-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th10 . 16, 2024 17:42 Back to list

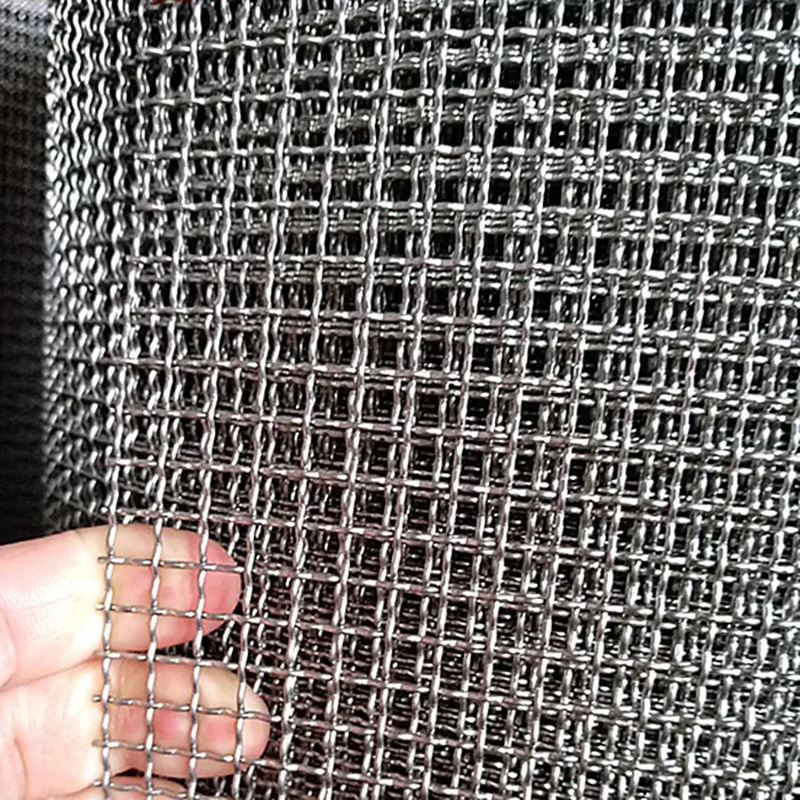

custom 10 gauge wire mesh

Custom 2010 Gauge Wire Mesh Versatility and Applications

Wire mesh has long been a staple in various industries due to its strength, durability, and versatility. Among the various specifications available, custom 2010 gauge wire mesh stands out for its unique properties, making it an ideal choice for a wide range of applications.

Understanding the Basics

Gauge refers to the thickness of the wire used to create the mesh. A 2010 gauge wire mesh indicates that the wire has a diameter of approximately 0.036 inches or 0.914 mm. This medium thickness strikes a balance between strength and flexibility, allowing the mesh to maintain its integrity under pressure while still being manageable for various fabrication processes.

Key Features

One of the primary advantages of custom 2010 gauge wire mesh is its adaptability. Manufacturers can produce it in various materials, including stainless steel, aluminum, and carbon steel. This allows businesses to choose a mesh that best suits their specific operational environments. For example, stainless steel options are excellent for corrosive settings, whereas aluminum meshes are lightweight and highly resistant to rust.

Moreover, custom wire mesh can be tailored in terms of aperture size, opening patterns, and weave styles. This customization ensures that the finished product meets the precise requirements of the application it is intended for, whether that’s filtration, safety, or architectural purposes.

Applications

custom 10 gauge wire mesh

The versatility of custom 2010 gauge wire mesh means it finds applications across numerous sectors. Here are a few notable uses

1. Industrial Filtration In manufacturing settings, wire mesh is frequently employed for filtration. Custom 2010 gauge mesh can efficiently separate particles from liquids and gases, making it essential in chemical processing, water treatment, and food production industries.

2. Safety and Security The strength of this gauge mesh makes it an ideal option for security fencing. It can act as a barrier to deter intruders while ensuring visibility for monitoring purposes. Additionally, it can be utilized in window grills and safety guards for machinery.

3. Construction and Architecture In construction, wire mesh is a critical component in reinforcing concrete structures. Custom 2010 gauge mesh enhances the tensile strength of concrete, allowing for safer building practices. Architects also leverage its aesthetic qualities, using it in decorative screens and facades that provide both form and function.

4. Agriculture Farmers and agricultural businesses use wire mesh for various purposes, including fencing for livestock, creating enclosures for plants, and as protective covers for crops from pests and harsh weather conditions.

Conclusion

Custom 2010 gauge wire mesh is an excellent example of how a simple product can serve a multitude of functions across different industries. Its combination of strength, versatility, and customization options makes it invaluable for applications ranging from industrial filtration to architectural design. Whether you are in manufacturing, construction, or agriculture, investing in quality custom wire mesh can enhance operational efficiency and safety, making it a worthy consideration for your next project. As industries continue to evolve, the demand for such tailored solutions will likely grow, highlighting the importance of innovation in wire mesh manufacturing.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025