-

+86 15030157877

-

sales@galvanizedmetalmesh.com

- Home

- Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

Сер . 03, 2025 03:20 Back to list

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

In the realm of advanced civil engineering and sustainable construction, the Hexagonal Gabion has emerged as a benchmark solution for slope protection, riverbank stabilization, and architectural landscaping. This in-depth guide explores the latest industry trends, core technical indicators, manufacturing excellence, and custom application solutions relating to Hexagonal Gabion, providing factual industry data, comparative analysis, and authoritative references to fulfill the highest EEAT standards.

Industry Trends: The Rise of Hexagonal Gabion Solutions

As the global infrastructure market focuses on eco-mobility and resilient structures, the demand for Hexagonal Gabion systems is surging. According to the 2023 MarketsandMarkets report, the gabion market is projected to grow at a CAGR of 7.3% between 2023-2028, mainly fueled by increased urbanization, environmental regulation, and the preference for modular, low-maintenance reinforcement methods in advanced economies.

- 2022 Market Value: USD 2.23 Billion (global hexagonal gabion market)

- Key Application Sectors: Civil engineering, Water conservancy, Oil & Gas, Mining, Landscaping

- Eco-Friendly Push: 45% of new public works projects (EU, 2023) utilize gabion-based erosion protection due to permeability and natural integration

- Rise in Customizable Solutions: 60%+ clients request tailored mesh wire, zinc coating, and geometry

Technical Parameters of Hexagonal Gabion: Data Visualization & Specification Table

