-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th12 . 14, 2024 13:13 Back to list

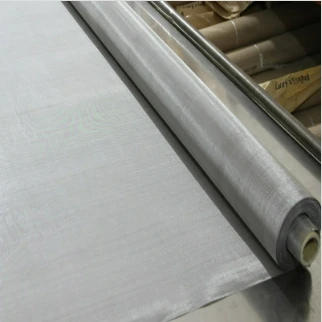

Suppliers of Perforated Stainless Steel Mesh for Various Applications and Industries

The Rise of Stainless Steel Perforated Metal Mesh A Guide to Suppliers

In recent years, the use of stainless steel perforated metal mesh has gained tremendous traction across various industries due to its versatility, durability, and aesthetic appeal. As more manufacturers and designers discover the benefits of this material, the demand has surged, prompting a notable increase in suppliers offering a wide range of perforated metal products. In this article, we will explore what stainless steel perforated metal mesh is, its applications, and what to consider when sourcing from suppliers.

Understanding Stainless Steel Perforated Metal Mesh

Stainless steel perforated metal mesh is created by punching holes into sheets of stainless steel. This process allows for a variety of hole shapes, sizes, and configurations, making it customizable to meet specific design and functional requirements. The stainless steel material itself is known for its corrosion resistance, strength, and longevity, making it an ideal choice for both indoor and outdoor applications.

Applications of Stainless Steel Perforated Metal Mesh

1. Architectural Elements In the architectural world, stainless steel perforated metal mesh is commonly used for decorative facades, canopies, and screens. Its sleek design combined with functionality allows architects to create visually appealing structures that can provide privacy while still allowing air and light to permeate.

2. Industrial Uses Many industries utilize perforated metal mesh for filtration and separation processes. In the manufacturing of chemicals, food, and pharmaceuticals, this mesh can be employed to filter out unwanted particles while allowing desired materials to pass through.

3. Safety and Security Stainless steel perforated sheets are often used in safety features such as guards, barriers, and enclosures. Their sturdy nature provides resistance against impact, which is crucial for equipment protection and worker safety in various environments.

4. Furniture Design Designers are increasingly incorporating perforated metal into modern furniture styles. Stools, tables, and lighting fixtures made from perforated stainless steel add a unique aesthetic and allow for intricate patterns that enhance the overall design.

5. Road and Building Traffic In civil engineering, stainless steel perforated metal mesh can be used in noise barriers and roadway applications where visibility and sound attenuation are needed.

metal stainless steel perforated metal mesh suppliers

Sourcing from Suppliers

When searching for suppliers of stainless steel perforated metal mesh, there are several factors to consider ensuring you partner with a reliable and quality provider

1. Quality of Materials Always verify the materials used by the supplier. Stainless steel should comply with relevant industry standards like ASTM or ISO to ensure its durability and resistance to corrosion. The grade of stainless steel—such as 304 or 316—will affect the mesh's properties, with 316 offering better corrosion resistance in harsher environments.

2. Customization Options Depending on your project, you may need specific hole sizes or patterns in your perforated metal mesh. Evaluate the supplier’s ability to customize dimensions and configurations to fit your design needs.

3. Experience and Reputation Research the supplier’s history in the industry. Experienced suppliers are more likely to provide quality products and customer service. Look for reviews, testimonials, and case studies that demonstrate their expertise and reliability.

4. Lead Times and Delivery Consider the supplier’s production times and their ability to meet your project deadlines. Timely delivery is crucial in preventing delays in your project’s development.

5. Pricing While cost should not be the only determining factor, it is essential to find a supplier that offers competitive pricing. Obtain quotes from multiple suppliers and compare them to ensure you’re getting a fair deal without compromising on quality.

6. Customer Service Good communication can significantly impact the sourcing process. Choose a supplier that is responsive and willing to address your questions and concerns effectively.

Conclusion

The demand for stainless steel perforated metal mesh continues to grow across various sectors, from architectural designs to industrial applications. As this material becomes more prevalent, selecting the right supplier is crucial to ensure quality, customization, and reliable delivery. By considering the factors outlined above, you can find a supplier that meets your project’s needs, allowing you to harness the full potential of stainless steel perforated metal mesh in your endeavors.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025