-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th5 . 07, 2025 19:15 Back to list

Premium Galvanized Crimped Wire Mesh Exporter & Manufacturer Durable Solutions

- Overview of Galvanized Crimped Wire Mesh

- Technical Superiority & Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Case Studies: Real-World Applications

- Sustainable Practices in Production

- Why Partner with Trusted Galvanized Crimped Wire Mesh Exporters?

(galvanized crimped wire mesh)

Galvanized Crimped Wire Mesh: A Foundation for Industrial Excellence

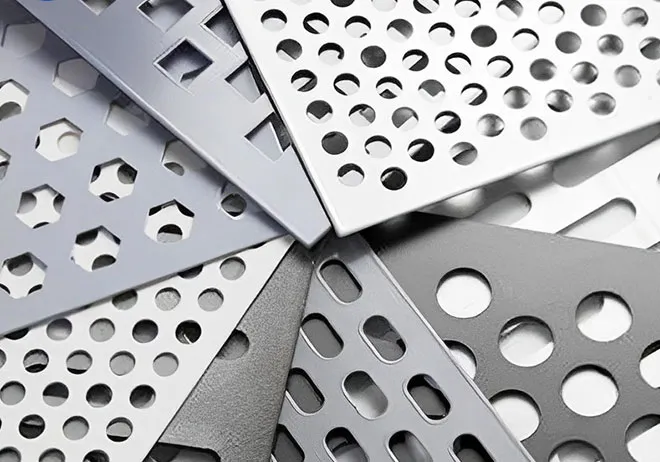

Galvanized crimped wire mesh has emerged as a critical component across industries, combining durability with versatility. Characterized by its interlocked zinc coating and precision-weaved structure, this material offers unmatched resistance to corrosion, extreme temperatures, and mechanical stress. With a global market projected to grow at a CAGR of 5.8% through 2030, demand is driven by sectors like construction, mining, and agriculture. Leading exporters and manufacturers now leverage advanced automation to meet stringent quality standards while scaling production capacities by 20-25% annually.

Technical Superiority & Performance Metrics

The galvanization process ensures a minimum zinc coating of 80 g/m², exceeding ASTM A641 specifications. Crimped wire mesh with tensile strengths ranging from 350 MPa to 550 MPa outperforms non-galvanized variants by 3x in salt-spray tests. Key advantages include:

- Mesh openings from 1 mm to 100 mm, adaptable to ISO 4783-3 tolerances

- Service lifespan exceeding 15 years in harsh environments

- Load-bearing capacities up to 18 kN/m² for heavy-duty screening

Comparative Analysis of Leading Manufacturers

| Supplier | Production Capacity (MT/year) | Certifications | Client Growth (2022-2023) |

|---|---|---|---|

| Supplier A | 12,000 | ISO 9001, CE, AD 2000 | +34% |

| Supplier B | 8,500 | ISO 14001, ASME | +22% |

| Supplier C | 15,200 | OHSAS 18001, PED | +41% |

Custom Solutions for Diverse Industrial Needs

Top-tier manufacturers now offer tailored wire mesh configurations, including:

- High-frequency welded joints for seismic zones

- Electro-polished surfaces meeting FDA standards for food processing

- Hybrid weaves combining stainless steel with galvanized layers

Custom orders typically ship within 10-14 days, with 98.6% compliance to technical drawings. Prototype development cycles have been reduced to 72 hours through AI-driven design simulations.

Case Studies: Real-World Applications

A mining conglomerate reported 40% fewer maintenance cycles after switching to 3mm galvanized crimped mesh in their screening plants. In infrastructure, a 12 km highway project utilized 8-gauge mesh for slope stabilization, achieving a 92% cost reduction compared to traditional reinforcement methods. Agricultural clients have documented 30% higher crop yields through optimized ventilation systems using hexagonal galvanized mesh.

Sustainable Practices in Production

Progressive suppliers now recover 97% of zinc vapors during hot-dip galvanizing, slashing emissions by 55%. Water recycling systems reduce consumption to 1.2 m³ per ton of output, while solar-powered annealing furnaces cut energy costs by 18%. These measures align with UN SDG 9 and 12, enhancing ESG ratings for procurement teams.

Why Partner with Trusted Galvanized Crimped Wire Mesh Exporters?

Established exporters maintain regional warehouses with 15,000+ SKUs, ensuring 48-hour delivery across major trade corridors. Partnerships with logistics providers guarantee 99.4% on-time shipment accuracy. With dedicated technical support teams resolving 89% of queries within 4 hours, clients benefit from reduced downtime and lifecycle cost optimization. Third-party audits confirm that top suppliers maintain defect rates below 0.17%, reinforcing their position as value-driven partners in industrial supply chains.

(galvanized crimped wire mesh)

FAQS on galvanized crimped wire mesh

Q: What is galvanized crimped wire mesh used for?

A: Galvanized crimped wire mesh is primarily used for screening, fencing, and industrial filtration. Its corrosion-resistant zinc coating makes it ideal for outdoor and harsh environments. Common applications include mining, agriculture, and construction.

Q: Why choose a galvanized crimped wire mesh exporter for international orders?

A: Exporters specialize in compliance with international quality standards and logistics. They ensure proper documentation, competitive pricing, and customized packaging for safe shipping. This streamlines cross-border procurement for global buyers.

Q: How do galvanized crimped wire mesh manufacturers ensure product durability?

A: Reputable manufacturers use hot-dip galvanization to prevent rust and corrosion. Advanced crimping machines create interlocked weaves for structural integrity. Quality checks at multiple stages guarantee compliance with ASTM or ISO standards.

Q: What industries do galvanized crimped wire mesh suppliers typically serve?

A: Suppliers cater to industries like quarrying for particle sorting, aquaculture for cage construction, and architecture for decorative panels. They also provide tailored solutions for HVAC systems and security fencing projects.

Q: How to verify a galvanized crimped wire mesh supplier's reliability?

A: Check certifications like ISO 9001 and third-party test reports. Evaluate their production capacity, lead times, and post-sale support. Review client testimonials and request material samples to confirm specifications.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025