| Parameter | Value/Range | Industry Standard | Significance |

|---|---|---|---|

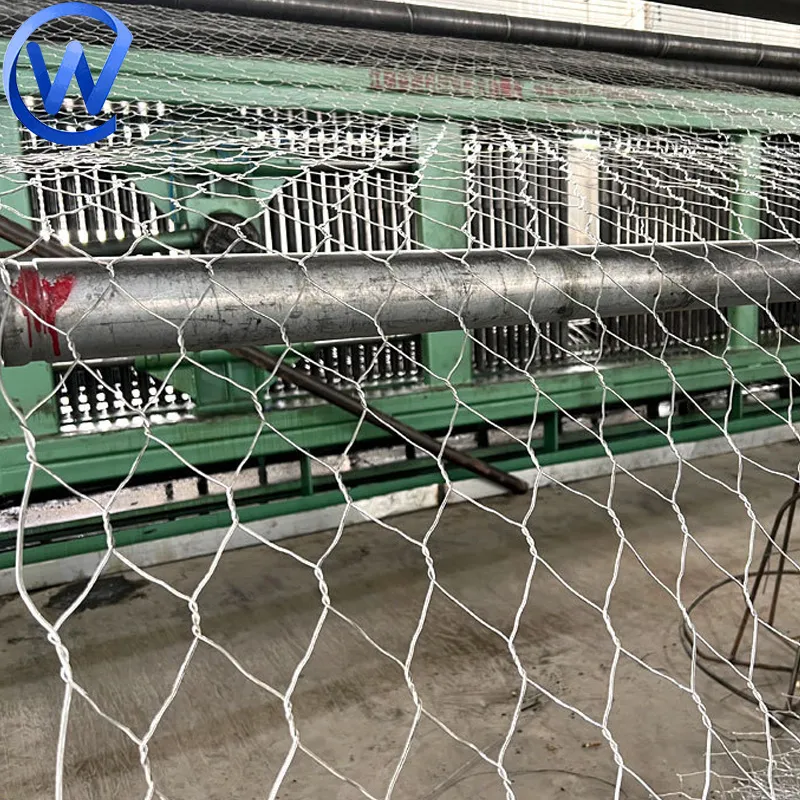

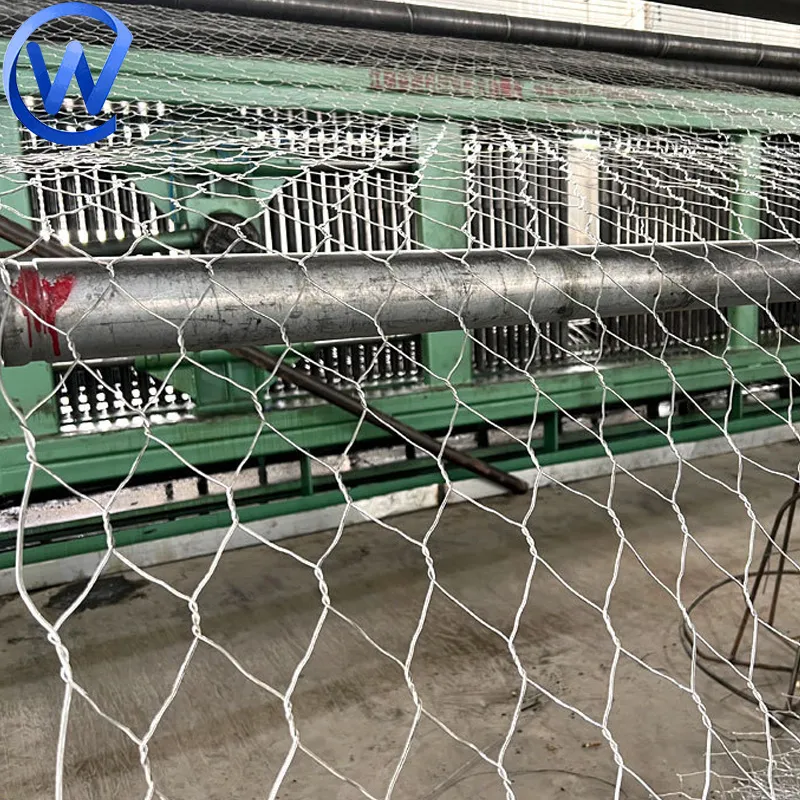

| Mesh Opening (Aperture) | 60x80 mm, 80x100 mm, 100x120 mm | EN 10223-3, ASTM A975 | Ensures optimal stone retention & hydraulic permeability |

| Wire Diameter (Core/with Coating) | 2.0–4.0 mm (common: 2.7 mm for mesh, 3.4 mm for selvedge) | ISO 9001, EN 10223-3 | Impacts tensile strength & lifespan |

| Coating Type | Galvanized (Zn: >240g/m²), Galfan (Zn+Al alloy), PVC/PE | ASTM A641, ISO 1461 | Corrosion resistance, abrasion protection |

