-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th11 . 01, 2024 11:46 Back to list

Crimped Wire Mesh Production Facilities and Their Applications in Various Industries

The Growing Market of Crimped Mesh Factories

In recent years, the demand for crimped mesh has surged, leading to the establishment of numerous crimped mesh factories across the globe. Crimped mesh, characterized by its unique wavy design, has diverse applications in various industries including construction, agriculture, and mining. This article explores the significance of crimped mesh factories, their manufacturing processes, and their considerable contributions to the economy.

Crimped mesh is primarily made from high-quality wire materials, which are processed to achieve the desired crimped pattern. The production process typically involves the weaving of wire into a mesh format, followed by crimping, which is the act of altering the wire's form to create a series of undulating waves. This crimped structure enhances the mesh's strength and flexibility, making it ideal for a plethora of uses. For instance, in construction, crimped mesh is often used as reinforcement in concrete, improving the structural integrity of buildings and pavements.

The establishment of crimped mesh factories has been driven by the increasing need for specialized materials that can withstand harsh environmental conditions while providing durability and aesthetic value. These factories not only serve local markets but also cater to international demands. This globalization has led to many factories investing in advanced machinery and technology to streamline their production processes and improve product quality.

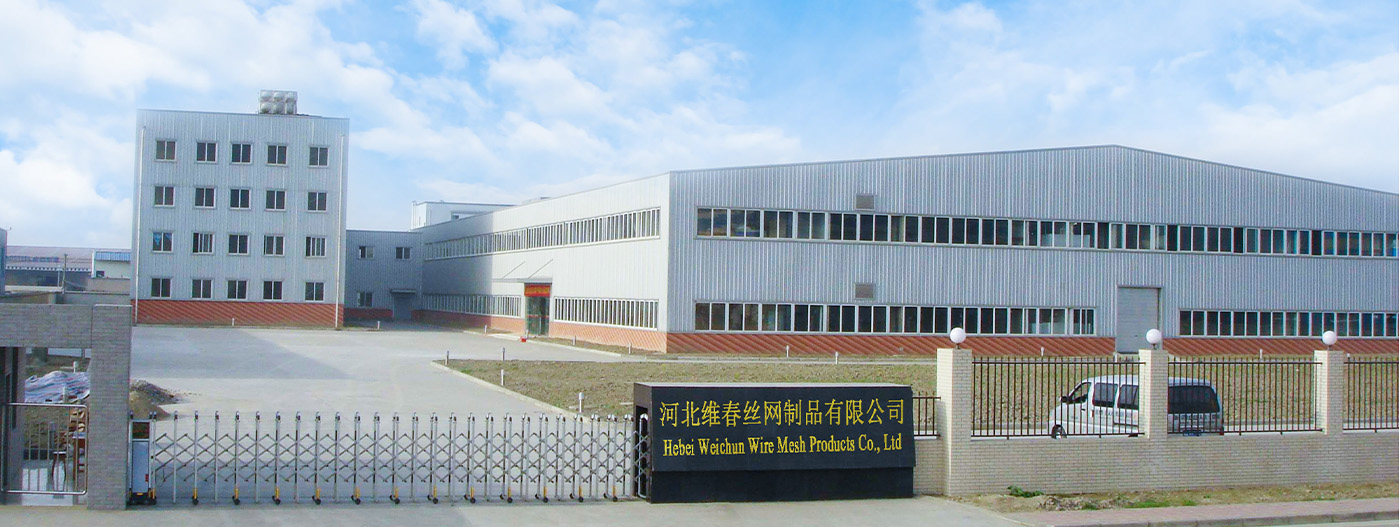

crimped mesh factories

Furthermore, crimped mesh factories contribute significantly to local economies by creating jobs and fostering small businesses. The labor-intensive nature of the crimping process necessitates a skilled workforce, thus providing employment opportunities in communities where these factories are located. Additionally, ancillary businesses also benefit from the establishment of these factories, including suppliers of raw materials and distributors of finished products.

Moreover, crimped mesh has applications beyond industry. In agriculture, it can be used to create protective barriers for crops, safeguarding them from pests and adverse weather. In the realm of art and design, crimped mesh has found its way into creative installations and architectural features, reflecting its versatility and appeal.

As the market for crimped mesh continues to expand, it faces challenges such as competition from alternative materials and the need for sustainable practices. However, many factories are adapting by embracing eco-friendly methods and materials, thus addressing environmental concerns while maintaining efficiency.

In conclusion, crimped mesh factories play a vital role in meeting the intricate demands of various industries. Their innovative production techniques not only enhance the quality of crimped mesh but also support economic growth through job creation and local investment. As the world increasingly turns to specialized materials, the future of crimped mesh factories looks promising, driven by both industrial needs and creative applications.

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025