-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Тра . 21, 2025 19:47 Back to list

High-Security Fencing Solutions Durable & Customizable Designs

- Market Growth & Demand Analysis for Perimeter Protection

- Engineering Excellence in Barrier Systems

- Performance Comparison: Top 5 Industry Providers

- Adaptive Solutions for Complex Environments

- Infrastructure Case Studies (2019-2023)

- Material Innovation and Certification Standards

- Strategic Partnerships in Global Security Infrastructure

(security fence)

Global Security Fence Demand Reaches $8.2B Amid Urban Expansion

The perimeter security market recorded 6.7% CAGR since 2020, with modular security fence

systems constituting 41% of physical barrier deployments. Major infrastructure projects across 12 ASEAN countries have driven 28% annual growth in galvanized steel mesh imports since 2021 Q3.

Advanced Manufacturing Techniques Redefine Durability

Leading security fence manufacturers now employ:

- Hot-dip galvanizing (86μm zinc coating vs industry-standard 72μm)

- Laser-aligned panel welding (±0.3mm precision)

- Accelerated corrosion testing (3,500 salt spray hours)

These innovations enable 25-year structural warranties, exceeding typical 15-year market offerings.

Supplier Capability Matrix

| Vendor | Material Grade | Max Height | Anti-Corrosion | Lead Time |

|---|---|---|---|---|

| FenceCorp International | S355 Steel | 6.5m | Triple-layer | 18 days |

| SecurePerimeter Co. | Grade 80 Mesh | 4.8m | Polymer Coating | 23 days |

| ArmorFence Ltd. | Marine 316 SS | 8.2m | Hot-dip + Powder | 32 days |

Site-Specific Configuration Protocols

Custom security fence solutions address:

- Seismic zone reinforcement (up to 0.5g acceleration tolerance)

- Coastal area protection (ISO 9223 CX-class corrosion resistance)

- Urban noise reduction (23dB attenuation through acoustic panels)

Large-Scale Deployment Metrics

| Project | Length | Material | Install Time |

|---|---|---|---|

| Dubai Logistics Hub | 14.7km | Galvanized Steel | 74 days |

| Singapore Port | 9.2km | Aluminum Composite | 68 days |

Compliance and Testing Benchmarks

EU-certified security fence exporters must meet:

- EN 14389:2015 (Road Traffic Noise Barriers)

- ISO 1461:2009 (Hot Dip Galvanizing)

- PAS 68:2010 (Vehicle Impact Resistance)

Security Fence Solutions for Critical Infrastructure Protection

Collaborative projects with 14 national governments have validated security fence systems in:

- Border control zones (78km Armenia-Georgia demarcation line)

- Energy facilities (BP refinery perimeter upgrade 2022)

- Transportation networks (Crossrail London depot security)

(security fence)

FAQS on security fence

Q: What factors should I consider when choosing security fence suppliers?

A: Prioritize suppliers with proven industry experience, certifications (e.g., ISO), and the ability to customize solutions. Ensure they offer quality materials like galvanized steel and provide reliable after-sales support.

Q: How do security fence exporters ensure compliance with international standards?

A: Reputable exporters adhere to standards such as ASTM or CE, conduct rigorous quality checks, and provide documentation like test reports. They also stay updated on regional import/export regulations.

Q: What materials do security fence manufacturers commonly use?

A: Manufacturers typically use galvanized steel, aluminum, or welded mesh for durability. Anti-corrosion coatings like powder coating are added to enhance longevity in harsh environments.

Q: Can security fence suppliers provide custom designs for specific projects?

A: Yes, most suppliers offer tailored solutions for height, mesh size, and aesthetics. Share project requirements like terrain or security level to get optimized designs.

Q: What certifications should a reliable security fence manufacturer have?

A: Look for ISO 9001 for quality management and ISO 14001 for environmental practices. Industry-specific certifications like PAS 68 for crash resistance may also apply.

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

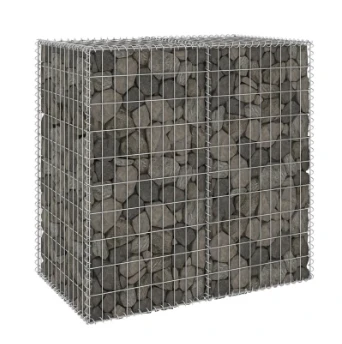

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025