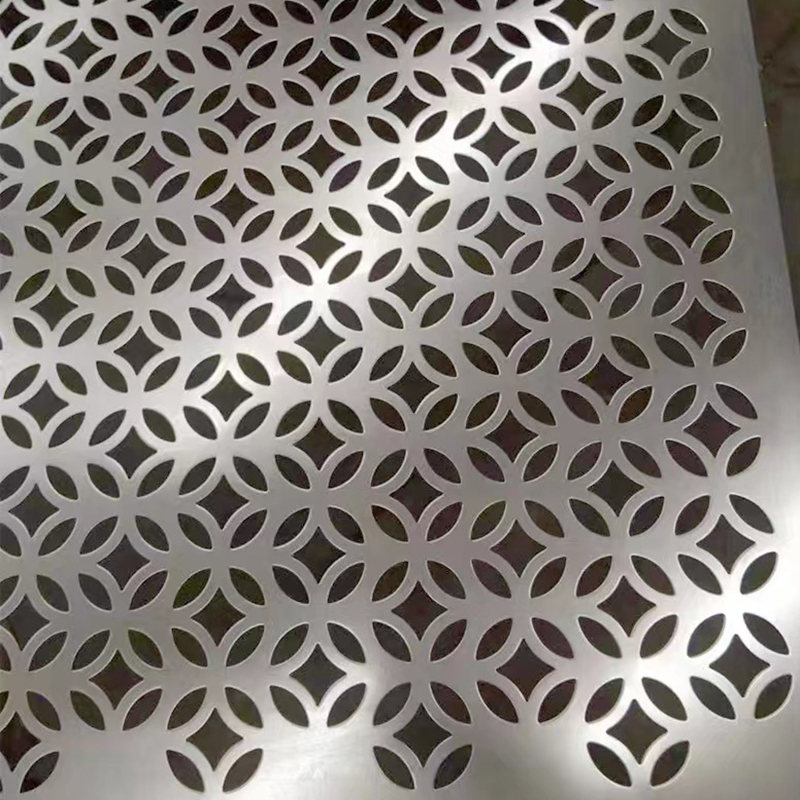

Heavy duty wire mesh screens are essential components in numerous industrial applications, characterized by their durability, versatility, and strength. These screens are constructed using robust wire materials that withstand significant stress, making them ideal for use in environments where conventional materials would fail. This article explores the manufacturing processes, key features, and diverse applications of heavy duty wire mesh screens, providing a thorough understanding of their importance in various industries.

Manufacturing Process

The manufacturing of heavy duty wire mesh screens involves several critical steps aimed at ensuring the final product meets rigorous standards of quality and performance. The process typically begins with selecting the right materials. High-quality stainless steel, carbon steel, or other alloys are commonly used due to their resistance to corrosion and excellent tensile strength.

The chosen wire is then precision-woven into various mesh patterns, with the weave type being specifically designed to meet the needs of the intended application. Common weave types include plain weave, twill weave, and reinforced weave, each offering distinct advantages in terms of filtration efficiency and mechanical strength.

After weaving, the screens undergo a series of finishing processes, which may include cutting, welding, and coating. Cutting ensures that the screens are fabricated to the required sizes, while welding may be used to add structural integrity, especially for larger or more complex designs. Surface coatings, such as galvanization or powder coating, provide additional protection against environmental factors, enhancing the longevity of the screens.

Key Features

One of the standout features of heavy duty wire mesh screens is their excellent load-bearing capacity. These screens are engineered to handle a range of weights and pressures, making them suitable for demanding applications. Furthermore, their resistance to wear and tear makes them ideal for use in harsh conditions, such as those found in mining, construction, and agriculture.

Another significant characteristic is their versatility. Heavy duty wire mesh screens can be manufactured in various mesh sizes, opening dimensions, and wire thicknesses to cater to specific requirements. This adaptability allows them to effectively filter particles of different sizes, ensuring optimal performance in various filtration and separation applications.

heavy duty wire mesh screens factory

Moreover, heavy duty wire mesh screens are relatively low maintenance. Their durable nature means that they do not require frequent replacements, and when maintained properly, they can perform effectively for years. This cost-effectiveness, combined with their strength, makes them a preferred choice in many industrial settings.

Applications

Heavy duty wire mesh screens find applications across a wide range of industries. In the mining and quarrying sector, they are used for screening and classification of rocks, ores, and minerals. Their ability to separate materials based on size helps in efficient processing and recovery.

In the construction industry, such screens are utilized for scaffolding, safety barriers, and as protective fencing. Their sturdiness ensures that they can withstand the rigors of construction work while providing necessary safety features.

The agriculture industry also benefits from heavy duty wire mesh screens, which are used for sorting grains, filtering water, and even in livestock enclosures. Their durability in outdoor environments makes them a reliable choice for farmers and agricultural businesses.

Waste management and recycling industries make extensive use of these screens for sorting and separating materials. By effectively filtering debris and recyclables, heavy duty wire mesh screens contribute to more efficient recycling processes and waste management systems.

Conclusion

Heavy duty wire mesh screens are crucial in various industrial sectors, offering remarkable strength, durability, and versatility. Their manufacturing process ensures high-quality products that can withstand tough conditions, making them an integral part of many applications ranging from mining and construction to agriculture and waste management. As industries continue to evolve and place greater demands on materials, the importance of heavy duty wire mesh screens will undoubtedly continue to grow, affirming their role in modern industrial practices.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025