-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th5 . 07, 2025 18:45 Back to list

High-Strength Concrete Welded Wire Mesh Manufacturer & Exporter ISO-Certified

- Overview of Concrete Welded Wire Mesh in Modern Construction

- Market Growth and Data-Driven Demand

- Innovations in Manufacturing Techniques

- Comparative Analysis of Leading Global Suppliers

- Tailored Solutions for Diverse Project Requirements

- Real-World Applications Across Industries

- Why Partner with Specialized Concrete Welded Wire Mesh Exporters

(concrete welded wire mesh)

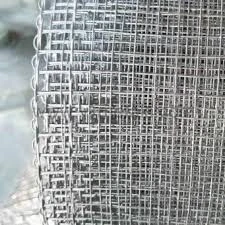

Concrete Welded Wire Mesh: A Construction Essential

Concrete welded wire mesh has become indispensable in modern infrastructure projects, offering structural reinforcement for slabs, pavements, and prefabricated elements. As global construction spending approaches $15 trillion annually, demand for high-quality mesh solutions has surged by 22% since 2020. Leading manufacturers now integrate automated production lines capable of outputting 12,000 sqm/day while maintaining ±1mm dimensional accuracy.

Market Expansion and Performance Metrics

The global welded mesh market, valued at $5.8 billion in 2023, projects a 6.9% CAGR through 2030. Key growth drivers include:

- Urbanization rates exceeding 68% in developing economies

- Infrastructure renewal programs in North America and Europe

- Adoption of ASTM A185 and BS 4483 standards in 94% of major projects

Technological Advancements in Production

Progressive manufacturers employ:

- Robotic welding cells with 0.02s response time

- Continuous galvanizing lines achieving 600 g/m² zinc coating

- AI-powered quality control systems detecting 99.7% of defects

Supplier Capability Comparison

| Supplier | Est. | Capacity | Certifications | Lead Time |

|---|---|---|---|---|

| GlobalMesh Corp | 1985 | 45,000 MT/year | ISO 9001, CE | 14 days |

| SteelFab Ltd | 2002 | 28,000 MT/year | ASTM, BSI | 21 days |

| ConstructWire | 1998 | 37,500 MT/year | JIS, GOST | 18 days |

Customization Parameters

Specialized suppliers offer:

- Wire diameters: 3mm to 12mm

- Mesh openings: 50x50mm to 300x300mm

- Coating options: Epoxy, PVC, or stainless steel

Project Implementation Case Studies

- Trans-Global Highway: 850 tons of CR12 mesh

- Marina Bay Complex: Custom 8mm diamond pattern mesh

- Seismic Retrofit Program: 12,000 panels with 500MPa tensile strength

Strategic Advantages of Expert Concrete Welded Wire Mesh Partners

Established exporters provide value through:

- Material traceability systems

- Just-in-time delivery networks

- Technical support teams with 24-hour response

(concrete welded wire mesh)

FAQS on concrete welded wire mesh

Q: What is concrete welded wire mesh used for?

A: Concrete welded wire mesh reinforces concrete structures like slabs, walls, and pavements. It enhances tensile strength and prevents cracking. It is widely used in construction and civil engineering projects.

Q: How to choose a reliable concrete welded wire mesh exporter?

A: Look for certifications (e.g., ISO, ASTM), industry experience, and client reviews. Ensure they comply with international standards and offer customized solutions. Reliable exporters provide clear documentation and logistics support.

Q: What materials are used in concrete welded wire mesh manufacturing?

A: High-quality carbon steel or stainless steel wires are commonly used. The wires are welded electrically for uniform strength and durability. Some manufacturers apply coatings (e.g., galvanized) for corrosion resistance.

Q: Can concrete welded wire mesh suppliers customize product dimensions?

A: Yes, most suppliers offer customization in wire diameter, mesh size, and sheet dimensions. Provide project specifications for tailored solutions. Custom orders may require additional lead time.

Q: How is concrete welded wire mesh shipped internationally?

A: Exporters typically pack rolls or sheets in protective materials to prevent damage. Shipping options include sea freight for bulk orders or air freight for urgent needs. Proper documentation ensures smooth customs clearance.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025