-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Жов . 04, 2024 22:35 Back to list

Perforated Metal Sheet Manufacturing and Supply Solutions for Various Industries

The Role of Perforated Sheet Metal Factories in Modern Manufacturing

In the contemporary manufacturing landscape, perforated sheet metal has emerged as a key material, widely utilized across various industries, including construction, automotive, aerospace, and more. The factories dedicated to producing perforated sheet metal play a vital role in meeting the growing demand for this versatile product.

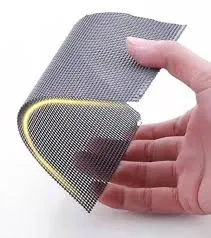

Perforated sheet metal is characterized by its array of holes or openings that can vary in size, shape, and pattern. These perforations serve multiple functions, such as allowing air, light, and sound to pass through while maintaining structural integrity. The production process involves taking flat sheets of metal—commonly steel, aluminum, or stainless steel—and using advanced machinery to create precise holes. This process can adapt to a diverse range of specifications, providing manufacturers with flexibility and custom solutions.

The Role of Perforated Sheet Metal Factories in Modern Manufacturing

Moreover, the aesthetics of perforated sheet metal cannot be overlooked. Many architectural designs incorporate this material for its visual appeal as well as its functional characteristics. Buildings can achieve a unique look while promoting airflow and light penetration, enhancing the overall design while being practical. Factories producing decorative perforated sheet metal offer a range of patterns that cater to the creative needs of designers, architects, and engineers.

perforated sheet metal factory

The versatility of perforated sheet metal also extends to its applications in various industries. In the construction sector, it is often used for facades, sunshades, and balustrades, providing both safety and style. In the automotive industry, manufacturers utilize perforated metals in various components, including grills and exhaust systems, where sound and heat dissipation are critical. Additionally, in the electronics field, perforated sheets are used in cabinetry and device housing to keep equipment cool while allowing sound to escape.

Sustainability is another crucial factor driving the growth of perforated sheet metal factories. Many manufacturers are now focusing on producing eco-friendly products by utilizing recycled materials and implementing energy-efficient processes. This commitment to sustainability not only helps reduce waste but also appeals to environmentally conscious consumers and businesses seeking to minimize their ecological footprint.

To ensure high-quality production, perforated sheet metal factories invest in state-of-the-art machinery and skilled workforce. Computer numerical control (CNC) technology enables precise hole placement, and automated systems enhance production efficiency and consistency. Continuous training for workers is essential to keep pace with new technologies and processes, ensuring that the factory can meet diverse customer needs while adhering to stringent quality standards.

In conclusion, perforated sheet metal factories are essential players in the manufacturing industry, providing a critical material that blends function with innovation. As technology continues to advance and the demand for sustainable practices grows, these factories will remain at the forefront of the market, shaping the future of design and industry applications while contributing to environmental stewardship. In a world where efficiency, aesthetics, and sustainability are increasingly important, the significance of perforated sheet metal cannot be overstated.

-

Premium Concertina Wire Manufacturer Global Exporters & Suppliers

NewsApr.29,2025

-

Galvanized Farm Fencing Wire Supplier Durable & Rust-Resistant

NewsApr.29,2025

-

Industrial Fence Manufacturer Durable & Custom Solutions for Export

NewsApr.29,2025

-

Stainless Steel Bird Spikes Durable & Effective Bird Deterrent

NewsApr.28,2025

-

Premium Stainless Steel Drain Grates Exporter & Manufacturer

NewsApr.28,2025

-

Durable Galvanized Razor Wire Manufacturer & Exporter High Security

NewsApr.28,2025