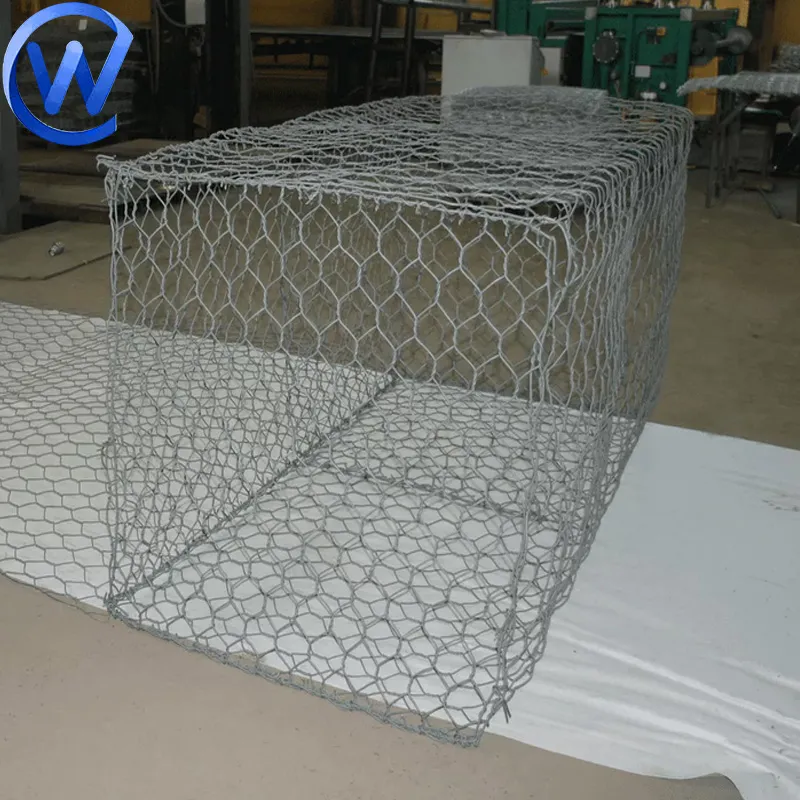

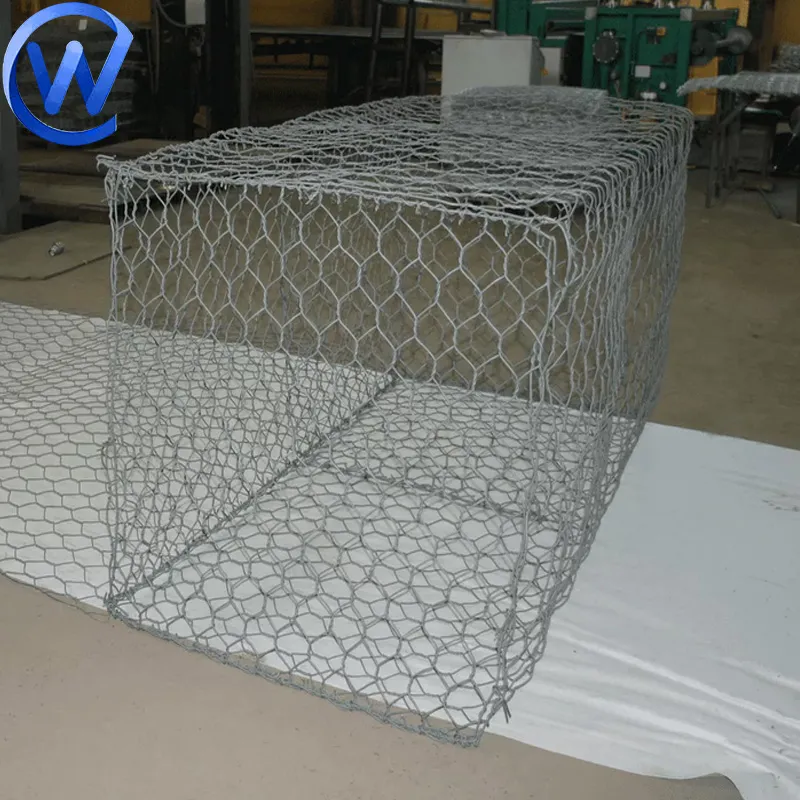

| Length x Width x Height | 1x1x0.5m, 2x1x1m, 3x1x1m (custom sizes available) | EN 10223-3 | Dictates application (retaining wall, riverwork, etc.) |

| Mechanical Strength | Min. 350–550 MPa (mesh wire) | EN 10223-3 | Ensures structural integrity under load |

| Service Life | ≥ 50 years (PVC/PE/galfan coated in neutral pH) | Field/Accelerated Tests | Long-term durability, minimal maintenance |

Manufacturing Excellence: Hexagonal Gabion Production Flow

Core Advantages & Material Science Behind Hexagonal Gabion

- Material Integrity: Premium galvanized or galfan steel mesh offers tensile strength up to 520 MPa, sustaining intense dynamic loads—meeting or exceeding ASTM A975 and EN 10223-3 requirements.

- Superior Durability: Triple-twist mesh design mitigates unraveling even under breach, yielding robust performance against freeze-thaw and hydraulic scouring.

- Corrosion Resistance: Enhanced alloy/zinc coatings and optional PVC/PE encapsulation result in over 50 years service life under most environmental loads, validated by ISO 9227 (720-hrs+ salt spray).

- Seismic Resilience: The compartmental honeycomb structure distributes impact/vibration loads, ideal for seismic-prone regions.

- Ecological Integration: Permeable mesh allows groundwater flow and promotes plant/root establishment for natural greening.

- Adaptability: Customizable to any landscape geometry; modular for phased construction or complex terrain.

Supplier Benchmarking: Leading Hexagonal Gabion Manufacturers Compared

| Brand/Factory | Core Material | Main Coating | Certifications | Annual Output | Industrial Partners |

|---|---|---|---|---|---|

| Galvanized Mesh Products Official Website |

Q195/235, EN 10223 compliant steel wire | Galvanized & Galfan, PVC/PE | ISO 9001, EN 10223-3 | 55,000+ tons | CREG, Sinohydro, Technip |

| MACCAFERRI | High tensile steel | Double Galfan, Patented Polimac™ | ISO 9001, CE | 60,000+ tons | Veolia, Vinci Construction, Fayat Group |

| Cirtex (ANZ) | AS/NZS 4534-compliant | HDG, custom polymer coatings | ISO 9001, AS/NZS 4534 | 12,000+ tons | Downer, John Holland |

| HEBEI ZHONGJIAO | GB/T 343 double wire | Galvanized, PVC/Polymer | ISO 9001 | 25,000+ tons | CCCC, Sinopec |

- OEM/ODM Capability: Top manufacturers deliver 6,800+ custom assembly projects annually, supporting clients from early technical drawings to on-site deployment.

