-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Лют . 16, 2025 10:36 Back to list

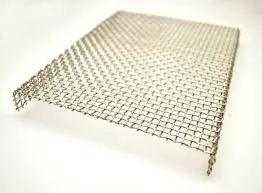

Perforated Metal Mesh

Perforated metal sheets stand out as a versatile material in various industries, from construction to design, owing to their functionality and aesthetic appeal. Understanding the factors influencing the price of high-quality perforated metal sheets can offer buyers substantial expertise when making purchasing decisions. This guide delves into the key considerations and industry insights crucial for evaluating the cost and justifying investment in these materials, intertwining real-world experiences and authoritative knowledge.

Real-world experience emphasizes the importance of sourcing materials from reputable manufacturers who adhere to rigorous quality standards. High-quality perforated sheets should meet industry standards such as ASTM or ISO, ensuring reliability and performance. Partnering with established suppliers builds trust and guarantees access to expert guidance, potentially preventing costly mishaps down the line. Investing in perforated metal sheets is not merely a monetary transaction but a strategic decision that requires careful consideration of intended use and environmental factors. Understanding specific project requirements—like load capacity, exposure to elements, and aesthetic appeal—aligns product choice with practical needs, optimizing cost-efficiency and functional benefits. In industries where acoustic performance is crucial, selecting perforated sheets with appropriate hole size and pattern can dramatically enhance sound absorption. This proves instrumental in architectural design and construction, where noise reduction significantly impacts human experience and comfort. Sustainability has emerged as a crucial consideration in material selection. Eco-conscious buyers might prioritize manufacturers who implement sustainable practices, such as recycling and reducing production waste. Certain materials, like aluminum, are inherently sustainable due to their recyclability, potentially influencing price dynamics as industries pivot towards greener practices. Navigating the price landscape of perforated metal sheets demands an astute understanding of quality indicators and their alignment with project needs. An investment in high-quality perforated sheets offers dividends not just in durability and performance but in the architectural flexibility to innovate and realize futuristic designs. As the market evolves, staying informed of technological advancements and supplier reputations ensures wise investment. In conclusion, the perceived cost of high-quality perforated metal sheets reflects more than immediate material value. It embodies long-term utility, aesthetic potential, and adherence to environmental considerations, all of which transform expenditure into a strategic asset. Meticulous research and selection based on comprehensive expertise secure functional, economic, and environmental benefits critical to contemporary applications.

Real-world experience emphasizes the importance of sourcing materials from reputable manufacturers who adhere to rigorous quality standards. High-quality perforated sheets should meet industry standards such as ASTM or ISO, ensuring reliability and performance. Partnering with established suppliers builds trust and guarantees access to expert guidance, potentially preventing costly mishaps down the line. Investing in perforated metal sheets is not merely a monetary transaction but a strategic decision that requires careful consideration of intended use and environmental factors. Understanding specific project requirements—like load capacity, exposure to elements, and aesthetic appeal—aligns product choice with practical needs, optimizing cost-efficiency and functional benefits. In industries where acoustic performance is crucial, selecting perforated sheets with appropriate hole size and pattern can dramatically enhance sound absorption. This proves instrumental in architectural design and construction, where noise reduction significantly impacts human experience and comfort. Sustainability has emerged as a crucial consideration in material selection. Eco-conscious buyers might prioritize manufacturers who implement sustainable practices, such as recycling and reducing production waste. Certain materials, like aluminum, are inherently sustainable due to their recyclability, potentially influencing price dynamics as industries pivot towards greener practices. Navigating the price landscape of perforated metal sheets demands an astute understanding of quality indicators and their alignment with project needs. An investment in high-quality perforated sheets offers dividends not just in durability and performance but in the architectural flexibility to innovate and realize futuristic designs. As the market evolves, staying informed of technological advancements and supplier reputations ensures wise investment. In conclusion, the perceived cost of high-quality perforated metal sheets reflects more than immediate material value. It embodies long-term utility, aesthetic potential, and adherence to environmental considerations, all of which transform expenditure into a strategic asset. Meticulous research and selection based on comprehensive expertise secure functional, economic, and environmental benefits critical to contemporary applications.

Next:

Latest news

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025