-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Лис . 04, 2024 20:32 Back to list

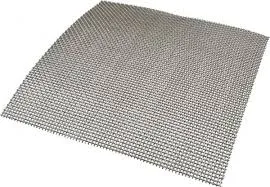

wire mesh for concrete manufacturers

Understanding Wire Mesh for Concrete Manufacturing A Comprehensive Guide

Wire mesh, also known as welded wire fabric, plays a critical role in the field of concrete manufacturing. It enhances the structural integrity of concrete, offering reinforcement that can withstand various stresses throughout its lifespan. This article delves into the importance, applications, and types of wire mesh used in concrete manufacturing, along with insights for manufacturers.

Importance of Wire Mesh in Concrete

Concrete, while strong in compression, is relatively weak in tension. This vulnerability can lead to cracking and structural failure if not adequately addressed. Wire mesh provides tension reinforcement, distributing loads more evenly across the concrete structure. By integrating wire mesh into concrete, manufacturers can significantly improve durability, reduce the risk of cracking, and prolong the service life of the structure.

Wire mesh is also essential in controlling shrinkage cracks that can occur during the curing process. Moreover, it aids in improving the overall stability of slabs, walls, and other concrete elements, ensuring they can endure the stresses encountered during their use.

Applications of Wire Mesh

Wire mesh is widely used in various concrete applications. Some of the most common include

1. Reinforced Concrete Slabs Wire mesh is commonly utilized in the construction of floors, driveways, and foundations. It helps distribute the load and prevents cracks from developing.

2. Walls and Partitions In walls, wire mesh enhances strength and stability, making it a preferred choice for residential and commercial structures.

4. Precast Concrete Products Wire mesh is integral to precast concrete elements such as beams, columns, and panels, providing the necessary reinforcement for strength and stability.

wire mesh for concrete manufacturers

Types of Wire Mesh

Wire mesh for concrete comes in various types, each suited to specific applications. These include

1. Welded Wire Fabric (WWF) This is the most common type of wire mesh used in concrete reinforcement. It consists of longitudinal and transverse wires welded together at regular intervals, creating a grid-like pattern. WWF is versatile and can be customized for different sizes depending on project requirements.

2. Fiber-Reinforced Mesh This type incorporates synthetic fibers into the concrete mix, enhancing its tensile strength and reducing shrinkage cracks. While it serves a similar purpose as traditional wire mesh, it is often used in lighter applications.

3. Expanded Metal Mesh Made by cutting and stretching sheet metal, expanded metal mesh is used in situations requiring additional surface area, such as for bonding with the concrete.

4. Chain Link and Barbed Wire Used less frequently in structural applications, these types can be found in certain security applications and fencing.

Choosing the Right Wire Mesh

For manufacturers, selecting the right type of wire mesh is crucial to the success of a concrete project. Factors to consider include the specific application, load requirements, environmental conditions, and local building codes. Engaging with reputable suppliers ensures access to high-quality materials, which can significantly impact the overall performance of the concrete.

Conclusion

Wire mesh is an indispensable component of concrete manufacturing, providing essential reinforcement that enhances the strength and durability of various structures. By understanding the types and applications of wire mesh, manufacturers can make informed choices that lead to improved outcomes for their concrete products. As the construction industry continues to evolve, the use of innovative materials like wire mesh will undoubtedly play a vital role in shaping resilient and sustainable built environments.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025