-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Сер . 01, 2024 04:21 Back to list

Optimizing Production Techniques for High-Quality Perforated Panel Manufacturing in Modern Factories

The Importance of Perforated Panel Factories in Modern Construction

In recent years, the architectural and construction industries have seen significant innovations that integrate functionality, aesthetics, and sustainability. One such innovation is the use of perforated panels, which are increasingly becoming a staple in building design and construction. Perforated panel factories play a crucial role in the manufacturing of these versatile materials, contributing to diverse applications across various sectors.

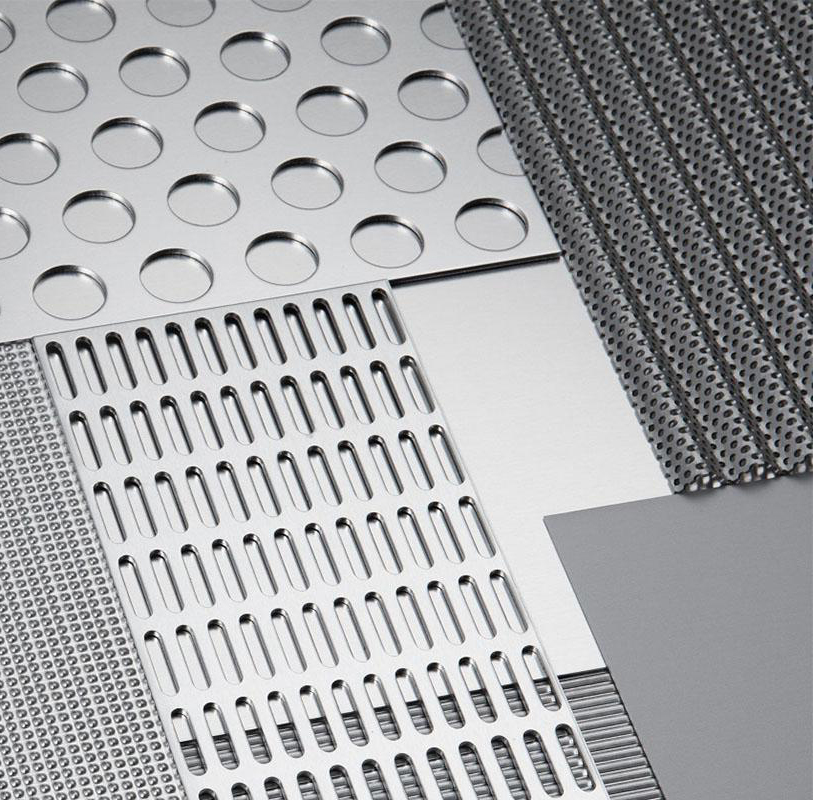

Perforated panels are intricately designed sheets of metal, plastic, or other materials with a series of holes punched through them. The configurations of these holes vary widely, allowing for creative designs that serve multiple purposes. The most common applications include architectural facades, interior wall coverings, ceiling tiles, and even acoustic treatments. The perforations not only provide aesthetic appeal but also enhance functionality, offering benefits such as light filtration, ventilation, and sound absorption.

The Importance of Perforated Panel Factories in Modern Construction

Quality perforated panel factories are equipped with advanced machinery and technology that allow for precise perforation patterns and high-quality finishes. This precision is vital, as the spacing and size of the holes can dramatically affect both the aesthetic and functional properties of the panel. Factories often offer customization options, enabling architects and designers to specify their requirements and create unique solutions tailored to their projects. This adaptability fosters collaboration between manufacturers and designers, leading to innovative products that push the boundaries of architectural design.

perforated panel factory

Additionally, perforated panels are known for their durability and low maintenance. Materials like aluminum, steel, and certain plastics are commonly used due to their resistance to weather elements and corrosion. This makes them an ideal choice for outdoor applications, such as cladding for commercial buildings, where longevity and performance are crucial. Manufacturers are increasingly focusing on using coatings and treatments that extend the lifespan of these panels, making them even more appealing to clients.

Furthermore, the aesthetic versatility of perforated panels cannot be overstated. They can be used to create striking visual effects, enhancing both the interior and exterior of buildings. From modern to traditional designs, perforated panels can be integrated seamlessly into various architectural styles. Many factories now offer a range of finishes and colors, allowing clients to choose options that align with their design vision.

As urbanization continues to grow and the demand for innovative building solutions increases, the role of perforated panel factories becomes ever more critical. These manufacturers not only provide essential materials but also contribute to the overall advancement of construction practices. By embracing new technologies and sustainable practices, perforated panel factories are paving the way for a more efficient and aesthetically pleasing built environment.

In conclusion, perforated panel factories are at the forefront of a significant trend in modern construction. Their ability to combine aesthetics with functionality while promoting sustainability and energy efficiency makes them indispensable in today’s architectural landscape. As demand grows for customizable and innovative building materials, these factories will continue to play a vital role in shaping the future of construction.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025