-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th9 . 19, 2024 08:06 Back to list

perforated metal panel factory

Perforated Metal Panel Factory A Gateway to Innovation and Versatility

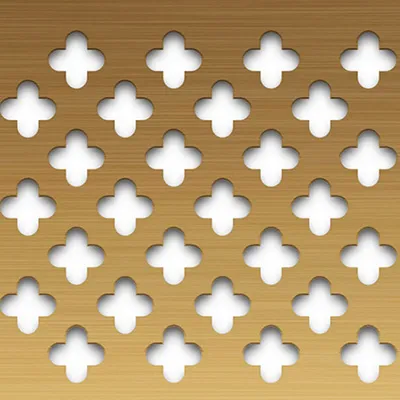

In the realm of modern architecture and design, perforated metal panels have emerged as a crucial element, offering both aesthetic appeal and functional benefits. Perforated metal panels consist of flat sheets of metal that have been punctured with a series of holes, creating a uniquely textured appearance while maintaining structural integrity. Factories specializing in the production of these panels play a pivotal role in advancing architectural possibilities and enhancing various industries.

One of the defining features of a perforated metal panel factory is its commitment to innovation. These factories utilize advanced manufacturing techniques and machinery to produce panels that cater to the diverse needs of architects and designers. By leveraging computer-aided design (CAD) software, manufacturers can create intricate patterns and custom hole configurations that align with specific project requirements. This level of customization allows architects to express their creativity while ensuring the panels serve their intended purpose.

The versatility of perforated metal panels makes them suitable for a wide range of applications. In exterior façades, they provide an appealing design element while facilitating airflow, natural light, and acoustic control. This is particularly important in urban environments where buildings often face challenges related to climate and noise. Similarly, these panels are utilized in interior spaces, serving as room dividers, decorative elements, or even acoustic panels to enhance sound quality within venues.

perforated metal panel factory

Moreover, perforated metal panels contribute to sustainability, as they can be made from recyclable materials like aluminum, steel, or copper. Many factories are dedicated to minimizing their environmental impact through efficient manufacturing practices and waste reduction. This aligns with the growing demand for eco-friendly building materials, allowing architects and builders to meet green building standards while also achieving elegant designs.

The quality of these panels is paramount, as they must withstand various environmental conditions. Perforated metal panel factories prioritize quality control, ensuring that each product meets industry standards and client specifications. This commitment to excellence not only reinforces the durability and performance of their products but also builds trust with their customers.

In conclusion, a perforated metal panel factory stands as a symbol of modern manufacturing, combining artistry with functionality. Its role in shaping contemporary architecture cannot be overstated, as it empowers designers and builders to push the boundaries of creativity while ensuring practical applications. With a focus on innovation, versatility, and sustainability, these factories are paving the way for a brighter, more aesthetic future in building design. As cities evolve and architectures change, perforated metal panels will undoubtedly continue to play a transformative role in the industry.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025