-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th8 . 11, 2025 10:20 Back to list

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

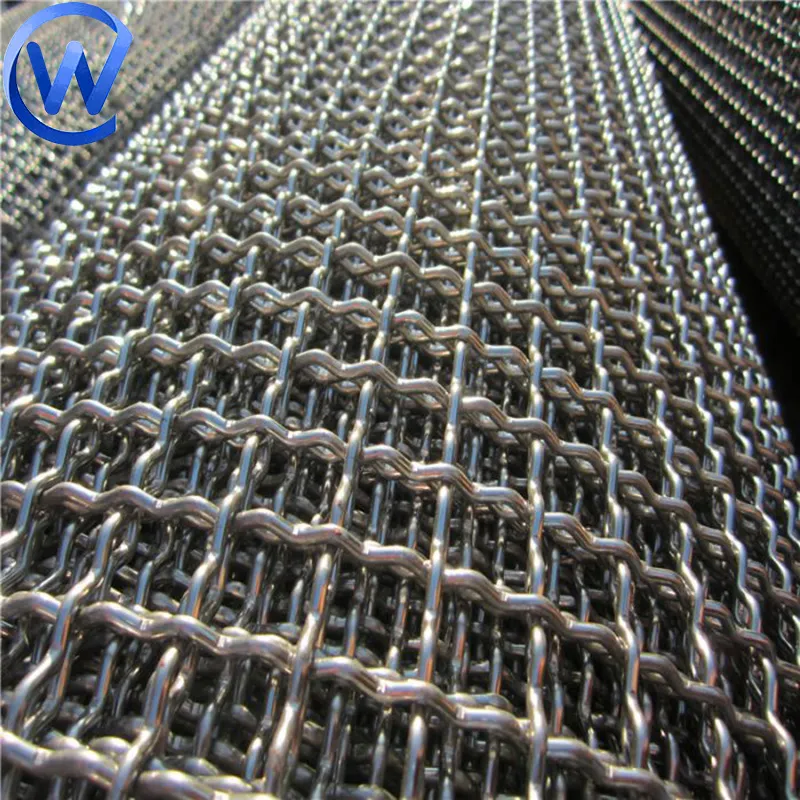

Crimped Wire Mesh: A Foundation for Industrial Excellence and Innovation

In the realm of industrial materials, crimped wire mesh stands as a testament to engineering precision and versatile functionality. This specialized mesh, characterized by its pre-crimped wires, offers superior structural integrity, dimensional stability, and precise opening sizes, making it an indispensable component across a multitude of sectors. The global market for wire mesh products is experiencing steady growth, driven by increasing demand in construction, mining, filtration, and architectural design. Key trends indicate a rising preference for durable, corrosion-resistant materials and custom solutions that meet stringent performance criteria. Businesses are increasingly seeking partners who can deliver not just a product, but a reliable solution that contributes to operational efficiency and safety, aligning with the evolving demands for sustainable and robust material solutions in an ever-complex industrial landscape.

The demand for high-performance meshes is particularly pronounced in industries requiring fine-grade separation, robust protective barriers, and aesthetic architectural elements. This includes sectors such as aggregates and mining, where precise screening is critical; food processing, necessitating hygienic and durable components; and security fencing, demanding unwavering strength. The unique characteristics of crimped wire mesh, including its inherent rigidity and consistent aperture, address these complex requirements, often outperforming traditional woven meshes in applications demanding higher load-bearing capacity or specific filtration properties. As industries evolve, so does the sophistication of mesh applications, driving innovation in material science and manufacturing processes to achieve even greater levels of performance and longevity.

