-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 17, 2025 13:05 Back to list

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

Expanded Metal Mesh is a key solution in the industrial manufacturing industry, specifically within metal products and Metal mesh products. This article explores how HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Expanded Metal Mesh Overview

- Benefits & Use Cases of Expanded Metal Mesh in Metal mesh products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial manufacturing

- Conclusion on Expanded Metal Mesh from HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.

Expanded Metal Mesh Overview

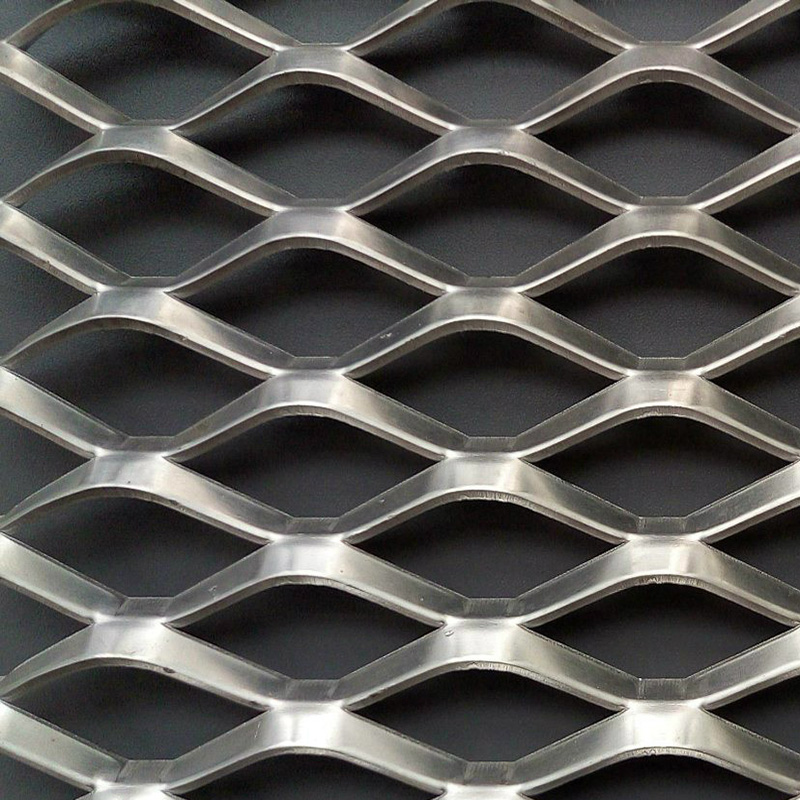

Expanded metal mesh is produced by slitting and stretching a single metal sheet to form uniform openings—typically diamond, hexagonal, or special patterns—without welding or weaving. This process creates a high-strength, lightweight, and slip-resistant mesh that is widely used across industrial manufacturing for guarding, screening, filtration, ventilation, walkways, racking, and architectural facades. Standard (raised) and flat expanded metal mesh are the two primary forms; flattened mesh is calendered for a smooth, planar surface ideal for fabrication and aesthetics. Available materials include low-carbon steel, pre-galvanized steel, hot-dip galvanized steel, aluminum, and stainless steel (304/316).

- Typical specs: thickness 0.5–6.0 mm, strand width 0.5–8.0 mm, SWD/LWD 4–100 mm, open area 30–80%, sheets or coils. Finishes include mill, galvanized, and powder coated expanded metal mesh for enhanced corrosion resistance and brand-matched colors.

- Customization: custom expanded metal mesh sheet sizes, custom flat expanded metal mesh, and tailored patterns to meet airflow, visibility, or load-bearing targets.

- HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. is a dependable expanded metal mesh manufacturer and supplier with rigorous process control, consistent aperture tolerances, and responsive engineering support for B2B programs.

Benefits & Use Cases of Expanded Metal Mesh in Metal mesh products

In metal mesh products, expanded metal mesh shines where strength, ventilation, and safety converge. Typical applications include machine guards, safety walkways and catwalks, fencing and perimeter security, anti-slip tread plates, HVAC screens, filtration pre-screens, shelving and racking, acoustic panels, and architectural cladding. Because it’s formed from a continuous sheet, there are no welds that can fail; strands deliver excellent rigidity and impact resistance at a much lower weight than solid plate.

- Competitive advantages: superior strength-to-weight, high open area for airflow/light, non-slip surface, cost-effective coverage per square meter, and easy fabrication (cutting, bending, framing).

- Finish options: powder coated expanded metal mesh supports corporate colors and enhanced corrosion resistance; galvanized or stainless options thrive in outdoor or corrosive settings.

- HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. offers custom expanded metal mesh and wholesale expanded metal mesh sheet programs, balancing MOQ, lead time, and specification control—ideal for OEMs, fabricators, and project contractors.

Cost, Maintenance & User Experience

Total cost of ownership improves with expanded metal mesh because the slit-and-stretch process minimizes waste versus perforated plate, while open area reduces the need for auxiliary ventilation hardware. The mesh’s inherent stiffness often allows lighter support structures, lowering installed cost. For maintenance, galvanized and powder-coated surfaces deliver long service intervals; stainless grades minimize lifecycle touch-ups in aggressive environments.

- Customers in machinery guarding report faster installation and fewer field adjustments with flat expanded metal mesh due to uniform thickness and stable geometry, cutting labor hours.

- A typical ROI scenario: switching from perforated sheet to expanded mesh can reduce material consumption by 10–30% and weight by up to 50%, improving handling and transport costs.

- HEBEI WEICHUN’s wholesale expanded metal mesh programs streamline procurement with consistent quality, protective packaging, and dependable lead times—supporting both repeat orders and custom expanded metal mesh sheet runs.

Sustainability & Market Trends in industrial manufacturing

Sustainability priorities are accelerating demand for expanded metal mesh. The process converts a solid sheet into coverage with virtually no scrap, conserving raw material. Steel and aluminum substrates are recyclable, and powder coating options can align with low-VOC targets and common compliance requirements. In infrastructure, energy, and architecture, specifiers increasingly favor high open-area materials that reduce weight and improve natural ventilation and light.

- Market trends: growth in safety platforms, modular enclosures, and façade solutions; tighter tolerances and color-matched finishes; and global sourcing via reliable expanded metal mesh exporters.

- Positioned as an agile expanded metal mesh factory and supplier, HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. emphasizes material efficiency, responsible finishing, and continuous process improvement to support customers’ ESG objectives while maintaining cost competitiveness.

Conclusion on Expanded Metal Mesh from HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.

Expanded metal mesh delivers a rare mix of strength, ventilation, safety, and value for industrial manufacturing. From machine guards and platforms to architectural cladding, HEBEI WEICHUN WIRE MESH TRADE CO.,LTD. supplies custom expanded metal mesh solutions with dependable quality and on-time delivery—backed by a wholesale expanded metal mesh supply chain designed for B2B scale.

- Partner with a proven expanded metal mesh manufacturer and exporter for your next project.

- Contact us: email: sales@galvanizedmetalmesh.com

- Visit our website: https://www.galvanizedmeshproducts.com

-

Stainless Steel Wire Mesh | 304/316, Factory Direct Prices

NewsNov.17,2025

-

Stainless Steel Wire Mesh – Durable, Rust-Resistant, Exact

NewsNov.17,2025

-

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

NewsNov.17,2025

-

Security Window Screen Mesh | Stainless Steel, Anti-Theft

NewsNov.17,2025

-

Anti Bird Spikes Exporter – Durable Humane OEM Wholesale

NewsNov.17,2025

-

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

NewsNov.11,2025