-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Січ . 06, 2025 18:56 Back to list

Welded Wire Mesh

Welded wire mesh, a staple in the construction and industrial sectors, has seen evolving applications that highlight its versatility and durability. As an industry expert with over two decades of experience, I have witnessed firsthand the transformative impact of this product across various applications, solidifying its position as a critical component in modern infrastructure.

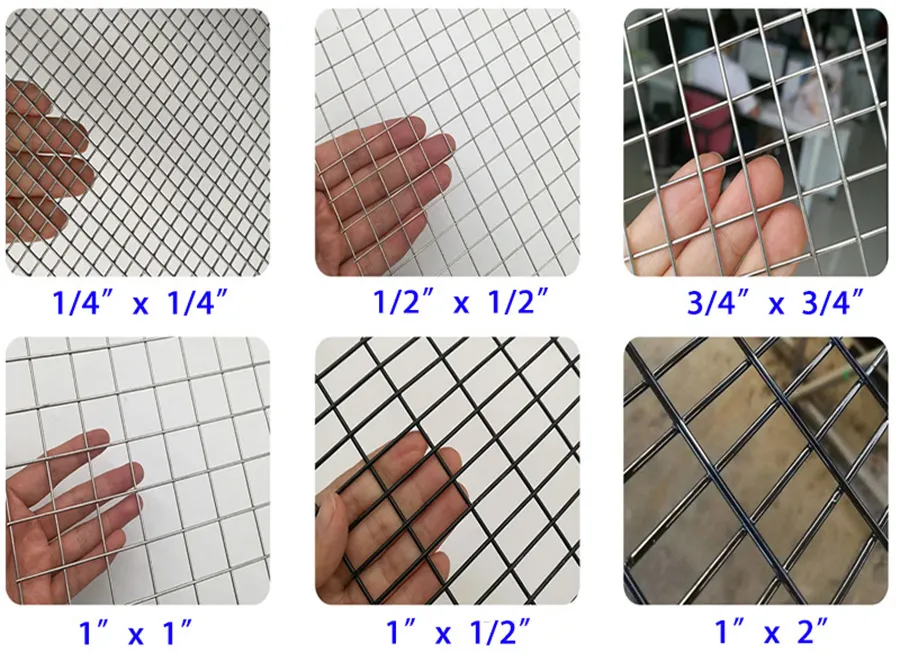

Comprised of intersecting wires that are welded at their joints to form a grid-like pattern, welded wire mesh provides a robust framework that is adaptable for numerous uses. Its varied applications range from reinforcement in concrete structures to serving as barriers for security and safety. The construction industry particularly values its contributions to enhancing structural integrity, reducing cracking, and improving overall longevity of infrastructures.

From an expertise standpoint, understanding the nuances of selecting the appropriate type of welded wire mesh is crucial. Factors such as wire gauge, mesh size, and the type of coating impact its performance in distinct environments. For example, galvanized welded wire mesh offers enhanced corrosion resistance, making it suitable for outdoor or humid applications. Conversely, stainless steel welded wire mesh stands out for environments requiring high levels of cleanliness and structural strength, commonly seen in food processing or medical facilities.

Authoritativeness in the field of welded wire mesh production and usage is established through adherence to industry standards and certifications. Trusted manufacturers ensure their products undergo rigorous testing to meet ASTM and ISO certifications, providing assurance of quality and performance. Collaboration with certified vendors can also contribute significantly to project outcomes, offering design insights and bespoke solutions that standard products may not address.

welded wire mesh

Building trustworthiness in welded wire mesh applications hinges on transparent communication about product capabilities and limitations. Educating clients on proper installation techniques, maintenance practices, and potential environmental impacts further solidifies trust. For instance, employing proper anchoring methods and accounting for thermal expansion can prevent structural failures, ensuring long-term efficacy of the mesh in construction projects.

Real-world experiences underscore the importance of adaptability in the use of welded wire mesh. In urban development projects, for instance, its use in precast wall panels not only accelerates construction timelines but also enhances thermal insulation and soundproofing. Similarly, its function as a security measure in public spaces provides safety without compromising on aesthetics, offering a balance of form and function that appeals to architects and urban planners alike.

One innovative development is the integration of welded wire mesh within smart city initiatives. By embedding sensors within the mesh, it becomes possible to monitor structural integrity in real-time, providing data-driven insights for maintenance and safety protocols. Such advancements demonstrate the mesh’s evolving role from a mere structural component to an integral part of intelligent infrastructure systems.

In conclusion, welded wire mesh remains an indispensable asset in the realms of construction and industrial applications. Its enduring relevance is a testament to its adaptability, strength, and the continuous advancements made within the industry to meet emerging needs. Whether through enhancing safety, improving structural integrity, or contributing to sustainable building practices, welded wire mesh is a product whose capabilities and contributions are both necessary and valued in the ever-evolving landscape of modern engineering.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025