-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Th12 . 24, 2024 10:02 Back to list

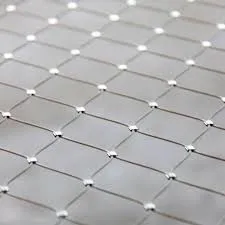

Stainless Steel 316 304 Wire Mesh Manufacturer for Durable Industrial Solutions

Wire Mesh SS 316 and 304 Manufacturer

In industries ranging from food processing to chemical production, the use of high-performance materials is paramount. Stainless steel wire mesh, particularly of grades SS 316 and SS 304, has emerged as an essential component in various applications due to its superior resistance to corrosion, durability, and structural integrity. This article delves into the significance of these materials, the manufacturing process, and their various applications.

Understanding SS 304 and SS 316

Stainless steel is an alloy primarily composed of iron, chromium, and nickel. The differences between SS 304 and SS 316 come from their specific chemical compositions. SS 304 contains 18% chromium and 8% nickel, making it one of the most commonly used stainless steel grades. It exhibits excellent corrosion resistance in various environments, making it ideal for applications in food processing, dairy, and architecture.

On the other hand, SS 316 is distinguished by the addition of molybdenum (2-3%), which enhances its resistance to chlorides and other corrosive agents. Consequently, SS 316 is often preferred in marine environments, chemical processing, and situations where the wire mesh may be exposed to harsh conditions. Its resistance to pitting and crevice corrosion makes it a robust choice for more demanding applications.

Manufacturing Process of Stainless Steel Wire Mesh

The manufacturing of stainless steel wire mesh involves several key processes to ensure the final product meets both quality and performance standards. The primary steps include

1. Wire Drawing This process begins with stainless steel rods, which are drawn through a series of dies to reduce their diameter and increase their length. The wire gauge needed for the specific application dictates how this step is conducted.

2. Weaving The drawn wire is then woven into mesh. This can be accomplished through various techniques, including plain weave, twilled weave, and Dutch weave. Each method provides different characteristics and is chosen based on the required specifications, such as mesh size and wire diameter.

3. Finishing After weaving, the wire mesh undergoes various finishing processes. These can include pickling (to remove surface imperfections), passivation (to enhance corrosion resistance), and even coating in some cases to further improve durability.

wire mesh ss 316 304 manufacturer

4. Quality Control Rigorous quality control measures are implemented throughout the manufacturing process. Each batch of wire mesh is tested for weave integrity, dimensional accuracy, and resistance to corrosion, ensuring compliance with industry standards.

Applications of Stainless Steel Wire Mesh

The versatility of SS 316 and SS 304 wire mesh lends itself to a multitude of applications

- Food and Beverage Industry In food processing plants and breweries, wire mesh plays a crucial role in filtration, sieving, and separation processes. SS 304 is often utilized in less corrosive environments, while SS 316 is preferred in areas exposed to harsher cleaning agents or salty air.

- Chemical Industry SS 316 wire mesh is a go-to material in chemical processing for its ability to withstand aggressive chemicals. It is often used in process equipment, screens, and filters.

- Pharmaceuticals Sterility is vital in pharmaceutical applications, making SS 316 wire mesh ideal for use in filtration systems and containment structures, where contamination must be minimized.

- Construction and Architecture Both grades of stainless steel wire mesh serve decorative and practical functions in construction, providing aesthetic appeal while ensuring structural safety in buildings and infrastructure.

Conclusion

The choice between SS 316 and SS 304 wire mesh ultimately depends on the specific requirements of the application. With a reliable manufacturer of these high-quality materials, industries can benefit from enhanced performance, longevity, and safety. Understanding the unique properties and applications of stainless steel wire mesh is crucial for those looking to optimize their production processes and ensure compliance with industry standards. Whether for filtration, reinforcement, or aesthetic purposes, investing in high-quality wire mesh is a decision that pays dividends in operational efficiency and durability.

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025