-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Úno . 04, 2025 00:50 Back to list

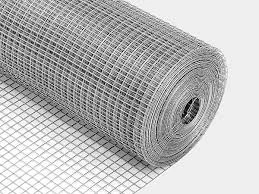

custom galvanized square woven wire mesh

Custom galvanized square woven wire mesh offers a versatile and robust solution for various industrial, commercial, and residential applications. As an experienced industry professional, understanding the intricate details of this product is crucial to making informed purchasing and application decisions. Below, we'll delve into the nuances of custom galvanized square woven wire mesh, highlighting its benefits, applications, and why it stands out in the market.

Trustworthiness in the production of custom galvanized square woven wire mesh is reinforced by third-party testing and certifications. Reputable manufacturers provide mesh products that comply with international quality standards such as ISO and ASTM. This adherence to stringent quality checks ensures that the wire mesh performs reliably under expected environmental stresses. Clients can rely on these products for safety and structural reliability, which is especially critical in high-stakes applications. The applications of custom galvanized square woven wire mesh are vast and varied. In architecture, it is frequently used in the design of building facades, offering not only functional benefits such as ventilation and shading but also an aesthetic appeal with its clean, geometric lines. Industrial sectors utilize this mesh in machinery guards, filtration systems, and transportation storage, valued for its strength and resilience. Agricultural use includes animal enclosures and crop protection, where longevity and resistance to the elements are paramount. Choosing custom galvanized square woven wire mesh is a decision backed by science and experience. It is an investment in durability and protection, ensuring that environments and projects remain secure against wear and potential hazards. As experts in the field continuously innovate and refine manufacturing techniques, the adaptability and efficacy of these meshes continue to expand, meeting the growing demands of modern infrastructure and design. In summary, custom galvanized square woven wire mesh represents a confluence of expert engineering, innovative craftsmanship, and reliable material science. For those seeking a product that combines functionality with adaptability, this mesh stands unrivaled. As the industry continues to advance, this product remains a cornerstone of construction and manufacturing projects worldwide, distinguished by its enduring quality and utility.

Trustworthiness in the production of custom galvanized square woven wire mesh is reinforced by third-party testing and certifications. Reputable manufacturers provide mesh products that comply with international quality standards such as ISO and ASTM. This adherence to stringent quality checks ensures that the wire mesh performs reliably under expected environmental stresses. Clients can rely on these products for safety and structural reliability, which is especially critical in high-stakes applications. The applications of custom galvanized square woven wire mesh are vast and varied. In architecture, it is frequently used in the design of building facades, offering not only functional benefits such as ventilation and shading but also an aesthetic appeal with its clean, geometric lines. Industrial sectors utilize this mesh in machinery guards, filtration systems, and transportation storage, valued for its strength and resilience. Agricultural use includes animal enclosures and crop protection, where longevity and resistance to the elements are paramount. Choosing custom galvanized square woven wire mesh is a decision backed by science and experience. It is an investment in durability and protection, ensuring that environments and projects remain secure against wear and potential hazards. As experts in the field continuously innovate and refine manufacturing techniques, the adaptability and efficacy of these meshes continue to expand, meeting the growing demands of modern infrastructure and design. In summary, custom galvanized square woven wire mesh represents a confluence of expert engineering, innovative craftsmanship, and reliable material science. For those seeking a product that combines functionality with adaptability, this mesh stands unrivaled. As the industry continues to advance, this product remains a cornerstone of construction and manufacturing projects worldwide, distinguished by its enduring quality and utility.

Next:

Latest news

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025