-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Úno . 16, 2025 04:37 Back to list

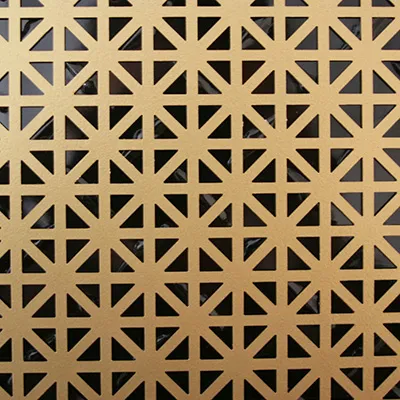

custom crimped mesh

Custom crimped mesh, an essential element in various industrial applications, offers a unique blend of strength, versatility, and durability. This product is tailor-made to meet the specific demands of clients across different sectors, providing innovative solutions for numerous challenges. Equipped with advanced features, custom crimped mesh has become a highly sought-after product among professionals seeking efficiency and reliability.

Establishing trust in this product is crucial for industry leaders and stakeholders. Understanding its comprehensive testing phases, which include rigorous stress and load testing, plays an integral part in its value proposition. Collaborations with reputable certification bodies and constant innovation help reinforce the authority and credibility of manufacturers producing custom crimped mesh. Furthermore, the installation of custom crimped mesh is a straightforward process that does not demand specialized tools or excessive manpower. This ease of installation supports quick deployment in projects, saving time and reducing labor costs. Coupled with minimal maintenance needs, it's an optimal solution for businesses keen on reducing overheads while enhancing operational efficiency. The eco-friendly aspect of custom crimped mesh cannot be overlooked. The materials used are often recyclable, minimizing environmental impact and aligning with global sustainability initiatives. Companies focusing on green certifications and sustainable construction find this characteristic particularly appealing, aligning with broader eco-friendly goals and enhancing corporate social responsibility profiles. Trustworthiness is built through consistent delivery of quality and performance. Customer testimonials and case studies serve as testimony to the reliability of custom crimped mesh. They provide insights into real-world applications and outcomes, enabling potential clients to make informed purchasing decisions. Transparent communication regarding specifications, service life, and performance expectations further cultivates a trustworthy relationship between manufacturers and consumers. In conclusion, custom crimped mesh stands out as a versatile and enduring solution across various sectors. Its unique combination of customizability, strength, and resilience makes it an indispensable tool. With a firm grounding in quality assurance, environmental responsibility, and operational efficiency, it holds significant promise for continued innovation and application in the future. For those seeking reliable and adaptable solutions, investing in custom crimped mesh represents a strategic choice driven by informed expertise and authoritative insights.

Establishing trust in this product is crucial for industry leaders and stakeholders. Understanding its comprehensive testing phases, which include rigorous stress and load testing, plays an integral part in its value proposition. Collaborations with reputable certification bodies and constant innovation help reinforce the authority and credibility of manufacturers producing custom crimped mesh. Furthermore, the installation of custom crimped mesh is a straightforward process that does not demand specialized tools or excessive manpower. This ease of installation supports quick deployment in projects, saving time and reducing labor costs. Coupled with minimal maintenance needs, it's an optimal solution for businesses keen on reducing overheads while enhancing operational efficiency. The eco-friendly aspect of custom crimped mesh cannot be overlooked. The materials used are often recyclable, minimizing environmental impact and aligning with global sustainability initiatives. Companies focusing on green certifications and sustainable construction find this characteristic particularly appealing, aligning with broader eco-friendly goals and enhancing corporate social responsibility profiles. Trustworthiness is built through consistent delivery of quality and performance. Customer testimonials and case studies serve as testimony to the reliability of custom crimped mesh. They provide insights into real-world applications and outcomes, enabling potential clients to make informed purchasing decisions. Transparent communication regarding specifications, service life, and performance expectations further cultivates a trustworthy relationship between manufacturers and consumers. In conclusion, custom crimped mesh stands out as a versatile and enduring solution across various sectors. Its unique combination of customizability, strength, and resilience makes it an indispensable tool. With a firm grounding in quality assurance, environmental responsibility, and operational efficiency, it holds significant promise for continued innovation and application in the future. For those seeking reliable and adaptable solutions, investing in custom crimped mesh represents a strategic choice driven by informed expertise and authoritative insights.

Latest news

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025