The Meticulous Manufacturing Process of Crimped Wire Mesh

Precision Engineering from Wire to Weave

The production of crimped wire mesh is a sophisticated process demanding precision at every stage, ensuring the final product meets stringent performance and durability requirements. It commences with the selection of high-quality raw materials, typically stainless steel (304, 316, 316L), galvanized steel, carbon steel, or even specialty alloys, chosen based on the intended application's demands for corrosion resistance, strength, and temperature tolerance. The wire drawing process reduces the raw wire to the specified diameter, maintaining tight tolerances. Following this, the critical crimping stage involves specialized machinery that precisely bends the individual wires into a corrugated pattern. These pre-crimped wires are then interwoven on high-speed looms, creating a robust and stable mesh structure where each wire interlocks perfectly, preventing shifting or deformation under stress. This unique weaving method, distinct from plain or twill weaves, significantly enhances the mesh's rigidity and load-bearing capacity, a crucial factor in heavy-duty industrial applications.

Quality control is paramount throughout the manufacturing cycle for crimped wire mesh. From the initial material inspection to final product verification, adherence to international standards such as ISO 9001, ASTM (American Society for Testing and Materials), and ANSI (American National Standards Institute) is strictly maintained. Inspections cover wire diameter consistency, crimp pattern uniformity, opening size accuracy, and overall structural integrity. For applications like those in the petrochemical or food processing industries, material traceability and compliance with specific FDA or NACE standards are also verified. This rigorous quality assurance regimen ensures that each sheet of crimped wire mesh delivered exhibits exceptional longevity, often exceeding 10-15 years in typical industrial environments, while providing optimal performance in filtration, screening, and structural support roles. Its inherent resistance to corrosion, especially in the case of galvanized crimped wire mesh or stainless steel variants, makes it ideal for harsh environments, contributing to energy savings by reducing maintenance and replacement costs.

Technical Specifications and Performance Parameters

Ensuring Precision and Durability for Critical Applications

Understanding the technical parameters of crimped wire mesh is crucial for selecting the optimal product for specific industrial demands. These parameters define the mesh's physical properties and dictate its performance in diverse applications, from high-precision filtration to heavy-duty screening. The primary specifications include wire diameter, which directly impacts strength and flow rate; opening size (aperture), determining the size of particles that can pass through; and weave type, which includes standard crimp, intermediate crimp, double crimp, and lock crimp, each offering distinct rigidity and stability characteristics. Material composition, such as different grades of stainless steel, directly influences resistance to corrosion, heat, and chemical exposure, crucial for longevity in harsh operating environments.

For instance, a finer mesh with a smaller wire diameter might be suitable for precise filtration in pharmaceutical processes, whereas a heavier gauge, larger opening mesh would be ideal for aggregate screening in mining operations due to its superior wear resistance and capacity. The tensile strength of the wire material is also a critical factor, indicating the maximum stress the mesh can withstand before breaking. Manufacturers often provide detailed data on these parameters, allowing engineers and procurement specialists to specify high quality crimped wire mesh that aligns perfectly with their operational requirements, ensuring both efficiency and safety.

| Parameter | Typical Range/Options | Significance |

|---|---|---|

| Material | Stainless Steel (304, 316, 316L), Galvanized Steel, Carbon Steel, Copper, Brass | Corrosion resistance, strength, conductivity, temperature tolerance. |

| Wire Diameter | 0.7mm to 6.0mm (0.027" to 0.236") | Overall strength, load-bearing capacity, abrasion resistance. |

| Opening Size (Aperture) | 1.0mm to 100mm (0.039" to 4") | Filtration accuracy, particle sizing, light/air flow. |

| Mesh Count | 1 to 100 mesh per inch (MPI) | Number of openings per linear inch; inversely related to opening size. |

| Crimp Type | Plain crimp, Intermediate crimp, Double crimp, Lock crimp | Mesh rigidity, stability, aesthetic appearance. |

| Tensile Strength | Varies significantly by material and wire diameter (e.g., 520-690 MPa for SS304) | Resistance to breaking under tension; critical for structural applications. |

Diverse Applications Across Key Industries

Versatility Meeting Industrial Demands

The robust and stable nature of crimped wire mesh lends itself to an extensive array of applications across diverse industrial sectors. In the mining and quarrying industry, it is indispensable for sizing and grading raw materials like aggregates, coal, and minerals, ensuring efficient separation and processing. Its durability withstands harsh abrasive conditions, making it superior for vibratory screens. Within the construction sector, this mesh serves as robust security fencing, infill panels for guardrails, and even architectural facades, where its aesthetic appeal combines with its structural integrity. For water treatment and environmental applications, galvanized crimped wire mesh or stainless steel variants provide durable filtration elements for pre-screening large particulates in wastewater or industrial effluents, offering excellent corrosion resistance even in chemically aggressive environments. This contributes directly to prolonged equipment life and reduced operational downtime, embodying both reliability and cost-efficiency.

