-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th2 . 14, 2025 20:35 Back to list

Galvanized/PVC Coated Hexagonal Wire Mesh

Custom galvanized steel wire is a product that represents an intersection of industrial need and engineering excellence. Understanding its unique properties and applications allows businesses and consumers alike to make informed decisions, resulting in better performance and longer-lasting solutions for various projects.

Experience in working with galvanized steel wire underscores its strengths. Professionals often cite its longevity and ability to mitigate issues such as corrosion fatigue and stress corrosion cracking. This experience leads to insights that further improve product offerings, creating a cycle of enhancement that continually pushes the boundaries of what galvanized wire can achieve. The trustworthiness of custom galvanized steel wire is further emphasized by the transparency of manufacturers who invite audits and inspections. Clients are increasingly welcomed into facilities to understand the wire’s lifecycle from raw material to finished product. This openness builds trust through visibility and demonstrates a commitment to quality that extends beyond the mere transactional. Innovations in the industry are continually revolutionizing the possibilities of custom galvanized steel wire. From the introduction of eco-friendly galvinization methods that reduce environmental impact to new alloy combinations that offer breathtaking strengths and capabilities, the commitment to innovation showcases the industry's forward-thinking approach. Companies investing in research and development allow them to offer cutting-edge materials, such as those with enhanced conductivity for specific electrical applications, or designed with higher tensile strengths for advanced construction projects. As digital transformation takes hold globally, digital platforms enhance the visibility and accessibility of custom galvanized steel wire. Online configurators enable potential clients to design their wire according to precise specifications, checking their dimensions and coating requirements against a library of past projects. This digital engagement aligns with the modern buyer's demand for quick, accurate, and reliable information. In conclusion, custom galvanized steel wire is not just another material on the market; it's a testament to specialized expertise, engineering excellence, and a genuine understanding of consumer needs. For stakeholders utilizing this material, whether it’s the construction supervisor ensuring the safety and longevity of a new build or the agricultural manager replacing worn-out fencing, the reliability and customization available in galvanized steel wire make it an investment that promises remarkable returns. The industry’s commitment to quality, innovation, and transparency further consolidates trust and positions custom galvanized steel wire as a leading choice for projects demanding robust, adaptable, and long-lasting materials.

Experience in working with galvanized steel wire underscores its strengths. Professionals often cite its longevity and ability to mitigate issues such as corrosion fatigue and stress corrosion cracking. This experience leads to insights that further improve product offerings, creating a cycle of enhancement that continually pushes the boundaries of what galvanized wire can achieve. The trustworthiness of custom galvanized steel wire is further emphasized by the transparency of manufacturers who invite audits and inspections. Clients are increasingly welcomed into facilities to understand the wire’s lifecycle from raw material to finished product. This openness builds trust through visibility and demonstrates a commitment to quality that extends beyond the mere transactional. Innovations in the industry are continually revolutionizing the possibilities of custom galvanized steel wire. From the introduction of eco-friendly galvinization methods that reduce environmental impact to new alloy combinations that offer breathtaking strengths and capabilities, the commitment to innovation showcases the industry's forward-thinking approach. Companies investing in research and development allow them to offer cutting-edge materials, such as those with enhanced conductivity for specific electrical applications, or designed with higher tensile strengths for advanced construction projects. As digital transformation takes hold globally, digital platforms enhance the visibility and accessibility of custom galvanized steel wire. Online configurators enable potential clients to design their wire according to precise specifications, checking their dimensions and coating requirements against a library of past projects. This digital engagement aligns with the modern buyer's demand for quick, accurate, and reliable information. In conclusion, custom galvanized steel wire is not just another material on the market; it's a testament to specialized expertise, engineering excellence, and a genuine understanding of consumer needs. For stakeholders utilizing this material, whether it’s the construction supervisor ensuring the safety and longevity of a new build or the agricultural manager replacing worn-out fencing, the reliability and customization available in galvanized steel wire make it an investment that promises remarkable returns. The industry’s commitment to quality, innovation, and transparency further consolidates trust and positions custom galvanized steel wire as a leading choice for projects demanding robust, adaptable, and long-lasting materials.

Latest news

-

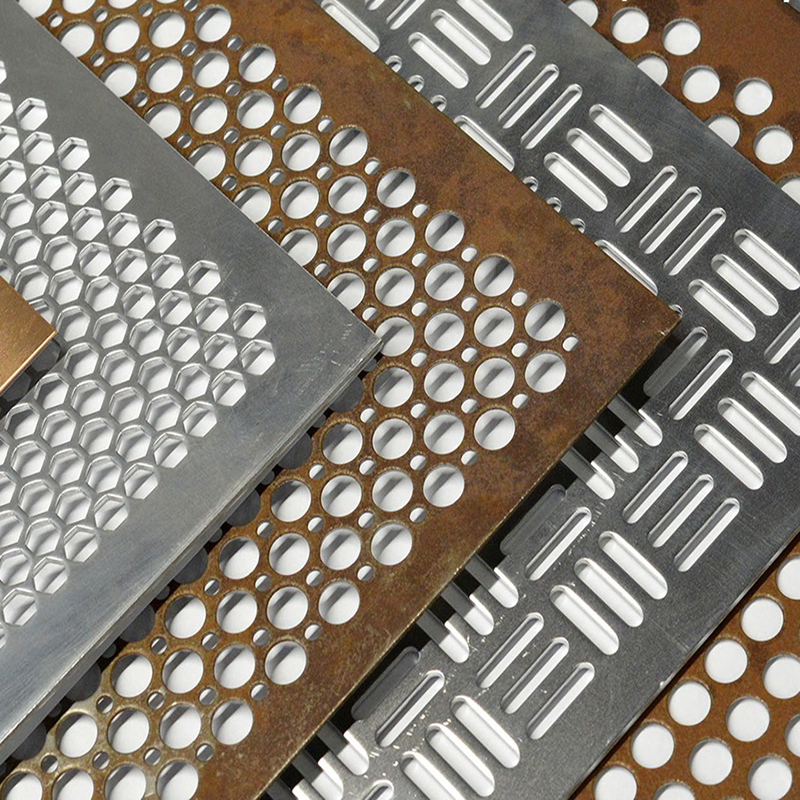

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025