-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th12 . 12, 2024 09:59 Back to list

wire mesh panels manufacturer

Wire Mesh Panels Manufacturer Enhancing Versatility and Durability

Wire mesh panels are a hallmark of modern industrial and commercial applications. Their versatility and strength have made them a preferred choice across various sectors, from agriculture and construction to transportation and security. As a wire mesh panels manufacturer, one plays a pivotal role in supplying these essential components to meet the demands of different industries.

Understanding Wire Mesh Panels

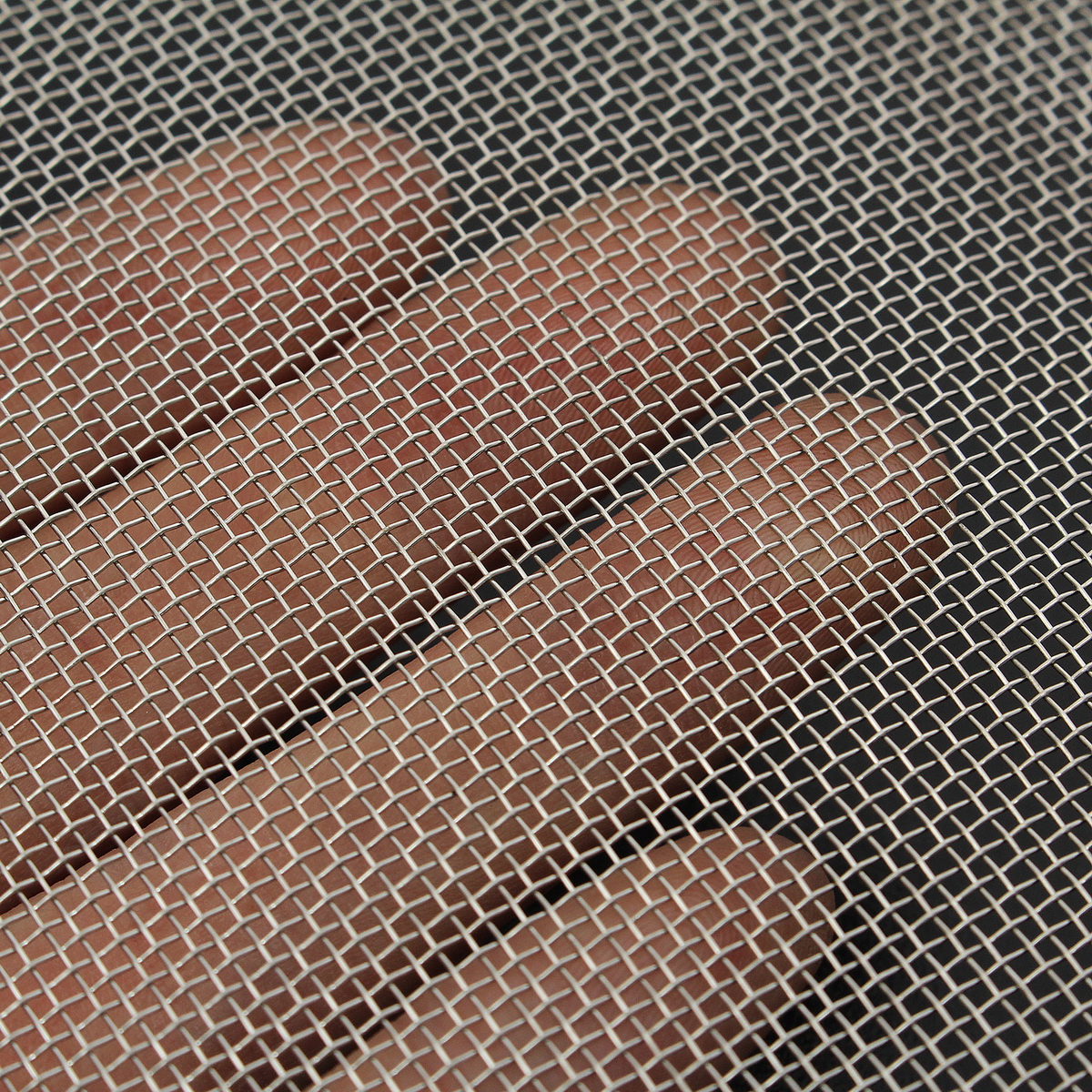

Wire mesh panels are made from interwoven wire strands, creating a grid that is both flexible and durable. These panels are designed for a multitude of applications, providing solutions for containment, safety, and support. They come in a variety of materials—such as stainless steel, galvanized steel, or aluminum—each offering distinct advantages in terms of strength, corrosion resistance, and weight.

The production of wire mesh panels involves precise manufacturing processes. Typically, wires are drawn to specific gauges, then woven or welded together to create the desired panel size and design. High-quality wire mesh panels can be tailored to meet specific client needs, including custom sizes, hole patterns, and finishes.

Applications of Wire Mesh Panels

The applications of wire mesh panels are expansive and varied. In the agricultural sector, they are used for fencing livestock, providing a secure environment while allowing for visibility and ventilation. In construction, wire mesh panels serve as reinforcement for concrete structures, ensuring durability and stability. They are also widely used in landscaping for decorative as well as functional purposes, such as garden trellises and retaining walls.

Additionally, wire mesh panels play a crucial role in security. Many manufacturers produce panels that are specifically designed for fencing commercial properties, warehouses, and residential areas. These panels can be fabricated with added features, such as barbs or spikes, to enhance security features.

In the industrial space, wire mesh panels are utilized in the production of shelving, storage solutions, and even conveyor systems. Their sturdy design allows them to bear substantial loads, making them perfect for heavy-duty usage. Furthermore, these panels are often used in ventilation systems, allowing air to flow freely while preventing larger objects from passing through.

Quality and Standards in Production

wire mesh panels manufacturer

As a wire mesh panels manufacturer, maintaining high quality and adhering to industry standards is of utmost importance. Products must undergo rigorous testing for strength, durability, and reliability. Many manufacturers comply with international quality standards such as ISO 9001, which helps ensure client satisfaction and product consistency.

Investing in advanced technology and skilled labor is essential for producing high-quality wire mesh panels. Automation in the manufacturing process can help minimize human error, enhance production speed, and ensure precise dimensions. Additionally, employing skilled technicians ensures that every product meets the high standards required by various industries.

Customization Options

One of the key advantages of working with a wire mesh panels manufacturer is the ability to customize products to meet specific needs. Clients can request unique sizes, materials, and finishes that cater to their particular requirements. Whether it’s for aesthetic purposes in home decor or functional demands in industrial applications, customization helps ensure that the wire mesh panels serve their intended purpose efficiently.

Additionally, many manufacturers offer design consultation services to guide clients in selecting the most suitable wire mesh solutions for their projects. This collaborative effort can lead to innovative applications and more effective use of the products.

Environmental Considerations

As industries move towards more sustainable practices, wire mesh panel manufacturers are also adapting. By using recyclable materials and implementing environmentally friendly manufacturing processes, they can reduce their carbon footprint. This commitment to environmental sustainability not only meets regulatory requirements but also appeals to eco-conscious consumers who prioritize sustainability in their purchasing decisions.

Conclusion

Wire mesh panels are indispensable across multiple sectors, and the role of a wire mesh panels manufacturer is critical in providing these versatile solutions. With a focus on quality, customization, and sustainability, manufacturers can meet the diverse needs of their clients while contributing to industry advancements. As technology evolves and applications expand, the future of wire mesh panels appears bright, signaling continued growth and innovation within this essential manufacturing domain.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025