Beyond these, crimped wire mesh finds critical roles in agriculture for animal enclosures and grain storage, in food processing for drying and cooling trays, and in various manufacturing processes for parts washing and heat treatment baskets. Its ability to maintain precise aperture sizes under stress makes it ideal for precision filtration in petrochemical industries, while its inherent strength offers reliable protection as machine guards in industrial plants. The versatility of this material, coupled with its proven performance, underscores why it remains a fundamental choice for engineers and designers seeking reliable, long-lasting solutions for demanding operational environments, consistently delivering superior results where other materials may falter.

Customization Capabilities and Bespoke Solutions

Tailored to Your Exact Specifications

Recognizing that standard products may not always meet the unique demands of every industrial application, leading crimped wire mesh manufacturers and crimped wire mesh suppliers offer extensive customization capabilities. This allows businesses to procure custom crimped wire mesh tailored precisely to their project specifications. Customization options typically include variations in material type (e.g., specific grades of stainless steel for extreme temperatures or aggressive chemicals), wire diameter, opening size, and mesh dimensions. Furthermore, specialized crimp styles can be engineered to achieve specific rigidity or aesthetic characteristics, and various edge treatments or fabrication processes like welding, cutting, and bending can be applied to create finished components ready for installation.

The process for obtaining custom crimped wire mesh usually involves a detailed consultation to understand the application environment, performance requirements, and any specific industry compliance needs. Experienced engineering teams then translate these requirements into precise technical drawings and material specifications, ensuring the custom mesh will perform optimally. This bespoke approach not only guarantees perfect fit and function but also often leads to improved system efficiency, reduced material waste, and extended service life, proving a cost-effective strategy for complex projects. Collaborating with a crimped wire mesh factory that possesses advanced manufacturing capabilities and a commitment to precision is vital for successful custom projects.

Choosing the Right Partner: Manufacturer Comparison and Quality Assurance

Ensuring Trust and Reliability in Your Supply Chain

Selecting the ideal crimped wire mesh exporter or crimped wire mesh factory is paramount for ensuring consistent product quality, timely delivery, and competitive pricing. Key considerations include the manufacturer's operational history, evidenced by years of service and a robust portfolio of successful projects. Certifications like ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System) are non-negotiable, demonstrating a commitment to international quality and sustainability standards. A reputable supplier will also possess comprehensive in-house quality control (QC) procedures, spanning raw material inspection, in-process monitoring, and final product testing, ensuring every batch of wholesale crimped wire mesh adheres to strict performance criteria.

Beyond certifications, assess the supplier's technical support capabilities, including their ability to offer expert advice on material selection, design optimization, and custom fabrication. A strong R&D department signals a commitment to innovation and problem-solving, capable of developing new solutions for evolving industry challenges. Client testimonials and case studies offer invaluable insights into past performance and customer satisfaction. Furthermore, transparency in their manufacturing processes and a clear warranty policy underscore trustworthiness. For businesses requiring large volumes or specialized designs, partnering with a crimped wire mesh factory with a proven track record for delivering high quality crimped wire mesh consistently, on time, and within budget, is crucial for long-term operational success.

Case Studies & Client Success

Real-World Impact of High-Quality Crimped Wire Mesh

Case Study 1: Enhanced Screening in Aggregate Production

A leading quarry operator faced frequent breakdowns and premature wear of their vibratory screen media, leading to significant downtime and reduced output. After consulting with a specialized crimped wire mesh supplier, they implemented heavy-duty high quality crimped wire mesh with a specialized lock crimp design, manufactured from abrasion-resistant manganese steel. The result was a 40% increase in screen lifespan, a 15% reduction in maintenance costs, and improved consistency in aggregate sizing, directly impacting their operational efficiency and profitability. This demonstrated the tangible benefits of choosing the correct mesh type and material for demanding applications.