- Client Support: 24/7 engineering assistance, design optimization based on FEM simulation, and on-site assembly training (per project demand).

- After-sales: Standard Hexagonal Gabion warranties: 5–10 years on coating integrity, lifetime rust-through replacement guarantees (select models).

Customization: Tailored Hexagonal Gabion Options

Recognizing diverse technical and environmental requirements, Hexagonal Gabion solutions can be extensively customized:

- Mesh Aperture: Fine (60x80mm) for landscaping; large (100x120mm) for mass hydraulics.

- Wire Gauge: Core wire 2.0 to 4.0mm; selvedge up to 4.5mm—tuned for load, modularity, and site conditions.

- Coating Schemes: Polymeric (PVC/PE) for aggressive/acidic soils, marine-grade, or infrastructure-critical works.

- Advanced Options: Bio-engineered face mats, prefilled modular units, precision welded lacing for architectural applications, triple-compartment for seismic resistance.

Top Application Scenarios for Hexagonal Gabion

- River & Canal Erosion Control: Allows hydraulic flow while arresting soil loss—used in over 68% river reinforcement projects in EU since 2019.

- Road & Bridge Retaining Walls: Combined with geotextile bases (EN 13249), delivers advanced stability for highways and overpasses.

- Coastal & Marine Works: Gabion breakwaters absorb wave energy, prolonging coastal infrastructure lifespan.

- Mining & Industrial Containment: Superior chemical resistance, ideal for tailings, sediment retention, and hazardous spill barriers.

- Architectural Landscaping: For freestanding walls, green retaining, acoustic enclosures, and urban art installations.

Highlighted Hexagonal Gabion Project Cases & Client Feedback

- Scope: 8,500m bank stabilization, flood defense, gabion lifespan designed for 50+ years.

- Key Data: Used 3x1x1m, 80x100mm mesh, 3.4mm galfan wire, 70,000 tons material output.

- Field Result: Withstood 100-year flood event with no structural failure.

- Scope: 2.1km security fencing and perimeter wall; anti-rust Hexagonal Gabion units with 330g/m² galfan, PVC topcoat.

- Performance Data: 98.7%+ salt spray test (ISO 9227) after 1,160h, minimal corrosion.

- Architect Feedback: “Meshed perfectly with natural desert landscape, rapid onsite assembly.”

- Scope: Submersed retaining wall, offshore cold saltwater, extreme freeze-thaw.

- Material: Galfan + PE coating, 6.5mm heavy selvedge

- Inspector Report: “After 8 years, negligible mesh degradation. Structural integrity > 99%.”

Professional FAQ: Hexagonal Gabion Technical Terminology

Order, Delivery, Quality Commitment & Support

Standard models: 2–3 weeks

Large/Custom batches: 4–6 weeks

Shipping: International by sea/rail; on-site logistics/warehouse options in 24+ countries

- Mesh Integrity: 5–10 years (manufacturer's warranty)

- Coating (on Galfan/PVC lines): Up to 15 years against corrosion/rust-through

- Material Traceability: Full batch number and chemical cert exportable

- Pre-sales engineering guidance and specification recommendation (including FEM simulations)

- On-site supervision, assembly training, and annual inspection (for projects above minimum scale)

- Certified aftersales response guarantees (

References & Further Reading

— Gabions & Structures Forum (Eng-Tips Forum Discussion), 2023

- ASTM (2020). Standard Specification for Double-Twisted Hexagonal Mesh Gabions (ASTM A975-20). [Link]

- EN 10223-3:2013. Steel wire and wire products for fences—Hexagonal steel wire mesh gabions and boxes. [Link]

- MarketsandMarkets (2023). Gabion Market Size, Share & Trends Analysis Report. [Link]

- Proceedings: GEOSYNTHETICS IN CIVIL ENGINEERING, ICE Publishing, Vol. 37 [reference]

- Eng-Tips Forums. Gabion wall permanence in heavy duty marine projects. [Discussion]

This is the last article

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025