-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th11 . 04, 2024 10:26 Back to list

Manufacturers of Versatile and Soft Stainless Steel Wire Mesh Solutions

Understanding the Significance of Flexible and Soft Stainless Steel Wire Mesh Factories

In the realm of industrial manufacturing and construction, the role of wire mesh is often understated. However, flexible and soft stainless steel wire mesh has proven to be an invaluable asset across various industries. This specialized material is characterized by its durability, versatility, and adaptability, making it essential for numerous applications. Factories that produce such wire mesh contribute significantly to the global supply chain, offering products that meet the highest standards of quality and performance.

The Importance of Stainless Steel Wire Mesh

Stainless steel wire mesh stands out due to its remarkable properties. Unlike ordinary wire mesh, stainless steel offers corrosion resistance, which ensures that it remains functional even in harsh environments. This feature is particularly valuable in industries such as construction, food processing, and pharmaceuticals, where hygiene and resistance to contaminants are critical. Flexible and soft variants of stainless steel wire mesh provide additional advantages, including ease of installation and maintenance.

The flexibility of the mesh allows it to conform to various shapes and structures, providing solutions in scenarios where rigidity may lead to complications. For instance, in architectural applications, flexible mesh can be used for decorative facades or as safety barriers, blending functionality with aesthetic appeal. In the agricultural sector, it is utilized in creating protective enclosures for livestock and crops, demonstrating its versatility.

Manufacturing Processes in Factories

The production of flexible and soft stainless steel wire mesh involves several intricate processes. Factories typically begin with the selection of high-quality stainless steel alloys, which form the foundation of the wire mesh. The manufacturing process generally includes wire drawing, where thick stainless steel rods are pulled through dies to achieve the desired thickness. Following this, the wires are woven together using various techniques, such as plain weave, twill weave, or Dutch weave, depending on the required specifications.

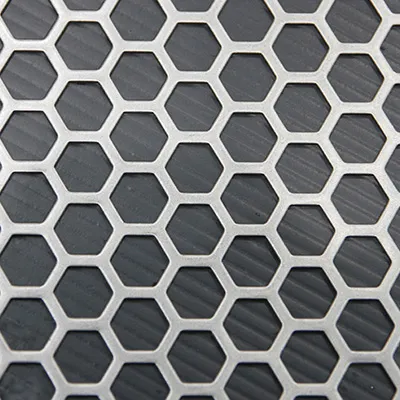

flexible and soft stainless steel wire mesh factories

Once woven, the mesh undergoes treatments to enhance its properties. Processes such as annealing not only improve the tensile strength of the mesh but also reduce brittleness, which is crucial for flexible applications. Factories must adhere to strict quality control measures throughout the production process to ensure that the final product meets industry standards and customer expectations.

Applications Across Industries

Flexible and soft stainless steel wire mesh finds its way into numerous applications, illustrating its far-reaching impact. In the construction industry, it is essential for reinforcing concrete structures, providing stability and support. The automotive sector makes use of wire mesh for filtration systems, ensuring that fluids and air remain free of contaminants.

In the realm of home and garden, stainless steel wire mesh serves as protective fencing, preventing unwanted pests while allowing for adequate airflow. Additionally, in the food industry, it is employed in the production of various equipment, such as sieves and strainers, where hygiene and easy cleaning are paramount.

Conclusion

As the demand for flexible and soft stainless steel wire mesh continues to grow globally, factories dedicated to this production play a critical role in meeting the needs of various industries. By leveraging advanced manufacturing techniques and ensuring high-quality output, these factories provide essential products that enhance safety, efficiency, and functionality across multiple sectors. The significance of stainless steel wire mesh cannot be understated, as it not only supports industrial applications but also contributes to innovative designs and solutions in everyday life. As technology evolves, we can expect further advancements in the capabilities and applications of flexible and soft stainless steel wire mesh, solidifying its status as a cornerstone material in modern manufacturing.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025