-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th10 . 15, 2024 22:55 Back to list

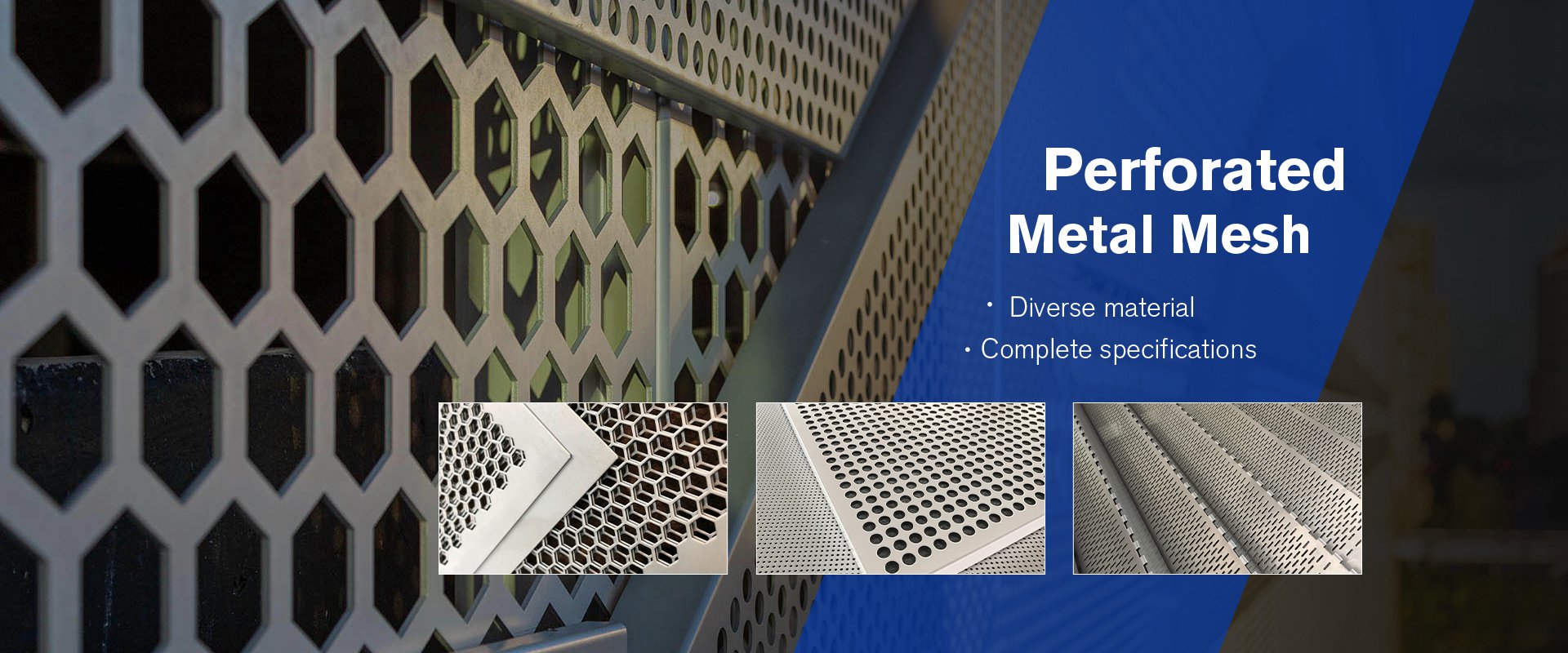

Factories Specializing in Perforated Panel Production and Design Solutions

The Surge in Popularity of Perforated Panels Innovations from Factories Around the Globe

In recent years, the construction and architectural industries have seen a growing trend towards the use of perforated panels

. These unique materials not only enhance aesthetic appeal but also offer functional benefits, making them a favored choice for designers and builders alike. With the global market expanding, perforated panel factories around the world are innovating and offering a diverse range of products that cater to various applications.Perforated panels are made from a variety of materials, including metal, plastic, and wood. They feature a series of holes or cut-outs that can be tailored in size, shape, and pattern. This flexibility allows architects and designers to create visually striking facades that can contribute to the identity of a building. Additionally, prefabricated perforated panels make construction processes more efficient, as they can be manufactured off-site and delivered ready for installation.

One of the primary advantages of perforated panels is their ability to provide natural ventilation while maintaining privacy and aesthetics. This is particularly beneficial in urban environments where space is at a premium. Factories are innovating to create panels that not only allow for airflow but also incorporate sustainable design principles. For example, perforated metal panels can reduce energy consumption by minimizing heat buildup while allowing daylight to filter through, thereby reducing dependency on artificial lighting.

Moreover, the acoustic benefits of perforated panels cannot be overlooked. In crowded urban centers, noise pollution is a significant concern. Perforated panels can be designed to absorb sound, making them ideal for use in concert halls, theaters, and residential spaces where acoustics play a crucial role. As a result, many factories are now focusing on the development of panels that combine aesthetic appeal with superior acoustic performance.

perforated panel factories

The customization options available through perforated panel manufacturers have also increased significantly. Today, advanced manufacturing techniques such as CNC machining and laser cutting enable factories to produce highly intricate designs. This provides architects the freedom to push creative boundaries and implement unique patterns that reflect the character of a building. Customized panels can also serve as branding elements, further enhancing the visual impact of commercial structures.

In addition to aesthetics and functionality, sustainability has become a driving force behind the production of perforated panels. Many manufacturers are now sourcing materials from recycled or sustainable origins, such as aluminum or sustainably harvested wood. The ability to create environmentally friendly products is not only advantageous from a marketing standpoint but also aligns with the global push towards greener building practices. Factories are increasingly adopting sustainable manufacturing processes, reducing waste and energy consumption during production.

Globalization has also played a significant role in the expansion of the perforated panel market. International collaborations between architects, designers, and manufacturers allow for the sharing of innovative ideas and best practices. This cross-pollination of concepts has led to the emergence of new design trends and applications for perforated panels, making them an integral part of contemporary architecture worldwide.

As the demand for perforated panels continues to rise, so does the competition among manufacturers. This has spurred advancements in technology and design, resulting in better quality products at more competitive prices. Factories are now investing in research and development to explore new materials, coatings, and technologies that enhance the durability and performance of perforated panels.

In conclusion, the evolution of perforated panels reflects a broader trend in architecture that values both beauty and functionality. With an increasing emphasis on sustainability, acoustics, and innovative design, perforated panel factories are well-positioned to meet the demands of modern construction projects. As we look towards the future, it is clear that these versatile materials will play a pivotal role in shaping the built environment, offering endless possibilities for creativity and expression in architectural design. Whether for residential, commercial, or industrial applications, the versatility and appeal of perforated panels are sure to keep them at the forefront of architectural innovation.

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025