-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th11 . 27, 2024 04:57 Back to list

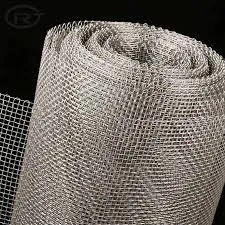

High-Quality Fine Wire Mesh Production Facilities and Their Advantages

The Importance of Fine Wire Mesh Factories in Modern Industries

Fine wire mesh factories play a crucial role in various industries by producing materials that are vital for numerous applications. These facilities specialize in the production of fine wire mesh, which is a versatile material used in a wide range of fields including manufacturing, construction, agriculture, and even electronics. The ability to customize the mesh according to specific needs makes these factories indispensable in today’s fast-paced industrial environment.

Understanding Fine Wire Mesh

Fine wire mesh is made from high-quality wires that are woven together to create a porous structure. This material can come in various thicknesses and openings, which allows for a broad spectrum of filtration, screening, and separation processes. The versatility of fine wire mesh means it can be used in applications as diverse as air and liquid filtration systems, sieving and classifying solid materials, and creating architectural features.

Types of Fine Wire Mesh

Fine wire mesh can be categorized into several types based on its weave, material, and application. Common materials include stainless steel, aluminum, and brass, each bringing unique properties to the finished product. Stainless steel wire mesh, for instance, is known for its durability and resistance to corrosion, making it ideal for environments that are subject to harsh conditions. On the other hand, brass wire mesh may be favored for its aesthetic appearance and antimicrobial properties.

The Manufacturing Process

fine wire mesh factories

The production of fine wire mesh involves several key steps. Initially, wire is drawn to the desired gauge, which dictates the thickness of the final mesh. Afterward, the wires are woven together using various methods such as plain weave, twill weave, or dutch weave, depending on the application. Quality control is a critical component at this stage, as the integrity of the weave directly affects the mesh's performance. Factories often use advanced machines and technologies to ensure precision and consistency in the product.

Applications of Fine Wire Mesh

The applications for fine wire mesh are nearly limitless. In the construction industry, it is commonly used for reinforcement in concrete to enhance strength and durability. In manufacturing, it can be employed for screening and separating materials in processes like mining and mineral processing. Agriculture also benefits from fine wire mesh in pest control, irrigation systems, and even in animal enclosures. Moreover, the electronics industry utilizes fine wire mesh in the production of screens and filters for various devices.

Environmental Impact

As industries become more environmentally conscious, fine wire mesh factories are also adapting to reduce their ecological footprint. Many manufacturers are now implementing sustainable practices such as recycling scrap metal from the production process and using eco-friendly packaging. Additionally, the longevity and durability of fine wire mesh serve to minimize waste, making it a more sustainable choice compared to many alternative materials.

Conclusion

In conclusion, fine wire mesh factories are essential contributors to the modern industrial landscape. Their ability to produce a wide range of customized products allows industries to tackle specific challenges effectively while promoting efficiency and sustainability. As technology progresses and the demand for specialized materials increases, the role of these factories in providing quality fine wire mesh will likely grow, ensuring that they remain integral to various sectors for years to come. The continuous evolution of production techniques and materials will further enhance the versatility and application of fine wire mesh, solidifying its place in the future of manufacturing and engineering.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025