Case Study 2: Architectural Facade for Urban Development

An architectural firm designing a modern commercial complex sought a durable yet aesthetically pleasing material for building facades and sun shading. They partnered with a crimped wire mesh manufacturer to develop custom crimped wire mesh panels made from architectural-grade stainless steel with a unique intermediate crimp pattern. The panels provided excellent solar shading, reducing internal cooling loads, while offering a contemporary visual appeal that allowed natural light and airflow. The project received commendation for its innovative use of materials, showcasing the versatility of crimped wire mesh beyond traditional industrial uses.

Frequently Asked Questions (FAQ) & Support

Addressing Your Concerns with Transparency

Q1: What are the primary advantages of crimped wire mesh over plain woven mesh?

A1: Crimped wire mesh offers superior structural stability due to its pre-crimped wires that lock into place, preventing movement. This results in more precise and consistent opening sizes, better resistance to vibration and heavy loads, and enhanced durability, making it ideal for screening, sizing, and applications where stability is critical.

Q2: How do I choose the correct material for my crimped wire mesh application?

A2: Material selection depends on the operating environment. For corrosive or high-temperature conditions, stainless steel (e.g., 304, 316, 316L) is recommended. Galvanized crimped wire mesh offers excellent corrosion resistance for outdoor or damp environments at a more economical price point. Carbon steel is suitable for general industrial applications where strength and cost are primary concerns. Consulting with a crimped wire mesh supplier can help determine the optimal material.

Q3: What is the typical delivery cycle for custom crimped wire mesh orders?

A3: Delivery cycles for custom crimped wire mesh vary based on complexity, material availability, and order volume. Typically, standard custom orders can be fulfilled within 2-4 weeks after design approval. For urgent or large-volume wholesale crimped wire mesh orders, expedited production options may be available. We recommend discussing your specific timeline with your chosen crimped wire mesh manufacturers during the inquiry phase.

Q4: Do you offer any warranty or quality assurance on your crimped wire mesh products?

A4: Reputable crimped wire mesh exporters and manufacturers adhere to strict quality control protocols and often provide a warranty against manufacturing defects. Our products are manufactured to international standards like ISO 9001 and undergo rigorous inspection. Specific warranty terms and conditions are provided with each order, ensuring peace of mind regarding product performance and durability. Comprehensive customer support is available for any queries post-purchase.

Conclusion: The Enduring Value of Crimped Wire Mesh

In summary, crimped wire mesh stands as a cornerstone material in modern industrial applications, valued for its superior strength, precise aperture control, and remarkable versatility. From its meticulously controlled manufacturing process, utilizing high-grade materials and adhering to international standards, to its deployment across critical sectors like mining, construction, and environmental engineering, this mesh consistently delivers reliable and efficient performance. The ability of crimped wire mesh manufacturers to offer custom crimped wire mesh solutions further enhances its utility, allowing for tailor-made applications that meet highly specific technical and operational demands.

Choosing a trusted crimped wire mesh supplier or crimped wire mesh factory means investing in a partnership that ensures not only high quality crimped wire mesh products but also comprehensive technical support and timely logistics, whether for a small, specialized order or large-scale wholesale crimped wire mesh procurement. As industries continue to evolve, the fundamental benefits of durability, precision, and adaptability offered by crimped wire mesh will ensure its continued relevance and growth as an indispensable industrial component. Its contribution to operational efficiency and long-term cost savings reinforces its position as a strategic material choice for discerning B2B stakeholders.

References

- American Society for Testing and Materials. (ASTM). Standards for Wire Cloth and Screens.

- International Organization for Standardization. (ISO). ISO 9001: Quality Management Systems – Requirements.

- National Association of Corrosion Engineers. (NACE). Standards for Corrosion Control.

- "Advances in Industrial Filtration Technologies." Journal of Process Engineering.

- "Material Science in Modern Construction." Structural Engineering Review.

This is the last article

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025