-

+86 15030157877

-

sales@galvanizedmetalmesh.com

فبراير . 19, 2025 01:58 Back to list

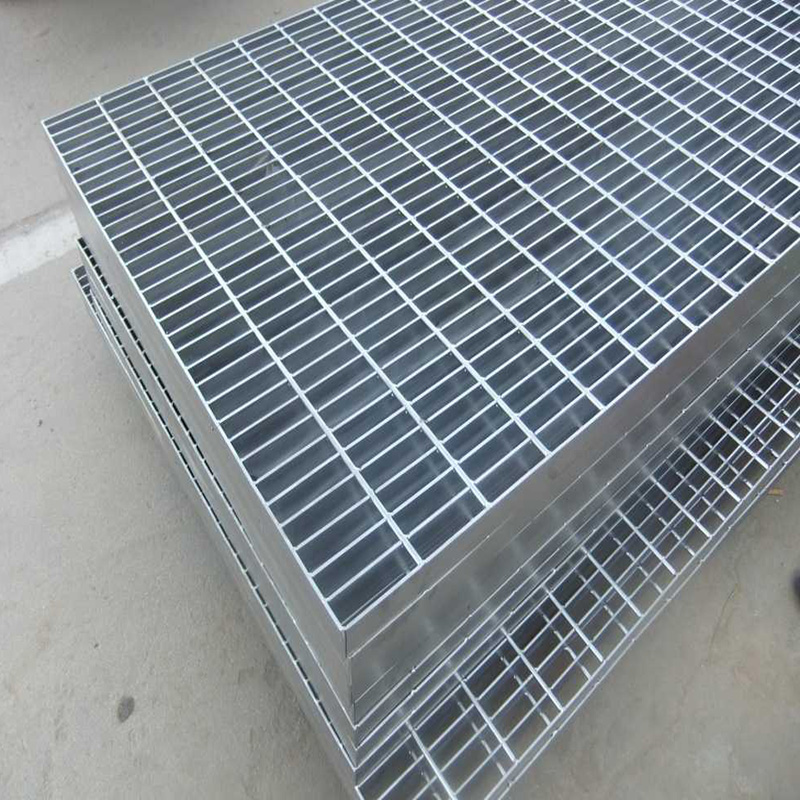

high quality iron wire mesh price

Choosing the right iron wire mesh involves more than just selecting a product that suits your visual or functional needs; it's about ensuring quality, durability, and, importantly, cost-effectiveness tailored to specific applications. For businesses and projects where investment in quality materials is critical, understanding the price structure of high-quality iron wire mesh is essential. Here’s a comprehensive guide to navigating this important aspect, enriched with experience, expertise, authority, and trustworthiness, providing valuable insights into what impacts these costs.

4. Supply Chain and Vendor Reputation The vendor you choose also impacts the price of high-quality iron wire meshes. Established and reputable suppliers, often commanding a premium, bring a level of assurance regarding product authenticity and quality assurance practices. Their experience and expertise also mean they can provide expert guidance tailored to unique project needs. Vendor credibility contributes significantly to trustworthiness, ensuring that one chooses meshes that align with the project’s durability and quality expectations. 5. Economic Factors and Market Dynamics As with many commodities, the price of iron materials is subject to global economic factors, including trade policies and raw material availability. It’s critical to stay informed about market trends, as fluctuations can impact material costs considerably. Having a trusted partner who provides timely insights can help predict and mitigate unexpected cost shifts, ensuring your project remains within budget. When procuring high-quality iron wire mesh, assessing it from a holistic perspective that merges cost with practical application is vital. Engage in thorough material quality checks, validate the manufacturing processes, and ensure that any additional specifications align with practical needs. Trust in established suppliers who not only prioritize quality but also offer expert guidance rooted in thorough industry understanding. The savvy project manager or goods procurer will balance these aspects — only then will you ensure that you’re not just purchasing a product, but an investment in quality that pays dividends in performance and durability, reinforcing both the integrity and cost-effectiveness of your venture.

4. Supply Chain and Vendor Reputation The vendor you choose also impacts the price of high-quality iron wire meshes. Established and reputable suppliers, often commanding a premium, bring a level of assurance regarding product authenticity and quality assurance practices. Their experience and expertise also mean they can provide expert guidance tailored to unique project needs. Vendor credibility contributes significantly to trustworthiness, ensuring that one chooses meshes that align with the project’s durability and quality expectations. 5. Economic Factors and Market Dynamics As with many commodities, the price of iron materials is subject to global economic factors, including trade policies and raw material availability. It’s critical to stay informed about market trends, as fluctuations can impact material costs considerably. Having a trusted partner who provides timely insights can help predict and mitigate unexpected cost shifts, ensuring your project remains within budget. When procuring high-quality iron wire mesh, assessing it from a holistic perspective that merges cost with practical application is vital. Engage in thorough material quality checks, validate the manufacturing processes, and ensure that any additional specifications align with practical needs. Trust in established suppliers who not only prioritize quality but also offer expert guidance rooted in thorough industry understanding. The savvy project manager or goods procurer will balance these aspects — only then will you ensure that you’re not just purchasing a product, but an investment in quality that pays dividends in performance and durability, reinforcing both the integrity and cost-effectiveness of your venture.

Latest news

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025