-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th11 . 23, 2024 02:26 Back to list

custom razor wire prices

Understanding Custom Razor Wire Prices

Razor wire has gained popularity in various applications, particularly in security and perimeter fencing. Known for its sharp edges and high deterrent value, it is engineered to provide an effective barrier against intruders. However, when it comes to obtaining custom razor wire, understanding the pricing structure is crucial for stakeholders in security, construction, and landscaping.

Factors Influencing Custom Razor Wire Prices

Several factors influence the prices of custom razor wire, and being aware of these can help buyers make informed decisions

. The key components include1. Material Type The primary material used in razor wire production is galvanized steel, which offers corrosion resistance and durability. Stainless steel is another option, providing additional rust resistance but at a higher cost. The choice between these materials directly impacts the pricing.

2. Gauge and Diameter The thickness and diameter of the wire also play a significant role in the overall cost. Thicker wires are more expensive because they require more raw materials. Additionally, the type of blades (conical, barbed, etc.) affects the cost. Custom configurations can lead to further variations in pricing.

3. Length and Configuration Custom razor wire is often configured to meet specific site needs. Prices are influenced by the length and shape of the wire. For instance, spiral coils or concertina types generally cost more due to the additional processing required. Measurements taken on the site can lead to unique configurations, impacting overall pricing.

4. Manufacturing Process The method used to manufacture the razor wire, whether it be machine-made or handcrafted, can affect pricing. Machine production tends to be more cost-efficient for larger orders, while handcrafted options, which offer bespoke features, usually come at a premium.

custom razor wire prices

5. Order Quantity Bulk purchases generally lead to lower per-unit costs. Suppliers may offer discounts on larger orders, thus encouraging customers to buy in larger quantities. Conversely, smaller orders may incur higher costs due to fixed setup and delivery charges.

6. Shipping and Handling Depending on the supplier's location, shipping costs can significantly affect the final price of custom razor wire. Potential buyers must factor in shipping when comparing quotes from different suppliers. Additionally, the loading and unloading logistics may introduce extra handling fees.

7. Installation Costs Prices for razor wire can also vary based on installation requirements. While some customers might prefer a do-it-yourself approach, hiring professionals to install custom razor wire can increase the overall expense. The complexity of the installation, site conditions, and local labor rates all impact the final cost.

Seasonal Fluctuations and Market Trends

Like many other construction materials, the price of custom razor wire may fluctuate due to market trends, seasonal demand, and global steel prices. During periods of high demand, such as post-natural disasters or during increased security threats, prices can spike. Economic factors such as tariffs on imported steel can also lead to significant price changes.

Conclusion

In summary, various factors influence the pricing of custom razor wire, including material type, dimensions, manufacturing methods, and order quantities. Understanding these aspects can help buyers navigate the complexities of procurement effectively. By making informed choices and considering potential installation costs, customers can secure the best value for their investment in custom razor wire, ensuring enhanced security for their premises. With the right approach, clients can leverage custom solutions tailored to their unique security needs while maintaining budgetary constraints.

-

Custom Square Wire Mesh - High Quality, Wholesale Supply

NewsAug.15,2025

-

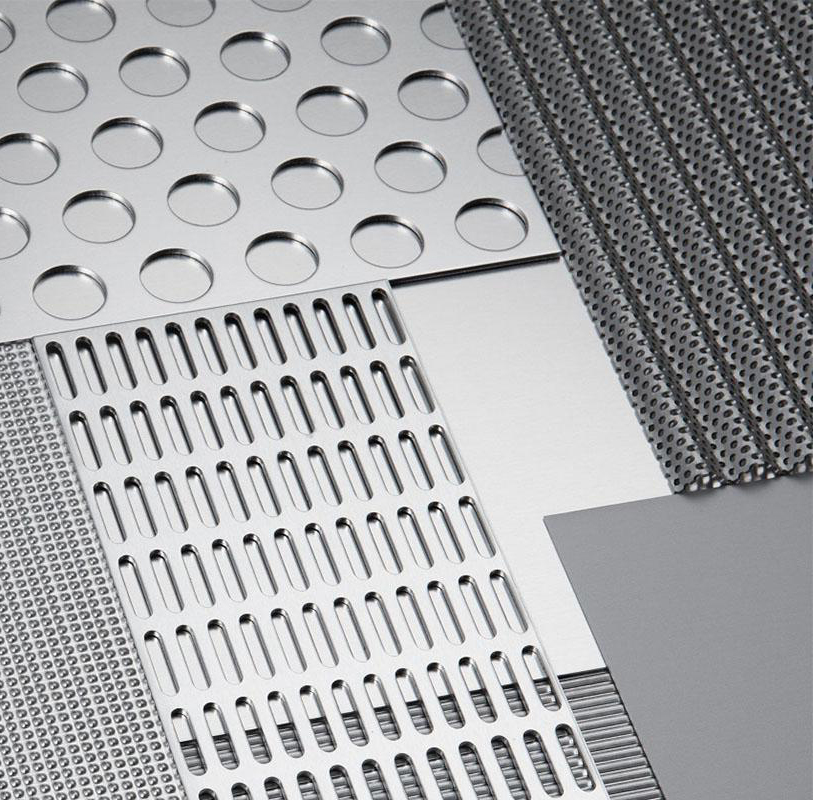

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025

-

3D Curved Welded Mesh Fence: Enhanced Security & Durability

NewsAug.12,2025

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025